SYSTEMATIC INSPECTION OF STEAM WAGONS.

Page 19

Page 20

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

How Efficiency in Running is to be Attained by the Keeping of Records and by a Scheme of Maintenance.

IN ORDER to obtain the most economical service from any motor wagon lc is imperative that the amount of time the wagon is out of service, undergoing -repairs, should be reduced to the minimum, The user who runs his machine until it actually breaks down, in spite of previous warnings that some parts require attention, has only himself to blame if his repair bill appears to be excessive. On the other hand, it is not necessary to have the fitter, or the driver, if he be capable, continually adjusting, altering, or titivating the wagon ; it is sur

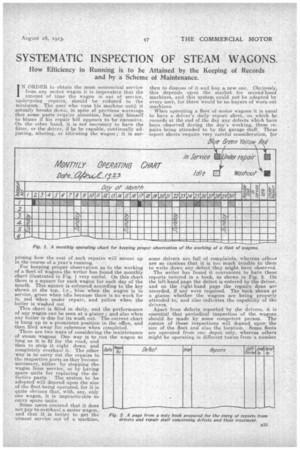

prising how the cost of such repairs will mount up in the course of a year's running. For keeping proper observation as to the working of a fleet of wagons the writer has found the monthly chart illustrated in Fig. 1 very useful. On this chart there is a square for each wagon for each day of the month. This square is coloured according to the key shown at the top, i.e., blue when the wagon is in service, green when idle because there is no work for it, red when under repair, and yellow when the boiler is washed out.

This chart is filled in daily, and the performance of any wagon can be seen at a glance ; and also when any boiler is due for its wash out. The current chart is hung up in a prominent position in the office, and 'then filed away for reference when completed. There are two Ways of considering the maintenance of steam wagon g One way is to run the wagon so long as it is fit for the road, and then to strip it right down and completely overhaul it.. The other way is to carry out the repairs to the respective parts as they become necessary, either by stopping the wagon from service, or by having spare units for replacing the defective 'parts. The system to be adopted will depend upon the size of the fleet being operated, for it is quite obvious that, with, say, only one wagon, it is impracticable to carry spare units. Some users contend that it does not pay to ove"rhaul a motor wagon, and that it is better to get the utmost service out of a machine,

then to dispose of it and 'buy a new, one. Obviously, this depends upon the market for second-hand machines, and this system could not be adopted by every user, for there would be no buyers of worn-out machines.

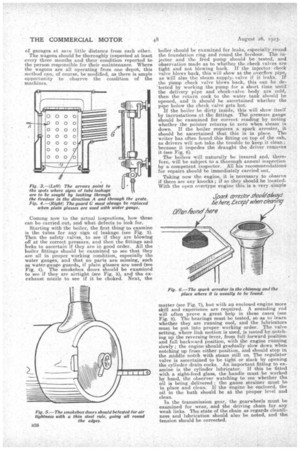

When operating a fleet of motor wagons it is usual to have a. driver's daily report sheet, on which he records at the end of the. day any defects which have been observed during the day's working, these repairs being attended to by the garage staff: These report sheets require very careful consideration, for some drivers are full of complaints, whereas otheis are so careless that it is too much trouble to them to write down any defect they might have observed.

The writer has found it convenient to have these reports entered in a book, as shown in Fig. 2. On the left-hand page the defect is entered by the driver, and on the right-hand page the repairs done are recorded, if any were required. The book shows at a glance whether the wagons are being properly attended to, and also indicates the capability of the drivers. Apart from defects reported by the drivers, it is essential that periodical inspection of the wagons should be made by some competent person. The nature of these inspections will depend upon the size of the fleet and also the location. Some fleets are operated from one depot only, whereas others might be operating in different towns from a number

of garages at save little distance from each other. The wagons should be thoroughly inspected at least every three months and their condition reported to the person responsible for their maintenance. Where the wagons are all operating from one depot, this method can, of course, be modified, as there is ample opportunity to observe the condition of the machines.

Coming new to the actual inspections, how these can be, carried out, and what defects to look for.

