FUEL-SAVER fo 5-cwt. Loads

Page 38

Page 39

Page 40

If you've noticed an error in this article please click here to report it so we can fix it.

AUSEFUL payload capacity, distinctive appearance, good suspension and braking and low fuel consumption characterize the new Bedford oil-engined 35-cwt. van. The 35-cwt. chassis, which is available with 76-b.h.p. petrol engine or Perkins P.4 oil engine, was introduced last September and, in conjunction with a 25-cwt. model, replaces the former 25-30-cwt. chassis.

It is available as a chassis or as a chassis with cab in pick-up form and as a 300-cu.-ft. van with Spurling allmetal body. The oil-engined van, which I tested, has a basic, price of £923, purchase tax adding a further £156 5s. 5d.

Heavier Springs and Tyres The -general specification of the 35-cwt. chassis is similar to that of the earlier 25-30-cwt. model, except that heavier rear springs and 8.25-16-in. (10-ply) tyres are fitted. The larger tyres increase the turning circle from 46 ft. to 48 ft.

The engine is mounted as a unit at three points with the four-speed gearbox, which has synchromesh engagement on top, third and second ratios. I found that gear-changing was faultless at all times; clutchless changes were made as a matter of course.

A two-piece propeller shaft with Hardy Spicer needle-roller universal joints and a single-row, sealed-ballbearing rubber-mounted centre bearing, takes the drive to the semi-floating spiral-bevel rear axle. This has a reduction ratio of 4.714 to 1.

Simple Layout A simple frame layout is employed, consisting of pressed-steel channelsection side members with five crossmembers riveted by "cold-squeeze." The side members are swept up

slightly over the rear axle. The springs at both axles are 45 in. long and work in conjunction with double-acting piston-type dampers to give a smooth ride under varying conditions of load over good or bad surfaces.

Bedford brakes are well known for their efficiency and those fitted to the van are no exception. A straight hydraulic system, without assistance, is employed and leading-and-trailingshoe wheel units are fitted. A tandem master-cylinder ensures that should the brakes of either axle fail, those on the two other wheels would still be effective.

The Spurling van body has steel cross-bearers and six rubber mountaet

ings. The wide, curved, two-piece windscreen gives a good range of forward vision, but in wet weather the arc cleaned by the windscreen wipers is too small and visibility suffers.

Sliding doors give entry to the cab from each side and to the front of the load compartment. At the rear there are wide folding doors which can be clipped back to lie flush with the body sides.

Only one driving mirror is fitted as standard, but a near-side mirror can be obtained as an optional extra. Other extras include a two-man passenger seat, partitions behind the driver, interior lashing rails, roof extractor ventilator and either a halfdepth roller shutter and tailboard or a full-depth shutter. .

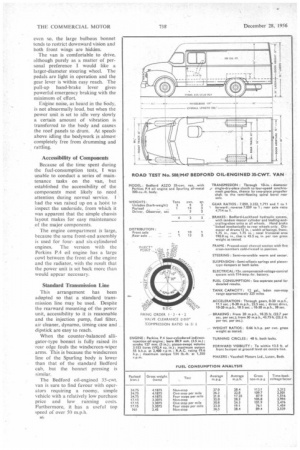

The body weighs just over 101 cwt. and the kerb weight of the test vehicle was 2 tons 51 cwt. A test load of 34f cwt. was added, and complete with driver and myself aboard, the van scaled 4 tons 31 cwt.

The first test was made up Bison Hill, which is three-quarters of a mile long and has an average gradient of 1 in 10f. At the bottom, the water temperature was 146° F., ambient being 40° F. The hill was climbed in 3 minutes 12 seconds, and the lowest gear used was second, which was engaged for 1 minute 25 seconds. During the climb the coolant temperature rose by only 14° F.

A descent was then made in neutral with the foot brake applied to restrict the speed to 20 m.p.h.

Halfway down the hill, where the gradient slackened, I engaged top gear and used full throttle against the brakes in an attempt to induce brake fade by artificial means, but at the bottom a " crash " stop from 29 m.p.h. produced a Tapley meter reading of 71.5 per cent.

Pedal travel had increased by 1,1 in. There was a pronounced smell of hot brake facings, but the drums were not smoking and, as subsequent tests showed, the braking efficiency had been reduced by approximately only 20 per cent.

