ENGINE MAINTENANCE.

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

Useful Ideas Carried into Effect by Our Driver and Mechanic Readers.

WE ARE awarding the 15s. prize this week to "Wit.," of Leeds, for his description of a practical repair to the cylinder of a• K-tyPe.Karrier. The water-jacket covers_ to the .cylinders Of the engine fitted to this type of vehicle are secured by means of long studs, which Serve a 'double purpose. Besides holding the jacket covers, they also secure small covers which close. holes which are made; presumably for convenience when manufacturing, in the tops of the cylinder combustion cham-:

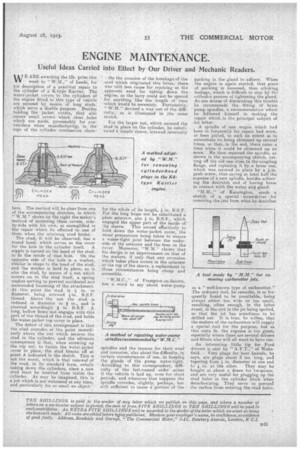

hers. The method will be clear from one of the accompanying sketches, in which " W.M." shows on the right the maker's method of mounting these covers, sideby-side with his own, as exemplified in the repair which he effected to one of them when the retaining stud broke.

The stud, it will be observed, has a round head, which serves as the cover for the, hole in the cylinder itself. A nipple is turned on the head of the stud,

to fit the inside of that hole. On the opposite side of the hole is a washer, similar in shape to the head of the stud, and the washer is held in place, as is also the stud, by -means of a nut which screws on to the stud itself, a spring washer serving to prevent accidental and unintended loosening of the attachment:

At this point the stud is in. in diameter, being strewed On. 13-S.F. thread. Above the nut the stud is reduced in dianieter to in., and is screwed accordingly in. B.S.F. A long, hollow brass nut engages with this part of the thread of the stud, and holds the water-jacket top cover in place.

The defect of this arrangement is that the stud corrodes at the point immediately above the nut which secures the stud in the cylinder, and the ultimate consequence is that, when screwing up the to nut, to fasten the water-jacket cover in place, the stud breaks off at point A indicated in the sketch. This is not the worst, which is that renewal of the stud, in its standard form, entails taking down the cylinders, since a new stud must be inSerted from inside the cylinder. As may be imagined, this is a job which is not welcomed at any time; and particularly for so small an object.

" On the occasion of the breakage of the stad which originated this letter,there was still less cause for rejoicing at the apparent need for taking down the engine,-as the lorry could not be spared for anything like the length of time which would be necessary. Fortunately, "W.-M." devised a way out of the difficulty, as is illustrated in the same sketch.

For the larger nut, -which secured the stud in place on the cylinder, he sUbstitoted a simple sleeve, screwed internally

for the whole of its length, in. B.S.F. For the long brass nut he substituted a plain setscrew, also in. B.S.F., which engaged the upper part of the inside of the sleeve. This served effectively to hold down the water-jacket cover, the usual precautions being taken to ensure a water-tight joint between the underside of the setscrew and the boss on the cover. Moreover, "W.11.4." claims that his design is an improvement on that of the makers, if only that any corrosion which takes place occurs in the setscrew at the top of the sleeve, a replacement in those circumstances being cheap and accessible.

" W.111.C.," of Frampton-on-Severn, has a word to say about water-pump

spindles and the reasons for their weak and corrosion, also about the difficulty, us 'certain circumstances of use, in keeping.. the glands of the pump water-tight. According to this correspondent, difficulty of the last-named order arises if the vehicle is laid up, even for short periods, and whenever that happens the spindle corrodes, slightly, perhaps, but still sufficient to cause a portion of the

packing in the gland to adhere. When the engine is again started, that piece of packing is loosened, thus 'allowing leakage, which is difficult to stay by th;', orthodox process of tightening the gland. As one means of diminishing this trouble he recommends the fitting of brass pump spindles, a recommendation which he followed himself in making the repair which,is the principal subject of his letter.

A spindle of one wagon which had been in frequently for repair had worn, or been pitted, to such an extent as to netessitate its being skimmed up several times, so that; in the end, 'there Came a time when it could be skimmed up no more: He then repaired the spindle, as shown in the accompanying sketch, cutting off the old one close to the coupling flange, and replacing it, by, a brass one, which was secured in place by a 1f-in. grub screw., thus saving at least half the expense of a new spindle, besides achieving the desirable end of having brass in contact with the water and gland.

"MM.," of Kensington, sends a sketch of a special screwdriver for removing the jets from what he describes as a "well-known type of carburetter." The ordinary tool, he remarks, is so frequently found to be unsuitable, being always either too wide or to small, resulting, often enough, in the latter event, in the slot in the jet being spoiled, so that the jet, has sometimes to be drilled out. It is true, he writes, that the makers of the carburetter will supply a special tool for the purpose, but as this costs 5s. the expense is too great, especially where there are several drivers and fitters who will all want to have one.

An interesting little tip for Ford drivers is sent by " A.V.T., ' of Wake field. Vent plugs for beer barrels, he says, are plugs about 3 ins, long, and tapering from ; in. diameter at one end to in, at tffe other. They may be bought at about a dozen for twopence, and are very useful for plugging up the stud holes in the cylinder block when decarbonizing. They serve to prevera the carbon from entering the stud holes.