• iJfJeIifle Jj When Sweden's national railway com

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

• iJfJeIifle Jj When Sweden's national railway company wanted to test natural gas in its road fleet, New was happy to oblige. Six months into the trial CM has driven the truck and talked to the man in charge.

the • The Swedes take their environment seriously. Money is made available to fund research into Green vehicles and in 1988 the Swedish Parliament approved a SKr9Om (£8.5m) grant to the Swedish Transport Research Board (STB) for a series of freight and passenger transport trials.

These included a trial of 32 methanolpowered Scania city buses in Stockholm and 20 compressed natural gas (CNG) Volvo buses in Gothenburg. Buses have been given a high priority as they tend to operate in the inner cities, but Svelast, the road transport division of Swedish Railways (SJ), faces similar problems to the bus operators. Its trucks carry ISO containers and other freight from the railheads, around which most major Swedish towns are built and the company is looking for a cleaner alternative to diesel.

DRIVING FORCE Stig Larsson, president and director-general of SJ, is the driving force behind the company's dash to gas. "This is an image question," he says. "The train is friendly to the environment. There is no direct payback for us, but there is an indirect one. If we have a better image we can attract more business and gain a benefit from carrying more customers. Compared to our investment the payback could be very large indeed."

Not surprisingly Volvo and Scania were invited to take part in the trials, but they were unable to supply suitable vehicles. Iveco, with its Swiss engine research centre Iveco Motoren Forschung (formerly Dereco), duly came up with a 240.26 long-wheelbase tagaxle tractor powered by the 8469.41 natural gas engine.

SJ's investment to date totals Skr2.66m (251,500). The Government has promised Skr945,000 (£89,400), of which half has so far been paid.

Svelast operates more than 350 diesel trucks and Larsson plans to convert the entire fleet to CNG as soon as the technology, and refuelling stations are in place. That will take major investment, not least from the fuel companies who must establish the infrastructure in a country without natural gas supplies.

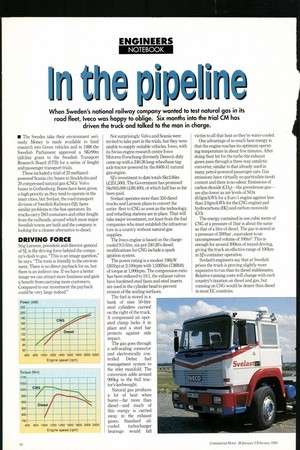

The Iveco engine is based on the chargecooled 9.5-litre, six-pot 240.26's diesel: modifications for CNG include a spark ignition system.

The power rating is a modest 198kW (265hp) at 2,100rpm with 1,026Nm (7381bft) of torque at 1,000rpm. The compression ratio has been reduced to 10:1, the exhaust valves have hardened steel faces and steel inserts are used in the cylinder head to prevent erosion of the sealing surfaces.

The fuel is stored in a bank of nine 50-litre steel cylinders carried on the right of the truck. A compressed air operated clamp locks it in place and a steel bar protects against side impact.

The gas goes through a self-sealing connector and electronically controlled Deltec fuel management system to the inlet manifold. The conversion adds around 900kg to the 6x2 tractor's kerbweight.

Natural gas produces a lot of heat when burnt—far more than diesel—and much of this energy is carried away in the exhaust gases. Standard oilcooled turbocharger bearings would fall victim to all that heat so they're water-cooled.

One advantage of so much heat energy is that the engine reaches its optimum operating temperature in about five minutes. After doing their bit for the turbo the exhaust gases pass through a three-way catalytic converter, similar to that already used in many petrol-powered passenger cars. Gas emissions have virtually no particulate (soot) content and there is no odour. Emissions of carbon dioxide (COO—the greenhouse gas— are also lower as are levels of NOx (8.0gm/kWh for a Euro 1 engine against less than 2.0gm/kWh for the CNG engine) and hydrocarbons (HC) and carbon monoxide (CO).

The energy contained in one cubic metre of CNG at a pressure of lbar is about the same as that of a litre of diesel. The gas is stored at a pressure of 200bar, , equivalent to an uncompressed volume of 100m3. This is enough for around 300km of mixed driving, giving the truck an effective range of 100km in SJ's container operation.

Svelast's engineers say that at Swedish prices the truck is proving slightly more expensive to run than its diesel stablemates. Relative running costs will change with each country's taxation on diesel and gas, but running on CNG would be dearer than diesel in most EC countries.

r Coolant L sensor For now refuelling involves changing the cassette. This requires a forklift truck and takes 20 minutes. The cassettes are recharged a Sweden's only natural gas supply point, near Malmo, and the project is only practicable because SJ has the trains to carry the cassettes back and forth. In operation CNG tucks would refuel at recharge stations by plugging in a fuel pipe. This should take less than 20 minutes.

When it comes to maintenance there are few differences from the standard diesel engine. Special mineral lubricants are used to withstand the high temperatures, but the rest of the engine is unaffected.

IMPRESSIONS Once in the cab the only clue to the change of fuel is a small LED display on top of the dashboard. As the key is turned 12 small lights come on one from left to right, indicating that the CNG cassette is fully charged.

The engine shudders into life just like any diesel but idles as quietly as a large van. We were loaded to 26 tonnes and pulled away comfortably in secld gear.

In the cold conditi ns plumes of harmless steam come from the exhaust, but the engine warms up fast to get the cab up to a comfortable temperature Once on the auto-route the CNG truck drives very much like any mediumpowered tractor, but its power comes in much more smoothly than a diesel and in-cab noise is almost as low as your average car. It is like driving a petrol engine, except that there is plenty of engine braking available through the exhaust brake despite the low (10:1) compression ratio.

The engine is uncannily smooth, producing no perceptible vibration. Lugging down to 800rpm the CNG engine is slow to recover as peak torque is not on tap until the 1,400rpm mark, but noise levels remain low with no visible exhaust.

Our test route took in 135km of mixed roads with the lights of the fuel gauge going out one by one.

By the time we returned to SJ three hours later only six lights remained. The problem of fuel storage has yet to be overcome.

The CNG engine has not been officially launched, but Iveco says it is commercially available, and larger customers prepared to pay for the modifications will receive the necessary back-up. It's early days yet, but with the right infrastructure this environmentally friendly technology must have a bright future.

by Danny Coughlan