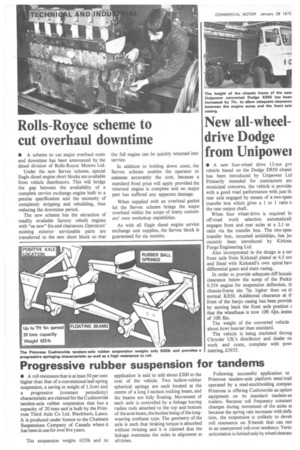

Progressive rubber suspension for tandems

Page 26

If you've noticed an error in this article please click here to report it so we can fix it.

fb A roll resistance that is at least 50 per cent higher than that of a conventional leaf-spring suspension, a saving in weight of 1.5cwt and a progressive (constant periodicity) characteristic are claimed for the Cushionride tandem-axle rubber suspension that has a capacity of 20 tons and is built by the Primrose Third Axle Co Ltd, Blackburn, Lancs. It is produced under licence to the Chalmers Suspensions Company of Canada where it has been in use for over five years. application is said to add about £200 to the cost of the vehicle. Two hollow-rubber spherical springs are each located at the centre of a long 1-section rocking beam, and the beams are fully floating. Movement of each axle is controlled by a linkage having radius rods attached to the top and bottom of the axle beam, the bushes being of the longwearing urethane type. The geometry of the axle is such that braking torque is absorbed without twisting and it is claimed that the linkage maintains the axles in alignment at all times. Following successful application to Primrose tandem-axle platform semi-trail operated by a steel-stockholding compan Primrose is offering Cushionride as option equipment on its standard tandem-ax trailers. Because roll frequency constant changes during movement of the axles ai because the spring rate increases with defle tion, the suspension is unlikely to devel( roll resonance on S-bends that can resi in an unexpected roll-over tendency. Verde articulation is limited only by wheel clearam