Easy Sind on 1 in 4.7

The van was then taken to a hill in Berkhamsted, where there is a maximum gradient of 1 in 4.7. The vehicle was stopped on this gradient and the hand brake held it with perfect safety and without undue effort on the lever. A smooth low-gear restart was made, and this was repeated several times without recourse to excessive clutch slipping.

An optimistic attempt at starting in second gear failed, as might be expected, but the .low-gear performance indicated that there was plenty of power in hand for gradients of up to 1 in 3.5.

Braking tests produced excellent stopping distances from 20 m.p.h.

and 30 m.p.h. Only slight wheellocking was noticed during any of the tests and, as with all straight hydraulic systems, there was no noticeable delay. The maximum deceleration in each case as shown

by the Tapley meter was 20 per cent higher than the average deceleration indicated by the stopping distances.

When the hand brake was applied from 20 m.p.h., both rear wheels locked instantly and the average Tapley meter figure after several such stops was 46.5 per cent., which must be a record for a hand-brake test with this class of vehicle.

Fuel-consumption tests were made over a 5.9-mile circuit between Barton and Clophill. This is an undulating route carrying heavy traffic at times, so the conditions were not favourable to good results. The laden tests were made at an ambient temperature of 37° F. Because the radiator was not blanked, it is probable that under warmer conditions another 2 m.p.g. could be added to the three fuelconsumption rates recorded under load.

For the half-load tests, 36 of the 71 sandbags which formed the test load were removed, and on the unladen run the vehicle carried only driver, passenger and test equipment. Each stop made during all these tests was of 15-sec. duration and the engine was left idling each time.

The time-load-mileage factors resulting from the seven consumption tests made show that the Perkins engine effects considerable economy, particularly under simulated delivery conditions. During a normal day's work, with the load progressively detreasing, an average fuel-consumption rate of 30 m.p.g. should be obtainable, whilst 25 m.p.g. is not an over-optimistic figure to expect if engaged on collection and delivery ' work in urban areas.

From the results obtained during the tests, it will be seen that the Bedford 35-cwt. van has a good average overall performance, with the accent on economy and good braking. The large body makes it suitable for a variety of operations, ranging from local delivery to light inter-urban haulage. For that reason a full series of fuel-consumption tests was carried out, although the vehicle is larger than is normally put through a four-stops-per-mile trial.

General handling was entirely satisfactory. The suspension ironed out uneven road surfaces, with the result that delicate loads could he carried with safety, and steering is virtually unaffected by bumps.

The driving position is comfortable, but the range of adjustment is limited to fore-and-aft movement. The bodybuilders have raised the scat by 1 in. above the standard position to improve forward visibility, but, even so, the large bulbous bonnet tends to restrict downward vision and both front wings are hidden.

The van is comfortable to drive, although purely as a matter of personal preference I would like a larger-diameter steering wheel. The pedals are light in operation and the gear lever is within easy reach. The pull-up hand-brake lever gives powerful emergency braking with the minimum of effort

Erskine noise, as heard in the body, is not abnormally loud, but when the power unit is set to idle very slowly a certain amount of vibration is transferred to the body and causes the roof panels to drum. At speeds above idling the bodywork is almost completely free from drumming and rattling.

Accessibility of Components Because of the time spent during the fuel-consumption tests, I was unable to conduct a series of maintenance tasks on the van, but established the accessibility of the components most likely to need attention during normal service. I had the van raised up on a hoist to inspect the underside, from which it was apparent that the simple chassis layout makes for easy maintenance of the major components.

The engine compartment is large, because the same front-end assembly is used for fourand six-cylindered engines. The version with the Perkins P.4 oil engine has a large cowl between the front of the engine and the radiator, with the result that the power unit is set back more than would appear necessary.

Standard Transmission Line

This arrangement has been adopted so that a standard transmission line may be used. Despite the rearward mounting of the power unit, accessibility to it is reasonable and the injection pump, fuel filter, air cleaner, dynamo, timing case and dipstick are easy to reach.

When the counter-balanced alligator-type bonnet is fully raised its rear edge fouls the windscreen-wiper arms. This is because the windscreen line of the Spurling body is lower than that of the standard Bedford cab, hut the bonnet pressing is similar.

The Bedford oil-engined 35-cwt. van is sure to find favour with operators requiring a roomy, simple vehicle with a relatively low purchase price and low running costs. Furthermore, it has a useful top speed of over 50 m.p.h.