Truck-mounted forklifts offer huge productivity benefits. But, as Brian Weatherley

Page 62

Page 63

Page 64

Page 65

If you've noticed an error in this article please click here to report it so we can fix it.

reports, it would be foolhardy to fit the kit without obtaining the training.

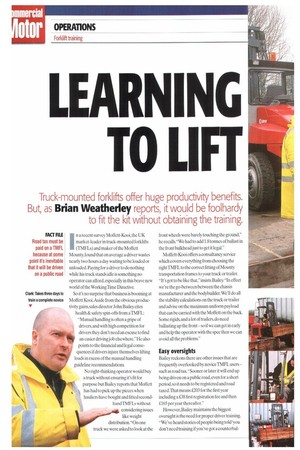

In a recent survey Moffett-Kooi,the UK market-leader in truck-mounted forklifts (TMFLs) and maker of the Moffett Mounty, found that on average a driver wastes nearly two hours a day waiting to be loaded or unloaded. Paying for a driver to do nothing while his truck stands idle is something no operator can afford,especially in this brave new world of the Working Tune Directive.

So it's no surprise that business is booming at Moffett Kooi.Aside from the obvious productivity gains, sales director John Bailey cites health & safety spin-offs from a TMFL: "Manual handling is often a gripe of drivers, and with high competition for drivers they don't need an excuse to find an easier driving job elsewhere." He also points to the financial and legal conse quences if drivers injure themselves lifting loads in excess of the manual handling guideline recommendations.

No right-thinking operator would buy a truck without ensuring it's fit for purpose but Bailey reports that Moffett has had to pick up the pieces when hauliers have bought and lined second hand TMFLs without considering issues like weight distribution."On one truck we were asked to look at the front wheels were barely touching the ground," he recalls."We had to add 1.8 tonnes of ballast in the front bulkhead just to get it legal."

Moffett-Kooi offers a consultancy service which covers everything from choosing the rightTMFL to the correct fitting of Mounty transportation frames to your truck or trailer. "It's got to be like that," insists Bailey:in effect we're the go-between between the chassis manufacturer and the bodybuilder.We '11 do all the stability calculations on the truck or trailer and advise on the maximum uniform payload that can be carried with the Moffett on the back. Some rigids,and a lot of trailers,do need ballasting up the front —so if we can get in early and help the operator with the spec then we can avoid all the problems"

Easy oversights

Bailey reckons there are other issues that are frequently overlooked by novice TMFL users — such as road tax."Sooner or later it will end up being driven on a public road,even for a short period,so it needs to be registered and road taxed.That means £203 for the first year including a £38 first registration fee and then £165 per year thereafter."

However,Balley maintains the biggest oversight is the need for proper driver training. "We've heard stories of people being told 'you don't need training if you've got a counterbal ance forklift licence:— but that's wrong. If you buy a Mounty then you'll need training on it and training to full certification."

In case there are any Commercial Motor readers who beg to differ it's worth drawing their collective attention to the requirements of employers (and employees) under the Health & Safety at Work Act (HASWA) and more importantly the Provision and Use of Work Equipment Regulations or PUWER.

Within section 2.1 of HAS WA on the 'General duties of employers to their employees' it clearly states that: "It shall be the duty of every employer to ensure,as far as reasonably practicable,the health. safety and welfare at work of all their employees." Then, within section 2(C), it goes on to say that:"The matters to which that duty extends include in particular the provision of such information, instruction, training and supervision as is necessary to ensure, so far as reasonably practical. the health and safety at work of their employees."

So giving an untrained driver a truckmounted forklift and inviting them to 'have a go' with it would clearly fall foul of that extremely broad safety criteria.

Set in stone Likewise the PUWER regulations emphasise the need for equipment training and risk awareness.Finallythe HSE's own Approved Code of Practice (ACOP) for Rider-operated lift-trucks: Operator Training states:" Employers should not allow anyone to operate,even ...occasionally, lift trucks within the scope of the ACOP. who have not completed basic training and testing..."

Thus Bailey is adamant that the regulations are clearly 'equipment specific' — ie if you're going to use a Moffett forklift then you need to be trained on one. Having a 'generic' counter balance ticket will not cover you to use one. "Under the accreditation scheme you need to get a licence that identifies the actual equipment you have been trained and tested on," says Bailey."We know of one company which didn't want to get its drivers trained for a TMFL and the operators of a construction site wouldn't let their drivers on to it."

