DECENTRALIZED DISTRIBUTION

Page 98

Page 99

Page 100

Page 103

If you've noticed an error in this article please click here to report it so we can fix it.

a key feature of Sainsbury's planned expansion

By John Darker, AmBim WHEN a business expands, its management sooner or later faces two problems: getting larger premises and additional transport. The process—happily for the commercial vehicle industry—is not at all infrequent. The problems presented to a small shopkeeper whose turnover justifies opening another shop and buying an additional vehicle are comprehensible. Most of us can appreciate the risk involved and the adventurous "kick" that rewards successful expansion.

The rapid expansion of a multiple grocery chain as large as that of J. Sainsbury Ltd., whose turnover virtually doubled between 1960 and 1967 and now approaches £130 m. a year, involves problems of logistics, of forward planning and forecasting and the detailed application of managerial expertise on a scale sufficient to daunt the toughest entrepreneur. For the stakes are high: errors in planning can prove costly yet wise judgment reflected in well-designed premises properly located for their purpose can form the springboard for yet more spectacular advances.

Realizing the need for a greatly enlarged distributive set-up as long ago as 1959, Sainsbury acquired the old RAOC depot at Buntingford, a familiar landmark to many lorry drivers passing along A10. A greatly increased volume of business and worsening traffic conditions were imposing impossible demands on the 70-year-old Blackfriars central depot and the Buntingford purchase was the first move towards decentralization of the distributive function.

It was possible to make almost immediate use of the 7+ acre RAOC depot with minor alterations and it was so used for the distribution of non-perishable goods serving about 90 branches until it was closed to allow work to proceed on the building of the new enlarged depot in 1965.

The first major distribution depot in Sainsbury's decentralization plan was opened at Basingstoke in 1964. Detailed studies to determine the most economical site for this southern depot pinpointed No. 1 runway at London Airport, Heathrow! After sites near Slough had been rejected the Basingstoke location was chosen. Buntingford is the second decentralized depot and a third is planned in Charlton, South East London.

The decision to develop Buntingford was taken in 1964 when land was purchased to increase the site to a total of 33 acres. (The projected Buntingford by-pass is likely to skirt the eastern boundary.)

The two original buildings of the ordnance depot occupied 60,000 square feet. The scale of expansion can be imagined by the floor

area of the new building, now approaching completion, which covers some 500,000 square feet. It comprises perishable and nonperishable goods warehouses, cold stores, offices and maintenance workshops for mechanical handling equipment, battery charging rooms, staff restaurant and cloakrooms as well as an area reserved for future• packaging operations. A separate building houses the vehicle repair shop, with an adjacent air-conditioned paint spraying shop and a mechanical vehicle washing plant.

In total, the new buildings occupy 8+ acres while roadways and parking spaces take up a further 12. Staff amenities—when the depot is completed 1,500 workers will be employed there—include football pitches, a restaurant and a recreation hall for badminton, table tennis, darts and so on.

Well-sited depot The nearly square main warehouse, with a clear internal height of 25 ft., is built largely of factory-produced lightweight concrete panels. Despite its great size the building does not seem oppressively bulky or slab-sided from inside or outside. A more pleasantly sited depot would be hard to imagine and I was not surprised to learn that a good crosssection of staff from the Blackfriars depot have volunteered to transfer to Buntingford.

An unusual roof design utilizes precast concrete beams incorporating internal suspension cables. Over half the area of the building these roof beams support alternate high

and low level roof slabs, forming a profile to provide light and air over the dry goods warehouse. To the same beams an insulated ceiling is affixed over the "perishables" (refrigerated) section of the building. Extensive areas of under-floor heating have been installed in the floor of the refrigerated section. I must confess this intrigued me, for I imagined that the colder a cold store was, the better! The underfloor heating, in fact, prevents the ground freezing under the sub-zero temperatures. Outside the building there is an impressive battery of electric points into which loaded refrigerated lorries will be "plugged" during the night, to maintain the refrigeration, ready for collection by their drivers in the morning. The two covered loading and unloading bays are capable of handling up to 75 vehicles at one time.

There can be few refrigerated stores in this country larger than the Sainsbury Buntingford premises which have a capacity' of 2,185,000 cu. ft.—equal in volume to about 360,000 domestic refrigerators. The temperature range is from —5°F for quick frozen food storage to 35 /40° in the perishable food warehouse.

Communications in so large a depot present considerable problems which need to be thoroughly thought through before building commences. Personnel circulation within the main building at Buntingford is at first floor level with cloakrooms, offices and laboratories forming a central spine connecting the production area to the staff restaurant. Access for staff and visitors is direct from the car park (with accommodation for some 600, cars for employees alone) to first floor level providing complete segregation of pedestrians and commercial vehicles within the depot.

A document tube conveyor links all vital communications points, and key personnel are equipped with two-way radio, using miniaturized equipment—a very necessary innovation if urgent internal or external calls are to be handled promptly. On a selected circuit, should any 'phone remain unanswered for 30 seconds an automatic interceptor device re-routes the call to a message-receiving centre. Similarly, a 'phone call to an engaged line is re-routed to a series of planned alternative lines until a disengaged one is found. There is a private Telex line to the Blackfriars headquarters and a further Telex connection to the normal public network.

