How Econofreight Transport gets the most out of its Sheets

Page 65

Page 66

Page 69

If you've noticed an error in this article please click here to report it so we can fix it.

D0 you take as much care of your sheets as you do of your latest vehicles? If the answer is " no ", then your sense of proportion as a haulage man is badly lacking. True, without a good and well-maintained vehicle you could not guarantee getting the goods through o their destination. But where is the sense in spending, ;ay, £5,000 on a vehicle and keeping it in tip-top condition f the goods it carries arrive at the "other end" in a lamaged condition because of the weather? The whole Jbject of the exercise, surely, is defeated.

If the goods are rejected on arrival at their destination, )r a haulier receives a claim for damage done while they vere in transit, the fault usually lies in two directions— sad loading or defective sheeting, both of which are the .esponsibility of the driver. Be that as it may, it is the haulier who, in the end, pays the piper in the form of .ompensation or loss of customer (or both) and it is up to him to ensure that every driver in his employ knows how b secure a load correctly and sheet and rope it, and make ertain that sheets are weatherproof and in good repair.

Sheeting is all important, for not only does it protect the load from the weather, but, when correctly applied and supported by good roping, it helps to hold a load on a vehicle. Moreover, when small items are carried it prevents pilfering and so on.

I have dealt elsewhere in this issue with how one particular operator--British Road Services Ltd.—sheets vehicles carrying cartons of tinned foodstuffs between London and Lancashire. To find out how an independent haulier deals with the whole question of sheeting, I visited Econofreight Transport Ltd., of Thornaby-on-Tees, and with the help of its general manager, Mr. Peter JelIcock, and his staff, I was able to find out how a large. general A-licensed haulier, responsible for more than a 100 vehicles, purchases, maintains and generally looks after its sheets and tarpaulins. The vehicles of Econofreight can be divided into two categories—tippers and flats—and this was the reason why this fleet was chosen. The tippers are mainly of the larger, eight-wheeled bulk-carrying variety. In contrast, the "general" vehicles carry mostly steel from Tees-side to all parts of the country, and bring back, as return loads, literally anything. The company, by the way, operates a nightly six-vehicle trunk run in each direction to London and Rotherham.

In its past financial year Econofreight spent no less than £1.600 on the purchase of new sheets. This, I understand, is no exceptional amount. The sheets are under the day-to-day control of the yard foreman, Ken Bolton, who has been connected with the company and its associates for more than 14 years. It is his responsibility to see that the vehicles are equipped with the requisite number of sheets, and that they are at all times in a state of good repair. Working on the principle that " a stitch in time saves nine ", a watchful eye is kept on all sheets—and it is up to the drivers to report damage and wear.

Econofreight, for the past six years, has obtained most of its sheets and tarpaulins from a local partnership, Tees

Tarpaulins, of Stockton-on-Tees. Tees Tarpaulins also carry out all repairing and patching (mainly caused by the sheets being pulled too tightly over sharp projections) and offer, where necessary, a 24-hour service.

The basic number of sheets to a flat vehicle is the usual three—two ordinary and a larger flysheet. These, respectively, are Websterweave Bo-flax general service, costing the company about 9s. a square yard, and Terylene/cotton 12 Rip/stop, costing 12s. 3d. a square yard.

For the bulk chemical tippers, and particularly those that carry urea, which tends to " sweat " under certain conditions, Plastolene Hot-rolled 950 sheeting is used—a P.V.C. laminated Terylene scrim. This replaced Hydex sheeting previously used on these vehicles—Econofreight, with the co-operation of LCJ. Ltd., having spent a considerable period of time experimenting to find the best type of sheet to meet the exacting requirements demanded in the carriage of urea. All ,tipper sheets used by Econofreight have reinforced corner patches.

The company is responsible for a large fleet of ordinary tippers, the fleets of Tarmac Roadstone Ltd. and D. TarrenLtd. These are equipped with jute 14/8 Green proof sheeting to cover, in the main, asphalt and other allied commodities—the object here being to prevent loss of heat during transit.

