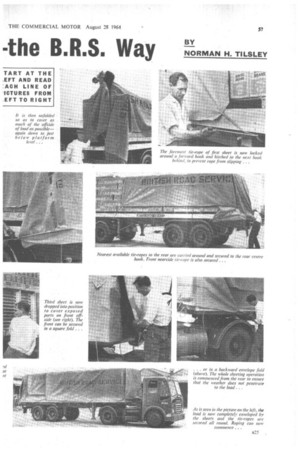

Covering and Securing a L -the B.R.S. Way

Page 58

Page 59

If you've noticed an error in this article please click here to report it so we can fix it.

BY NORMAN H. TILSLEY

TATTY sheets billowing in the slipstream; ropes, frayed and dangling. These are all too common a sight on goods vehicles nowadays and poses the question: Are the "younger set" of drivers capable of sheeting and roping a load effectively? More important than this, have they been shown the correct way to do so?

With this in mind we approached British Road Services, who were kind enough to offer a loaded vehicle and experienced shunt driver to demonstrate the way B.R.S. sheet and rope cartoned goods leaving the Harlesden (London) factory of H. J. Heinz and Co. Ltd., destined for their Kit Green (Lanes) factory via the B.R.S. nightly trunk service from Hampstead.

With over 20 years' experience in road haulage, driver H. Ayres, of the Hampstead depot, was using as a model a Bristol tractive unit and a brand new Taskers tandemaxle semi-trailer. As shunt drivers with Heinz, he and his driver colleagues are responsible for the loading of trailers, under B.R.S. representative Mr. J. M. Pratt. "It is our job ", he told me, "to ensure that these cartons are sheeted in such a fashion that there are no 'burn marks' on the cartons when they arrive at their Lancashire destination and that the weather does not penetrate. If they are damaged in any way, they are rejected and we (the drivers) are for it."

The trailers in use for this work at Hampstead each carry three canvas waterproofed sheets, plus five ropes. a24 In addition they carry about 30 corner boards, made of heavy fibre, to prevent the cartons from being crushed by the ropes.

Under ideal conditions the whole job should take a half to three-quarters of an hour. "When it is windy, it could take all day ", Ayres told me.