BIG:BET\ IS FAST

Page 42

Page 43

Page 44

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

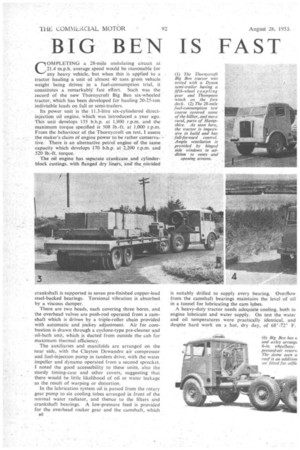

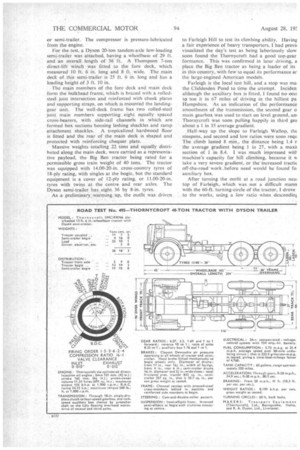

CO1VIPLET1NG a 28-mile undulating circuit at 21.4 m.p.h.. average speed would be reasonable for any .heavy vehicle, but when this is applied to a tractor hauling a unit of almost 40 tons gross vehicle weight being driven in a fuel-consumption trial, it constitutes a remarkably' fast effort. Such was the . record of the new Thornycroft Big Ben six-wheeled tractor, Which has been developed for hauling 20-25-ton indivisible loads on full or semi-trailers.

Its power unit is the 11.3-litre six-cylindered directinjection oil engine, which was 'introduced .a year ago. This unit develops 155 b.h.p. at 1,900 .r.p.m. and the maximum torque specified is 508 lb.-ft. at 1,000 r.p.rn. From the behaviour of the Thornycrofron test, I assess the maker's claim of engine power to be rather conservative. There is an alternative petrol engine of the same capacity which develops 170 b.h.p. at 2,200 r.p.m. and 520 lb.-ft. torque.

The oil engine has separate crankcase, and cylinderblock castings, with flanged dry liners., and. the nitrided

crankshaft is supported in seven pre-finished copper-lead steel-backed bearings. Torsional vibration is absorbed by a viscous damper.

There are two heads, each covering three bores, and the overhead valves are push-rod operated from a camshaft which is driven by a triple-roller chain provided with automatic and jockey adjustment. Air for combustion is drawn through a cyclone-type pre-cleaner and oil-bath unit, which is ducted from outside the cab for maximum thermal efficiency.

The auxiliaries and manifolds are arranged on the near side, with the Clayton Dewandre air compressor and fuel-injection pump in tandem drive, with the watet impeller and dynamo operated from a second sprocket. I noted the good accessibility to these units, also the sturdy timing-case and other covers, suggesting that there would be little likelihood of oil or water leakage as the result of warping or distortion.

In the lubrication system oil is passed from the rotary gear pump to six cooling tubes arranged in front of the normal water radiator, and thence to the filters and crankshaft bearings. A low-pressure feed is provided for the overhead rocker gear and the camshaft, which a8 is suitably drilled to supply every bearing. Overflow from the camshaft bearings maintains the level of oil in a tunnel for lubricating the cam lobes.

A heavy-duty tractor needs adequate cooling, both in engine lubricant and water supply. On test the water and oil temperatures were practically identical, and despite hard work on a hot, dry day, of 6V-72° F.

ent reading, the oil and water temperatures were led within 120-130° F. In its water cooling, the nycroft oil engine has thermostatic control to keep .1ylinder block warmer than the heads, and the ity of the system is 15 gallons. A six-bladed 18-in. eckleel fan is employed, having a beltdrive from diet. gear. The four-speed gearbox is similar to the Antar type, having a cast-iron housing and dog-clutch engagement for the straight-toothed gears on the top, second and third ratios,,and. a sliding gear for low and reverse. It is attached as a unit with the engine and clutch, and the two-speed. auxiliary box is bolted to the rear of the main-gearbox casting. I was impressed with the robust construction of the vehicle as a whole, and to exemplify. the sturdiness of units, the engine, complete with clutch, weighs 1 ton 5i cwt., main gearbox 4 cwt., and the auxiliary box 21 cwt.

Big Ben is likely to be required to operate off road, and for this purpose is provided with a single-spring-type bogie, arranged for a 12-in, difference in wheel levels diagonally, and a 6-in variation in axle levels. The suspension system includes an inverted semi-elliptic spring at each side, attached to the axles through large ball-ended trunnions to prevent twist being transmitted to the main leaf.

Driving and braking torque is controlled by radius.arms, coupled to the centre cross-tube of the bogie by a rubber-bushed link. The drive from the gearbox is transmitted through Hardy Spicer shafts to overhead worm gears of 8i-in. centres, but there is no intermediate differential.

The frame is of rigid construction, having II-in.-deep side-members and substantial cross-members bolted in position. It is reinforced at the bogie,'and in addition to the sub-frame carrying the fifth wheel, has a massive rear cross-member for an unsprung trailer coupling. A Darlington 25,000-lb. winch can be provided as an optional extra.

In the braking system there are two air reservoirs and separate cylinders for each wheel. A two-line airpressure system with couplings is fitted for the /railer

or semi-trailer. The compressor is pressure-lubricated from the engine.