Apart from the basic sheets allocated to each vehicle, additional secondary sheets are carried. These are sheets down-graded. The flat vehicles carry several of these to cover steel. They are often used to cushion the ropes holding the loads, thus preventing excessive wear and tear. The tippers, too, carry older sheets for use with general return tipping traffic.

All sheets are supplied to Econofreight's specifications in colours to match vehicle livery. They are letterstencilled with the company's name. This serves two purposes. Easy identification should they be lost or stolen, and advertising purposes—the name is positioned on the tipper sheets so that it can be read easily by pedestrians and others. In addition to bearing the company's name, all sheets are marked with a code number which enables the yard foreman, at a glance, to tell when the sheet was bought, and so on. For example, one of the sheets that I was shown bore the numbers 545, which indicates, I was told by Mr. Molton, that it was the fifth purchase in the fourth month. The last figure showed that the sheet was No. 5 in that particular batch. "We can check up on how long it has lasted ", Mr. Molton told me.

How does Econofreight ensure drivers are capable of sheeting a vehicle? This, too, is taken care of by the yard foreman, whose duty it is to test each new driver that is taken on. He is specifically asked if he can sheet a lorry and, when he returns with his first load, it is inspected. In most cases, of course, sheeting and roping is carried out at the loading points and it is the driver's responsibility to see that this is done properly. Normally he carries out this task alone, but if the load is exceptionally high or large, and in cases of urgency, a second man accompanies the vehicle to assist.

Talking in terms of steel loads—and Econofreight has is its largest customer Dorman Long (Steel) Ltd. and is .esponsiblefor the working of the Cleveland articulated ;cheme which is currently in the licensing news-1 asked V1r. Jeficock when vehicles were sheeted, and why. He :old me that originally people buying shot-blasted steel for use in buildings and so on, which was being delivered direct :o the site, insisted on the material being sheeted. In any .-.ase steel sheets, prone to rusting, had always been sheeted ts a matter of course. But, because more and more of he steel being used for constructional purposes must not trrive at the site in a damp condition, sheeting in steel iaulage is becoming prevalent. Usually, I was told, the ictual order form specifies that the steel shall be sheeted.

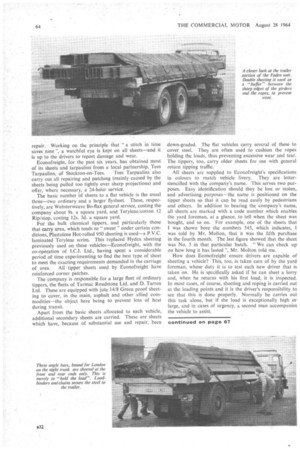

There are certain difficulties attached to the sheeting of 'abricated steel which comes in all shapes and sizes. Imagine the problem of completely sheeting steel that is ning conveyed on a, " skeleton " trailer, where the under.

side as well as the top is exposed to the atmosphere. Steel rods and bars are often loaded with an overhang fore or aft. The protusions have to be virtually wrapped up with sheeting.

To prevent excessive wear on ropes, and to ensure that rods or bars do not become dislodged during transit, vehicles are sometimes partially sheeted, as illustrated in the accompanying photograph.

A Matter of Common Sense

This, then, is how Econofreight Transport gets the maximum amount of use out of its sheets but, speaking generally, this is very much a matter of common sense. As a representative of Tees Tarpaulins told me, the condition of a sheet depends entirely on the driver. Some drivers wear them out in weeks; others can keep them in peak condition for years. By taking simple precautions, like Econofreight, years of life can be had out of sheets (I was shown sheets in Econofreight's store that had been purchased six years ago. Although downgraded, they were still in good and usable condition).

Care of sheets, as a matter of vital importance, should , he instilled into every driver taken on. At, maybe, £30 or more a time, no haulier can afford to neglect this aspect of his business.