The New 50-cwt. Albion.

Page 8

Page 9

If you've noticed an error in this article please click here to report it so we can fix it.

A Chassis Which Has Now Been Placed on the Market After 18 Months Testing.

In view of the very peculiar and unique state of the commercialvehicle market, owing to the practical absence of vehicles with a capacity for loads of over two tons, it is with feelings approaching almost to relief that one takes advantage of such an opportunity as the present one, the occasion being the exam. ination of the design and details cf a 30-cwt. chassis of such distinction as can be expected from the Albion Motor Car Co., Ltd. This machine. although only now about to be placed on the open market, has been for some 18 months under test.

In this particular model, the lines follow very closely ordinary and standard Albion practice, particularly the 25 h.p. two-ton model which was dealt with in the "Care of the Chassis" series in our issue of the 9th July, 1914. The principal difference, of course, is that whereas the two-tormer is chaindriven, the model under review has a propeller shaft and bevels as a transmission.

Well-designed Control.

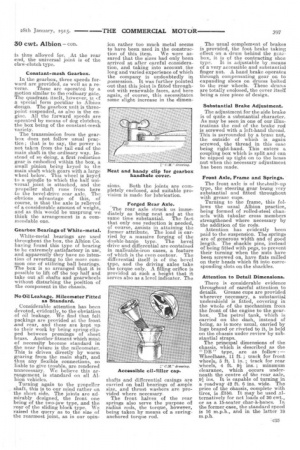

Taking the component parts in order, and commencing with the engine, this is a four-cylinder 20 h.p., 3 in. by 51 in. bore and stroke, respectively, and is governed to a normal speed of 1050 r.p.m., with the throttle fully open. It follows almost exactly the standard practice of the Albion Co., one of the outstanding features of which is the excellent lubrication system, in which a gear pump is employed, drawing the oil through an extra large filter, which is placed in the sump, and forcing it to all the crankshaft bearings, including those for the connecting-rod big-ends. The Bump is filled through an accessible orifice on the crankcase arm. The valve gear is enclosed by an easilydetachable cover, adjustable tappets are provided, and we noted that a particularly large bearing

surface was provided for them. Several of the parts of the engine are the subject of patents, and we might refer to the fan and pump, which are combined on one spindle, the pump being situated inside the jacket of the foremost cylinder. The Murray patent governor is placed in a case inside the engine, and operates in conjunction with the hand control on the steering column to set the opening of the throttle valve. An excellent feature of this combined control is that, for any particular setting of the hand lever, a corresponding definite engine speed is obtained. This holds good no matter whether the engine is running light or engaged on what might he termed collar work.

The carburetter itself is also an Albion patent, the outstanding feature beine a mechanically-operated pilot valve. This is so arranged that, on commencing to open, a very rich mixture is fed to the engine, and diluted and correctly proportioned as the throttle opening is increased. The ignition is taken care of by the usual Bosch magneto. From the engine the power is transmitted to a plate clutch. This consists of a soft steel ring between two others of Ferode, and these are brought into engagement by means of half-a-dozen springs in pockets attached to the flywheel casing. The clutch shaft is provided with two universal icints, one of which is of peculiar construction and is contained within the body of the clutch. The forward end of the clutch shaft is hollow, and bears on the spherical end of the pivot bush. To the end of the shaft is fastened a gearwheel which meshes with an internal gear, which again is driven

by the clutch plate. Any slight non-alignment of the clutch shaft

is thus allowed ior. At the rear end, the universal joint is of the claw-clutch type.

Constant-mesh Gearbox.

In the gearbox three speeds forward are provided, as well as a reverse. These are operated by a motion similar to the oactinary gate. The quadrant itself, however, is ef a special form peculiar to Albion design. The gearbox unit is threepoint suspended, as also is the engine. All the forward speeds are operated by means of dog clutches, the box being of the constant-mesh variety.

The transmission from the gearbox does not follow usual practice ; that is to say, the power is not taken from the tail end of the main shaft in the ordinary way. instead of so doing, a first reduction gear is embodied within the box, a small pinion being keyed to the main shaft which gears with a large wheel below. This wheel is keyed

to a spindle to which the half universal joint is attached, and the

propeller shaft runs from here to the bevel-drive rear axle. The obvious advantage of this, of course, is that the axle is relieved of a considerable amount of weight, and as this would be unsprung we think the arrangement is a commendable one.