For the test, a Dyson 20-ton tandem-axle low-loading semi-trailer was attached, having a wheelbase of 29 ft. and an overall length of 36 ft. A Thompson 7-ton direct-lift winch was fitted to the fore deck, which measured 10 ft. 6 in. long and 8 ft. wide. The main deck of. this semi-trailer is 25 ft. 6 in. long and has a loading height of 3 ft. 10 in.

The main members of the fore deck and main deck form the bulkhead frame., which is braced with a rolledsteel joist intersection and reinforced With cheek plates and supporting straps, on which is mounted the landinggear unit. The well-deck frame has two rolled-steel joist main members supporting . eight equally spaced cross-bearers, with side-rail channels in which are formed box sections housing lashing shackles and ramp attachment shackles. A tropicalized hardwood floor is fitted and the rear of the main deck is shaped and protected with reinforcing chequer plate. .

Massive weights totalling 22 tons and equally distributed along the main deck, were carried as a representative payload, the Big Ben tractor being rated for a permissible gross train Weight of 40 tons. The tractor was equipped with 14.00-20-in. cross-country tyres of 18-ply rating, with singles at the bogie, but the standard equipment is a cover of 12-ply rating, or 11.00-20-in. tyres with twins at the centre and rear axles. The Dyson semi-trailer has eight 36 by 8-in. tyres.

As apreliminary warrning,up, the outfit was driven to Farleigh Hill to test its climbing ability. Having a fair experience of heavy transporters, I had previi visualized the day's test as being laboriously slow soon found the Thornycroft had a good top-gear formance. This was confirmed in later driving, a place the Big Ben tractor as being a leader of its in this country, with few to equal its performance ar the large-engined American models.

Farleigh is the local test hill, and a stop was ma. the.. Cliddesden Pond to time the attempt. Inciden although the auxiliary box is fitted, I found no occ to use it in 67 miles of driving in the hilliest pa Hampshire. As an indication of the performance smoothness of the transmission, the second gear o main gearbox was used to start on level ground, an' Thornycroft was soon pulling happily in third gea about a 1 in 35 average gradient.

Half-way up the slope to Farleigh Wallop, the steepens, and second and low ratios were soon requ The climb lasted 8 min., the distance being L4 n the average gradient being 1 in 27, with a maxii section of I in 8.4. I was much impressed witlmachine's capacity for hill climbing, because it w take a very severe gradient, or theincreased tractic off-the-road'work.before need would be found fo. auxiliary box.

After turning the outfit at a road junction new top of Farleigh,, which was not a difficult mama with the 60-ft. turning-circle of the tractor, I drove to the works, using a low ratio when descendini The steering effort required was not unreasonable corresponded favourably with any rigid multi!ler: the clutch and gear change were positive but to operate. The organ-type brake pedal seemed ;ual at first, but within a few miles I preferred it to ;onventional pad.

te 65-gallon tank was filled to the overflow point le works before embarking on the 28-mile fuel umption route, which incorporated Whitchurch on mtward leg, and branched off towards Winchester, fling through Micheldever on the A303 and A30 s. I consider the Thornycroft 11.3-litre unit to be ably the quietest and smoothest-running oil engine milt at Basingstoke, and that it can compete with v contemporarV units in its .low noise level. The nal air-intake is an aid in reducing induction roar, the insulated bonnet is effective in minimizing heat noise.

; Ben was soon showing its paces by travelling at tp.h., and it took a reasonable slope before an ect gear was called for. The machine being smooth -easonably quiet, the need for a better horn was felt t threading this 50-ft.-Iong by 8-ft wide unit through the . congested streets of Whitehurch and Basingstoke.

1 liked the way in which Big Ben tackled the hills at speed, and with quick changes to third gear at 18 m.p.h., and second gear at 10 m.p.h., the outfit was kept moving at a lively pace. Apart from a deadlock in Basingstoke, caused by vehicles being parked without respect for corners and islands, nothing untoward happened during the fuel-consumption tests. Low gear was required once only when climbing the rise to Buffington Cross, but from my later observations even this may not have been necessary.

The schedule of 21.4 m.p.h. for the course has already been mentioned, and 39.15 pints of fuel were added to replenish the tank. This corresponds to 5.72 which is a reasonable average for any vehicle pulling such a load at lower speed.

I drove to Blackbushe Airport for acceleration and braking tests, and purposely delayed gear changing when climbing the inclines en route. The torque range was unusually good, and if any reliance can be placed on speedometer readings at low speed, the tractor pulled happily in second gear at 2 m.p.h. on a sharp gradient. Top gear can be used on level ground from 12 m.p.h. Without any suggestion of protest from the propeller. shaft couplings.

Braking Above Average There was too much traffic to make emergency stops from 30 in,p1h., but acceleration tests were conducted up to that Speed.. On an average of four runs in two directions, the outfit was stopped in 41 ft. from 20 m.p.h., which corresponds to 10 ft. per sec per sec. A deceleration of 9 ft. per sec. per sec. is accepted by brake manufacturers as being a good standard for the 30-40-ton articulated unit. The wheel marks during braking showed the tractor bogie wheels to be locking and front tyres marking heavily on the road. The semitrailer brake drums were barely warm at the end of the The acceleration figures justified my observations ein' the performance of Big Ben, 0-20 m.p.h. taking 34.9 sec. and 30 m.p.h. 80,5 sec. This acpeleration rate is not appreciably slower than many of the articulated units of nominal load capacity at present on the road, neither is it far behind some of the eight-wheelers loaded to 22 tons total weight. I respected the T-hornycroft in the initial stages of the run, and liked it still more by the end of the day.