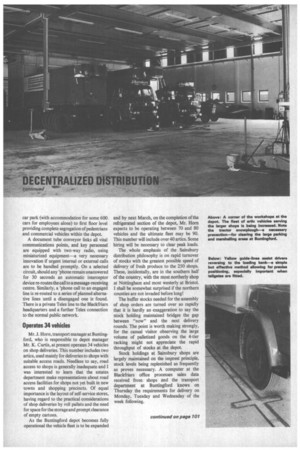

Operates 34 vehicles

Mr..). Horn, transport manager at Buntingford, who is responsible to depot manager Mr. K. Curtis, at present operates 34 vehicles on shop deliveries. This number includes two attics, used mainly for deliveries to shops with suitable access roads. Needless to say, road access to shops is generally inadequate and I was interested to learn that the estates department make representations about road access facilities for sherps not yet built in new towns and shopping precincts. Of equal importance is the layout of self-service stores, having regard to the practical considerations of shop deliveries by roll pallets and the need for space for the storage and prompt clearance of empty cartons.

As the Buntingford depot becomes fully operational the vehicle fleet is to be expanded

and by next March, on the completion of the refrigerated section of the depot, Mr. Horn expects to be operating between 70 and 80 vehicles and the ultimate fleet may be 90. This number will include over 40 attics. Some hiring will be necessary to clear peak loads.

The whole emphasis of the Sainsbury distribution philosophy is on rapid turnover of stocks with the greatest possible speed of delivery of fresh produce to the 250 shops. These, incidentally, are in the southern half of the country, with the most northerly shop at Nottingham and most westerly at Bristol. I shall be somewhat surprised if the northern counties are not invaded before long!

The butler stocks needed for the assembly of shop orders are turned over so rapidly that it is hardly an exaggeration to say the stock holding maintained bridges the gap between "now" and the next delivery rounds. The point is worth making strongly, for the casual visitor observing the large volume of palletized goods on the 4-tier racking might not appreciate the rapid throughput of stocks at the depot.

Stock holdings at Sainsbury shops are largely maintained on the imprest principle, stock levels being replenished as frequently as proves necessary. A computer at the Blackfriars office processes sales data received from shops and the transport department at Buntingford knows on Thursday the requirements for delivery on Monday, Tuesday and Wednesday of the week following. It is difficult precisely to forecast sales for the weekend shopping days and managers may adjust orders for highly perishable foods for delivery on Thursday and Friday. A large shop, Mr. Horn told me, absorbs 6or 7-vehicle loads a day and a supplementary order of perishable foods could necessitate an additional vehicle journey—which might be uneconomic—or the hasty removal of nonperishable goods to make room in the vehicle. The comptiterized ordering system is flexible enough for pre-planned orders to be stopped and rearranged before the make-up stage.

There are, in effect, some 2,000 different commodities—Sainsbury has several hundred of its own brands—at Buntingford for different sized packs need to be segregated even if contents are identical. By the same token bonus offers—very common today—must be dealt with carefully to meet the sales dates specified. Depot aisles and racking are identified numerically and the system of recording shop orders on debit notes for make up in the depot seemed logical and as foolproof as any such system can be. I gather that inaccuracies in the making-up are very rare.

The pallet trucks used carry a removable adapter to carry two of the standard roll pallets used for shop deliveries. After unloading on their return to the depot they are given a cursory inspection and any unserviceable ones are segregated for repair or maintenance.

The Sainsbury fleet of Leyland-engined Bedford vans, mainly of 7 tons carrying capacity, is well fitted out with quick release load retaining devices and floor chocks. A well-equipped maintenance and repair shop deals with all but major jobs and the familiar livery is maintained by a modern vehicle washing plant.

In the space remaining it seems appro

priate to deal with personnel aspects in the widest sense. At the operative level Sainsbury has anticipated the mooted establishment of a training board for the retail trade and all grades undergo an induction and training course appropriate to their jobs. Fitters, for example, are sent on diesel engine maintenance and refrigeration engineering courses. Two transport supervisers, both ex-drivers—spend much of their time visiting shops to observe vehicle turn-round arrangements—an excellent idea which deserves to be widely followed.

Management development

An intensive management development programme is also well-established. From what I saw of the depot organizational routines it has already borne fruit. It is evident, too, that the central work study department has given detailed consideration to the efficient layout, lighting and heating of the premises. Much could be written of the inunaculate cleanliness of the premises— floor and wall surfaces have been specially chosen for ease of cleaning. The white uniformed staff would not be out of place in a pathology laboratory!

It is a pleasure to write of a E4 million project that reflects the bold thinking of the Sainsbury directors and management. For so long road transport, warehousing and distribution have not attracted the capital needed for their most productive employment. The Sainsbury Buntingford distribution depot will, I think, handsomely repay the hard cash and hard thinking that has gone into its design. May many other comparable organizations try to emulate their example.