Gearbox Bearings of White-metal.

White-metal bearings are used throughout the box, the Albion Co. having found this type of bearing to be extremely satisfactory in use, and apparently they have no intention of reverting to the more common one of utilizing ball bearings. The box is so arranged that it is possible to lift off the top half and take out all shafts and gearwheels without disturbing the position of the component in the chassis.

No Oil Leakage. Mileometer Fitted as Standard.

Considerable attention has been devoted, evidently, to the obviation of oil leakage. We find that felt packings are provided at the front and rear, and these are kept up to their work by being spring-clipped between pressings of sheet brass. Another fitment which muse of necessity become standard in the near future is the mileometer. This is driven directly by worm gearing from the main shaft, and thus any flexible connections, so liable to give trouble, are rendered unnecessary. We believe this arrangement is standard on all Albion vehicles.

Turning again to the propeller shaft, this is to our mind rather on the short side. The joints are admirably designed, the front one being of the two-jaw type, and the rear of the sliding block type. We raised the query as to the size of the rearmost joint, as in our opin

ion rather too much metal seems to have been used in the construction of this item. We were assured that the sizes had only been arrived at after careful consideration, and taking into account the long and varied experience of which the company is undoubtedly in possession. It was further pointed out that this joint is fitted throughout with renewable faces, and here again, of course, this necessitates some slight increase in the dimen sions. Both the joints are com pletely enclosed, and suitable provision is made for lubrication.

Forged Rear Axle.

The rear axle struck us immediately as being neat and at the same time substantial. The fact that only one reduction is needed, of course, assists in attaining the former attribute. The load is carried by a massive forging of the double-banjo type. The bevel drive and differential are contained an malleable-iron cases, a feature of which is the even contour. The differential itself is of the bevel type, and the driving axles take the torque only. A filling orifice is provided at such a height that it serves also as a level indicator. The shafts and differential casings are carried on ball bearings of ample size, and thrust washers are provided where necessary.

The front halves of the rear springs also serve the purpose of radius rods, the torque, however, being taken by means of a springanchored torque rod. The usual complement of brakes is provided, the foot brake taking effect on a drum behind the gearbox, it is of the contracting shoe type. It is adjustable by ,means of a very accessible and substantial finger nut. A hand brake operates through compensating gear on to expanding shoes on drums bolted to the rear wheels. These drums are totally enclosed, the cover itself being a nice piece of design.

Substantial Brake Adjustment.

The adjustment for the side brake is of quite a substantial character. As may be seen in one of our illustratioes the end of the brake rod is screwed with a left-hand thread. This is surrounded by a brass nut, the outside of which is again screwed, the thread in this case being right-hand. This enters a coupling box which is split and can be nipped up tight on to the brass nut when the necessary adjustment has been made.

Front Axle, Frame and Springs.

The front axle is of theAanilt-up type, the steering gear being very substantial and fitted throughout with grease cape. Turning to the frame, this follows the usual Albion practice, being formed of rolled-steel channels with tubular cross members strengthened where necessary by the addition of tie rods.

Attention has evidently been paid to the suspension. The springs are of generous width and of good length. The shackle pins, instead of being fitted with pegs, to prevent their turning when the nuts have been screwed on, have flats milled on their heads which fit into corresponding slots on the shackles.

Attention to Detail Dimensions.

There is considerable evidence throughout of careful attention to details. Grease cups are provided wherever necessary, a substantial underehield is fitted, covering in the whole of the mechanism from the front of the engine to the gearbox. The petrol tank2 which is carried on the dash, instead of being, as is more usual, carried by lugs brazed or riveted to it, is held on the chassis under review by substantial straps. The principal dimensions of the chassis, which is described as the " DB " type, are as follow:-Wheelbase , 11 ft. ; track for front wheels, 5 ft. 1 in. ; track for rear wheels, 4 ft. 9i ins. ; minimum clearance, which OCCUTs underneath the centre of the rear axle, .91 ins. It is capable of turning in a roadway 42 ft. 6 ins. wide. The price of the chassis, complete with tires, is £51.0. It may be used alternatively for net loads of 30 cwt., or as a 15-seater char-h-bancs.

the former case, the standard speed is 16 m.p.h., and in the latter 18 m.p.h.