Simple Ways of Improving Diesel Combustion

Page 55

If you've noticed an error in this article please click here to report it so we can fix it.

NEW RUSSIAN APPROACH TO PILOT INJECTION: SYSTEM THAT DISPENSES WITH THE PUMP

TN a conversation some years ago with Harry Weslake, regarding a new variablecompression-ratio piston in which I was interested, Mr. Weslake proffered some very sound advice. "When considering the potential of a patent", he observed, "I always ask myself the question, will it add to the production cost of the engine by more than a few pence? If so, I generally forget about it."

The first impression of studying the Motor Industry Research Association's monthly summaries of automobile engineering literature covering the past 18 months or so is that progress in engine research is inescapably associated with relatively complex mechanisms (such as the use of variablecompression-ratio pistons and compounding a diesel with a turbine). But in a number of cases research relates to a simple modification of an established system or to a simplified system that could offer substantial benefits, possibly at a lower cost.

In citing the first example, a modified diesel injector pump evolved in Russia, I am reminded of a comment by P. WindsorSmith, chief engineer of the Daimler company, regretting that no progress had been made with pilot injection which could, in his opinion, foster the use of smaller diesels in competition with petrol engines by providing smoother operation even if fuel consumption were somewhat increased.

In a description of a diesel injection pump giving a "staged" injection characteristic in Avtomobilnaya Promishlennost B. N. F ainleib emphasizes that the elimination of combustion harshness by controlling the rate of pressure rise during the initial phase of combustion can reduce engine stresses and wear very substantially, the bugbear of shock pressures being resonance-incited stresses and deformations of the working parts.

From this it can be assumed that staged injection could enable the use of lighter and cheaper engine structures. The system is claimed to "maintain an adequate fuel consumption".

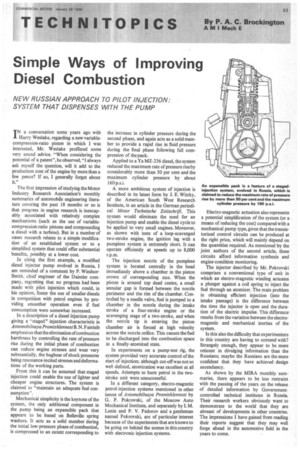

Mechanical simplicity is the keynote of the system, the only additional component in the pump being an expansible pack that appears to be based, on Belleville spring washers. It acts as a solid member durinf the initial low-pressure phase of combustion, is compressed to an extent corresponding to the increase in cylinder pressure during the second phase, and again acts as a solid member to provide a rapid rise in fluid pressure during the final phase following full compression of the pack.

Applied to a Ya MZ-236 diesel, the system reduced the maximum rate of pressure rise by considerably more than 50 per cent and the maximum cylinder pressure by about 160 p.s.i.

A more ambitious system of injection is described in its latest form by J. E. Witzky, of the American South West Research Institute, in an article in the German periodical Motor Technische Zeitschrjfl. This system would eliminate the need for an injection pump and enable the diesel cycle to be applied to very small engines. Moreover, as shown with tests of a loop-scavenged two-stroke engine, the ignition lag with a pumpless system is extremely short It can operate efficiently at speeds up to 8,000 r.p.m.

The injection nozzle of the pumpless system is located centrally in the head immediately above a chamber in the piston crown of corresponding size. When the piston is around top dead centre, a small annular gap is formed between the nozzle perimeter and the rim of the chamber. Controlled by a needle valve, fuel is pumped to a chamber in the nozzle during the intake stroke of a four-stroke engine or the scavenging stage of a two-stroke, and when the nozzle tip is entering the piston chamber air is forced at high velocity across the nozzle orifice. This causes the fuel to be discharged into the combustion space in a finally-atomized state.

In experiments on a pump-test rig, the system provided very accurate control of the start of injection; although cut-off was not so well defined, atomization was excellent at all speeds. Attempts to burn petrol in the twostroke unit were unsuccessful.

In a different category, electro-magnetic petrol-injection systems mentioned in other issues of Avtomobilnaya Promishlennost by G. P. Pokrovski, of the Moscow Auto Mechanical Institute, and separately by I. M. Lenin and P. V. Fedorov and a gentleman named Pokrovski, are of particular interest because of the experiments that are known to be going on behind the scenes in this country with electronic injection systems.

Electro-magnetic actuation also represents a potential simplification of the system (or a means of reducing the cost) compared with a mechanical pump type, given that the transistorized control circuits can be produced at the right price, which will mainly depend on the quantities required. As mentioned by the joint authors of the second article, these circuits afford information synthesis and engine-condition monitoring.

The injector described by Mr. Pokrovski comprises a conventional type of unit in which an electro-magnetic winding actuates a plunger against a coil spring to inject the fuel through an atomizer. The main problem in obtaining efficient injection (into the intake passage) is the difference between the time the injector is open and the duration of the electric impulse. This difference results from the variation between the electromagnetic and mechanical inertias of the system.

Is this also the difficulty that experimenters in this country are having to contend with? Strangely enough, they appear to be more reticent in divulging information than the Russians; maybe the Russians are the more confident that they have achieved design ascendancy.

As shown by the MIRA monthly summaries, there appears to be less restraint with the passing of the years on the release of detailed information by Governmentcontrolled technical institutes in Russia. Their research workers obviously want to demonstrate to the world that they are abreast of developments in other countries. The impressions I have gained from reading their reports suggest that they may well forge ahead in the automotive field in the years to come.