Moffett-Kooi offers equipment training via 1111" Cheshire-based independent training provider Safe Handling with its courses accredited under the RI [113 and National Plant Operators Registration Scheme (NPORS).

Safe Handling can provide driver training either at Moffett's Coventry HQ or at an operator's premises. At the end of the course — assuming they pass—drivers end up with a Moffett Mounty ticket/identity card within either the RTITB, or National Plant Operators Registration Scheme, accreditation schemes.

Different needs

The syllabus for either is broadly similar, being a mixture of roughly 80% practical and 20% classroom work finishing with a physical test on a machine in order to demonstrate proper skills in driving/manoeuvring, including in confined spaces, lifting, stacking/de-stacking and naturally enough the all-important process of mounting and dismounting the TMFL onto its truck or trailer `mothership'.

If a driver fails the test they won't get a ticket. As SH trainer Wayne Clarke says:"I've known people to fail.1 had one driver who had absolutely no co-ordination—in fact I wondered how he ever got his HGV driving licence. You can also have problems when a company tries to cut corners and says 'Oh yes, he drives a forklift all the time —he won't need much training on a Moffete.Then when we get there we find he only uses a fork-truck occasionally."

However,a counterbalance fork truck licence is an advantage when it comes to handling a Moffett. 'If I was training a complete novice on a Mounty it would take around three days,"reckons Clarke. But if you have existing fork truck experience that would be reduced.A great percentage of people we train have fork truck experience and they needless time on the machine." Cost for a training course is around£500 including the cost of the identity/accreditation card based on a'novice' trainee and at the operator's premises.

ATMFL licence gained through the various accreditation schemes (any training provider must be accredited to one or more of the recognised bodies) is valid for three years although strangely, within the ACOP there's no mandatory requirement for retesting or reassessment or indeed any set interval period before a refresher course is necessary Clarke agrees that this is something of a loophole-but for an employer to fully meet their'duty of care' obligations to employees under the existing regs, they'll inevitably be providing a regular assessment to TMFL drivers-That makes sense and the best time to do it is just before the license expires.That way you can be sure a driver hasn't picked up any bad habits" Assessment may seem an unnecessary cost, but if a driver has a reportable accident, assessment and refresher training will be the first things the HSE asks about.That alone makes it a worthwhile investment. it MO UNTY TRAINEE CMrecently attended a Moffett Mounty training course run by Safe Handling's Wayne Clarke. While a Mounty shares many similarities with a normal counter-balance fork-lift such as its steering and manoeuvrability, as well as mast and fork controls, it's very different when it comes to lifting or dropping off a load. Unlike a counter-balance truck there's no weight on the back of a Mounty to stop it tipping forward when it lifts a heavy load. Instead the Moffett uses hydraulically-powered front stabiliser legs to hold it level while it picks up a pallet-then via its moving Teach-mast' the load is retracted inside the Moffett's 'stability' triangle where its centre of gravity sits pretty much between its front and rear wheels. Once the load is safely within that triangle you can then raise the stabilisers (and if its narrow enough. to lower it between the two wheeled outriggers) before setting off.

Across two days of individual tuition we found the course content well structured and above all else well-paced, with the theory side never allowed to become boring-thanks

to a good mix of 'flipchart', course literature and video presentations. The trainee gets to grips with a Mounty from the very start through a practical vehicle walk-around and safety check before progressing to actual driving, manoeuvring and lifting. The multiple-choice theory test paper on the first day effectively re-caps all the student learns about stability and general safety.

The mounting and demounting process is also straightforward although you have to remember that some controls need to be operated in reverse -for example, in order to raise the Mounty off the ground when mounting you have to lower the forks. The practical test, lasting around 45 minutes, is designed to show the student has complete control of his machine. Our test, conducted on the afternoon of the second day included demounting the Mounty before undertaking a series of loading, stacking and manoeuvring exercises before finally remounting the machine again. Based on our experience (we passed) it would not overtax a competent driver and someone with existing fork-truck experience would be likely to progress fairly rapidly.