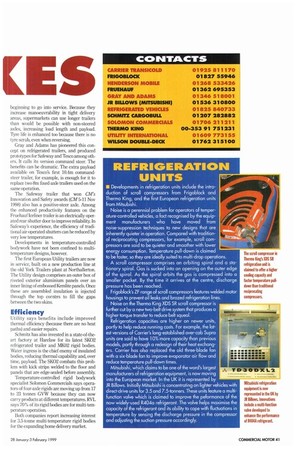

C01:01. 130

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

Productivity is the name of the game in temperaturecontrolled transport. To meet this need manufacturers have developed a range of flexible trailers that can carry multi-temperature goods and perform better in the delivery yard. Sharon Clancy reports on the latest products in the cold wars.

Multi-temperature bodies, doubledeck trailers and steering axles are among the latest weapons in the drive to increase productivity on temperature-controlled transport operations.

Supermarket chains and food wholesalers have been leading the way, seeking to drive down their delivery costs and reduce empty running. But multi-compartment, multi-temperature bodies also suit hauliers specialising in temperature-control bemuse the internal layout can be adjusted to suit return loads and a range of contracts.

Multi-temperature operations have become possible with the development of refrigeration systems with remote evaporators (so called bemuse they are separate from the condenser unit and power unit). Each compartment in the body can have its own evaporator, able to heat as well as cool air, and its own temperature-control unit.

Rigids traditionally relied on bulkhead fans to push cool air to the rear compartment, so colder foods had to be carried in the front. Multi-temperature trailers were even rarer, because it was difficult enough to cool the back of the trailer efficiently in the first place, without a bulkhead to cope with.

Equally impressive are the productivity gains from double-deck trailers, which provide up to 70% more cargo area than a conventional semi-trailer. Temperature-controlled double-deckers tend to be bespoke because of the need to take account of specific operational patterns, loading and unloading methods and the height of containers.

The step-frame double-deck design pioneered by Wilson l)ouble-Deck Trailers in Northern Ireland helped maximise interior height by lowering the floor between the wheelarches. But the absence of a maximum height limit in the UK and Northern Ireland has strengthened the appeal of doubledeckers based on conventional straight-frame trailers.

Moveable internal bulkheads mean compartments can be configured to suit each day's delivery needs. The supermarket chains have adopted double-deckers in a big way to serve their Northern Ireland operations. Using fewer vehicles on this work doesn't only save fuel, it cuts ferry charges, which are based on vehicle length. Each deck can have one or more evaporators, while moveable bulkheads allow the compartment configuration to be adjusted to suit operational requirements.

Flexibility

The aluminium-bar systems from Henderson Mobile and Schmitz's are the simplest route to double-decking They offer flexibility in deck height, but can extend loading times. Lifting second decks substantially cut loading times but the extra weight and difficulty in ensuring proper temperature seals has led to a trend towards fixed upper decks, sometimes with internally mounted rear tail-lifts, sometimes with an external lift.

Refrigerated trailers with steering axles are beginning to go into service. Because they increase manoeuvrability in tight delivery areas, supermarkets can use longer trailers than would be possible with non-steered axles, increasing load length and payload. Tyre life is enhanced too because there is no tyre scrub, even when reversing.

Gray and Adams has pioneered this concept on refrigerated trailers, and produced prototypes for Safeway and Tesoa among others. It calls its version command steer. The benefits can be dramatic. The extra payload available on Tesco's first 10.4m commandsteer trailer, for example, is enough for it to replace two 8m fixed-axle trailers used on the same operation.

The Safeway trailer that won CM'S Innovation and Safety awards (CM 5-11 Nov 1998) also has a positive-steer axle. Among the enhanced productivity features on the Fruehauf recliner trailer is an electrically operated rear shutter door to improve reliability In Safeway's experience, the efficiency of traditional air-operated shutters can be reduced by very low temperatures.

Developments in temperature-controlled bodywork have not been confined to multitemperature designs, however.

The first European Utility trailers are now in service, built on a new production line at the old York Trailers plant at Northallerton. The Utility design comprises an outer box of riveted exterior aluminium panels over an inner lining of embossed Kemlite panels. Once these are assembled insulation is injected through the top cormrs to fill the gaps between the two skins,

Efficiency

Utility says benefits include improved thermal efficiency (because there are no heat paths) and easier repairs.

Schmitz has also invested in a state-of-theart factory at Harelaw for its latest SK02 refrigerated trailer and MR/2 rigid bodies. Water ingress is the chief enemy of insulated bodies, reducing thermal capability and, over time, payload. The SK02 combats this problem with kick strips welded to the floor and panels that are edge-sealed before assembly.

Temperature-controlled rigid bodywork specialist Solomon Commercials says operators of four-axle rigids are moving up from 17 to 23 tonnes GVW because they can now carry products at different temperatures. RVL says 700/o of its rigid bodies are for multi-temperature operation.

Both companies report increasing interest for 3.5-tonne multi-temperature rigid bodies for the expanding home delivery market