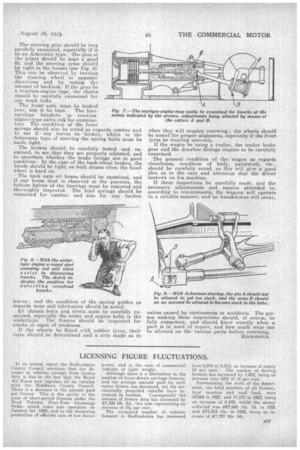

Starting with the boiler, the first thing to examine is the tubes for any sign of leakage (see Fig. 3). Then the safety .valves, to see if they are blowing off at the correctpressure, and then the fittings and iocks to ascertain if they are in goad order. All the boiler fittings should be examined to see that they are all in proper working condition, especially the water gauges, and that no parts are missing, such as -water-gauge guards if plain glasses are used (see Fig, 4). The ismokelMx doors should be examined to see if they are airtight (see Fig. 5), and the exexhaust nozzle to see if it be choked. Next, the boiler. should be examined for leaks, especially round the foundation ring and round the.firedoor.. The in jector and the feed pumpshould be tested, and

observation made as to whether thecheck valves are tight and not blowing back. If the injector check valve blows back, this will show at the overflow pipe, as will also the steam supply. valve if it leaks. If the pump check valve blows back, this can be detected by working the pump for a short time until the delivery pipe and check-valve body are cold, then the return cock to the water tank should he opened, and it should be .ascertained whether the pipe below the check valve gets hot.

Ifthe boiler be dirty inside, this will show itself by incrustations at the fittings. The pressure gauge

should be examined for correct reading by noting whether the pointer returns to zero when steam is down. If the boiler requires a spark 'arrester, it should be ascertained that this is in place. The writer has often found this fitting on top of the cab, as drivers will not take the trouble to keep it clean ; because it impedes the draught the driver removes it (see Fig. 6).

The boilers will naturally be insured and, there. fare, will be subject to a thorough annual inspection by a, competent inspector. All his recommendations for repairs should be immediately carried out,.

Taking now the engine, it is necessary to observe if there are any knocks; if so they should be located, With the open overtype engine this is a very simple

matter (see Fig. 7), but with an enclosed engine more skill and experience are required. A sounding rod will often prove a great help in these cases (see Fig. 8). The bearings must be tested, E03 as to learn whether they are running cool, and the lubricators must be put into proper working order. The valve setting, where link motion is used, is tested bynotching up the reversing-lever, from full forward position and full backward position, with the engine running slowly ; the engine should gradually slow down when notching up from either position, and should stop in the middle notch with steam still on. The regulator valve is ascertained to be tight or slack by opening the cylinder drain cocks. An important fitting to ex, amine is the cylinder lubricator. If this be fitted with a sight,-feed glass, the handle must be worked by hand, the observer watching to see whether the oil is being delivered the gauze strainer must be in place and clean. If the engine be enclosed, the oil in the bath should be at the proper level and clean.

In the transmission gear, the gearwheels must be examined for wear, and the driving chain for any weak links. The state of the chain as regards cleanliness and lubrication should also be noted, and the tension should be corrected. The. steering gear should be very carefully examined, especially if it be an Ackerman type. The pins at the joints should be kept a good fit, and the steering arms should be tight in the bosses (see Fig. 9). This can be observed by turning the steering wheel in opposite directions and by noting the amount. of backlash. If the gear be a traction-engine type, the chains Should ha carefully examined for any weak links.

The front axle must be looked ever, lest it. be bent. The fore.. carriage brackets in tractionengine-type axles call for examination. The condition of the front springs should also be noted as regards camber and to see if • any leaves be • broken, whilst in the Ackerman type of steering the spring bolts must be made tight.

The brakes should be carefully tested and examined, to see that they are properly adjusted, and to, ascertain whether the brake linings are in good condition. In the ease of the back-wheel brakes, the bands should be tight on both drums when the hand wheel is hard On.

The back axle oil boxes should be examined, and if any brais dust is observed at the journals, the bottom halves of the bearings must be removed and thoroughly inspected. The hind springs should be examined for camber, and also for any broken leaves ; and the condition of the spring guides as regards wear and lubrication should be noted.

All chassis bolts and rivets must be carefully examined, especially the boiler and engine bolts in the undertype. The frames should be inspected for cracks or signs of weakness.

If the wheels be fitted with rubber tyres, their state should be determined and a note made as to

when they will require renewing ; the wheels should be tested for proper alignment, especially if the front tyres be wearing unevenly. If the wagon be using a trailer, the trailer brake gear and the drawbar fittings require to be carefully examined.

• The general condition of the wagon as regards cleanliness, condition of body, paintwork, etc., should be carefully noted, as this will give a goo' idea as to the care and attention that the driver bestows on his machine.

If these inspections be carefully made, and the necessary adjustments and repairs attended to, according to requirements, the wagons will operate in a reliable manner, and no breakdowns will occur, unless caused by carelessness or accidents. The person making these inspections should, of e,ourse, be fully competent, and should know exactly when a part is in need of repair, and how much wear can be allowed on the various parts before renewing.

HEP112ESTUS.