Converting to Oil Without a Kit

Page 36

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

Non-standard Conversions are Not to be Feared

by John Savage,

A.I.R.T.E.

SOUND .engineering practice, common sense and ingenuity form the three main requisites when installing oil engines in vehicles for 'which no conversion kits are availably.

This was the conclusion I reached after a recent visit to Kays (Derby), Ltd., Derby, to determine what facilities were necessary to carry out what I. may call non-standard conversions. Iexamined the merits of converting to oil in an article in The Commercial Motor on September 17. 1954.

A claim made by Kays is that they can fit an oil engine into any chassis,' whether a kit be available or not. They do not use any special equipment and only a few drawings and Mates are made. The fitters employed are, of course, skilled, and they have now acquired considerable experience in this class of work.

The conversions that I saw at Derby, both at Kays and in the hands of local operators, convinced me that the advantages of converting to oil should not be missed merely because a standard kit is not available for a particular make or type of vehicle I discussed the problems that are often encountered, and learnt how Kays have overcome them. There is no doubt that it is the practical approach to the work that enables such conversions to be successfully carried out. .

The choice of the new engine must be made with some thought as-to size and output, but provided that the unit matches the petrol engine to within reasonable limits, it should be suitable. _ ..

Since 1938, when Kays carried out ,

their. first conversion in a Dodge chassis, • non-standard conversions have been tackled . on : Canadian Fords, Chevrolet andDodge truCks, American G.M.C., International 'K7s and K8s and Jeeps. Crossley, Thornycroft, Morris-Commercial,

Dennis, Albion, Land-Rover, Wolseley and Humber are among other vehicles which have been successfully converted although no kits are available for any of them.

All the conversions have been successful, and most have been completed in from seven to 10 days, although some of them have proved a little tricky.

The worst job that the service manager, Mr. Patrick Ferguson, could recall was two B.R.S. Albion short-wheelbase tippers with Leyland gearboxes. The combination of an Albion vehicle, a Leyland gearbox, a Perkins P.6 engine and a completely fabricated clutch housing tried the ,fitters' patience when it came to putting them all together.

Fabricated Clutch Housings The practice adopted by Kays, when possible, is to fit the clutch and gearbox to the new engine while it stands on the shop floor. This usually involves fabricating a clutch bell-housing and making some changes to the clutch centreor pressure-plates. In this matter the manufacturers of the clutches are usually consulted. • The engine and gearbox assembly then suspended in position over the chassis, and brackets for carrying the engine mountings are made to suit. To facilitate this operation Kays use two mobile cranes. They are not essential, but as four or five conversions are carried out at once, on some occasions, they find them a great asset.

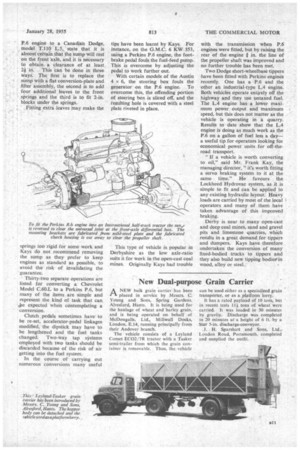

Sometimes it is not convenient to remove the gearbox, as was the case with an International half-track tractor that was coMpleted during my, visit. In such cases, the engine is offered up to the .gearbox and, a bell-housing is fabricated to fill the gap.

To carry out 'unusual conversions, Kays have never failed to make use of parts from conversion kits for other vehicles. 'A simple example of this is the Canadian Ford water pipe. The choice of a vertical corrugated hose to the header tank looks obvious, but Kays have found that, in practice, this is not successful, so the backswept hose and elbow for a Dodge conversion are used.

One of the conversions using the most parts . from kits for other vehicles was a Bedford 7-ton tractor unit which is believed to be the first Bedford conversion using an R.6 engine ever undertaken. A complete kit can now be obtained, but at the time the only part available was the clutch bell-housing.

A bare Perkins R.6 engine was used, with a Dodge Perkins R.6 starter ring-gear, clutch pressureplate and centre-plale disc. A Bedford centre-plate ,hub and a fabricated back-plate completed the assembly.

The clutch cross-shaft and operating fork were modified to suit, and the front cross-member of the chassis was lowered an inch.

The directions for fitting. a Perkins

P.6 engine to a Canadian Dodge, model T.110 L.5, state that it is almost certain that the sump will rest on the front axle, and it is necessary to obtain a clearance of at least 21 in. This can be done in three ways. The• first is to replace the sump with a flat conversion-plate and filter assembly, the second is to add four additional leaves to the front springs and the third is to fit 2-in. blocks under the springs.

Fitting extra leaves may make the springs too rigid for some work and Kays do not recommend removing the sump as they prefer to keep engines as standard as possible, to avoid the risk of invalidating the guarantee.

Thirty-two separate operations are listed for converting a Chevrolet Model C.60.L to a Perkins P.6, but many of the items are simple and represent the kind of task that can e expected when contemplating a conversion.

Clutch pedals sometimes have to be re-set, accelerator-pedal linkages modified, the dipstick may have to be lengthened and the fuel tanks changed. Two-way tap systems employed with two tanks should be discarded because of the risk of air getting into the fuel system.

In the course of carrying out numerous conversions many useful tips have been learnt by Kays. For instance, on the G.M.C. 6 KW 353, using a Perkins P.6 engine, the footbrake pedal fouls the fuel-feed pump. This is overcome by adjusting the pedal to work further out.

With certain models of the Austin 4 x 6, the steering box fouls the generator on the P.6 engine. To overcome this, the offending portion of steering box is sliced off, and the resulting hole is covered with a steel plate riveted in place.

This type of vehicle is popular in Derbyshire as the low axle-ratio suits it for work in the open-cast coal mines. Originally Kays had trouble with the transmission when P.6 engines were fitted, but by raising the rear of the engine J in. the line of the propeller shaft was improved and no further trouble has been met.

Two Dodge short-wheelbase tippers have been fitted with Perkins engines recently. One has a P.6 and the other an industrial-type L.4 engine. Both vehicles operate entirely off the highway and they use untaxed fuel. The L.4 engine has a lower maximum power output and maximum speed, but this does not matter as the vehicle is operating in a quarry. Results to date show that the L.4 engine is doing as much work as the P.6 on a gallon of fuel less a day— a useful tip for operators looking for economical power units for off-theroad transport.

"If a vehicle is worth converting to oil," said Mr. Frank Kay, the managing director, "it's worth fitting a servo braking system to it at the same time." He favours the Lockheed Hydrovac system, as it is simple to fit and can be applied to any existing hydraulic layout Heavy loads are carried by most of the local operators and many of them have taken advantage of this improved braking.

Derby is near to many open-cast and deep coal mines, sand and gravel pits and limestone quarries, which results in a great demand for tippers and dumpers. Kays have therefore undertaken the conversion of many fixed-bodied trucks to tippers and they also build new tipping bodies in wood, alloy or steel.