ew models extend goods range 28 tons

Page 78

Page 79

Page 80

Page 81

Page 82

If you've noticed an error in this article please click here to report it so we can fix it.

BRIEF announcement was made by the Ford Motor Co. at the time of the Commerical Motor Show last September that it intended to enter the maximum-gross goods-vehicle field with 16-ton-gross rigids and up to 28-ton-gross tractive units. Full details of the new models called the 01000 ---can now be revealed.

The range forms an extension of the D Series announced almost exactly two years ago and it is interesting that with the Transit van range which was introduced in October 1965 this gives Ford a goodsmodel spread from 12 cwt. payload capacity to 28 tons g.t.w. which is probably the most comprehensive ever offered by a single European manufacturer.

The cab fitted to the D1000 is basically the same as the unit employed on the D Series but the Custom design with improved interior trim as standard and a horizontal anodized-aluminium band on the front panel distinguishes the unit from the D Series cab.

There are eight basic models in the new range comprising four haulage chassis for 16 tons gross, two tippers, a long wheelbase for 16 tons g.v.w. and a shorter chassis which will be plated for 15 tons but restricted to 14 tons in the UK because of its wheelbase. And there are two tractive units, one for operation at up to 24 tons g.t.w., the other for 28 tons g.t.w.

Cummins Vale 470 cu. in. lightweight V8 diesels are standard in the D1000. Two versions are used, one giving 170 b.h.p. gross (162 b.h.p. net) at 3,000 r.p.m. and 325 lb. ft. gross torque at 1,800 r.p.m. is used for rigid models; and a higher-powered version which is employed in the 24and 28-ton tractive units produces a maximum output of 185 b.h.p. gross (176 b.h.p. net) at 3,300 r.p.m. and a gross torque of 328 lb. ft. at 1,900 r.p.m.

twin-plate clutch

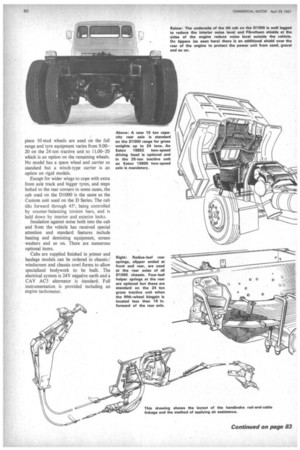

A Borg and Beck 12 in. twin-plate clutch has been developed specially for the D1000. And except for the 28-ton tractive unit the standard gearbox is a Turner T5C five-speed wide-ratio unit with synchromesh on the upper four gears with the option of a closeratio version of the unit. Ratios are 7.1, 3.88, 2.25, 1.48 and 1 to 1 forward and 7.07 to 1 reverse, and 6.75, 3.06, 1.81, 1.182 and 1 to 1 forward and 6.63 to 1 reverse respectively.

On the 28-ton tractive unit a ZF six speed synchromesh gearbox with ratios of 9.59, 5.47, 3.13, 1.89, 1.21 and 1 to 1 forward and 8.88 to 1 reverse is used and this unit is an additional option on the 24-ton tractive unit.

When the 2F box is specified in the 24-ton model an Eaton 19800 two-speed axle is mandatory and this transmission and axle arrangement is mandatory for the 28-ton tractive unit. In chassis having either of the Turner gearboxes, the standard rear axle is a new Ford design with 16 in. diameter spiral bevel crown wheel and the same basic unit but with an Eaton 18802 two-speed head is an option. The close-ratio Turner box is intended for use with this axle.

Various axle ratios are available and except for the 24-ton tractive unit all models have a new Ford 6.3-ton capacity front axle. On the 24-ton chassis a 4.25-ton front axle is employed. And when the 6.3-ton axle is fitted power-assisted steering is standard. This means that only the lighter tractive unit does not have this feature as standard although in this case it is an option.

The steering box used throughout the DI000 range is a Cam Gears worm and

peg unit and the power assistance is supplied through a specially developed Hydrosteer ram.

Although the road springs used on the D1000 have a higher capacity than those in the existing D Series they are to the same basic design. A change is that radius-leaf rear springs are used throughout, including tractive units; telescopic dampers are standard at all front axles.

Full air braking

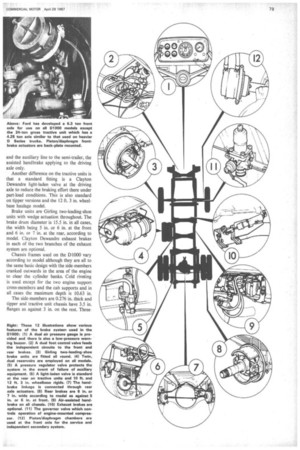

Full air-pressure dual-circuit braking has been adopted for the D1000. This is the first time Ford has used this type of system and the brakes have been designed to meet all current and probable legal requirements in countries in which the new range will be sold.

All models have an additional secondary system so the use of a split-circuit service brake system results in extra safety. But this is not of such significance on the tractive units where the service line to the semi-trailer is taken from the driving axle brake supply line and this means that if there is a failure in this portion only the front axle of the outfit will be braked.

Piston /diaphragm chambers are fitted at the front axles of all chassis with singlediaphragm units at the rear axle and there is an air-assisted handbrake, application being boosted by a diaphragm chamber acting on a relay lever in the linkage which is pressurized through a pull valve.

In the case of rigid models, air is fed by the pull valve to the pistons of the front diaphragms at the same time as the rear brakes are applied. But in the ease of tractive units the secondary system is provided through a hand valve in the cab which feeds air to the pistons of the front-axle chambers and the auxiliary line to the semi-trailer, the assisted handbrake applying to the driving axle only.

Another difference on the tractive units is that a standard fitting is a Clayton Dewandre light-laden valve at the driving axle to reduce the braking effort there under part-load conditions. This is also standard on tipper versions and the 12 ft. 3 in. wheelbase haulage model.

Brake units are Girling two-leading-shoe units with wedge actuation throughout. The brake drum diameter is 15.5 in. in all cases, the width being 5 in. or 6 in. at the front and 6 in. or 7 in. at the rear, according to model. Clayton Dewandre exhaust brakes in each of the two branches of the exhaust system are optional.

Chassis frames used on the D1000 vary according to model although they are all to the same basic design with the side-members cranked outwards in the area of the engine to clear the cylinder banks. Cold riveting is used except for the two engine support cross-members and the cab supports and in all cases the maximum depth is 10.63 in.

The side-members are 0.276 in. thick and tipper and tractive unit chassis have 3.5 in. flanges as against 3 in. on the rest. Three

Right: These 12 illustrations show various features of the brake system used in the 01000: (1) A dual air pressure gauge is provided and there is also a low-pressure warning buzzer. (2) A dual foot control valve feeds the independent circuits to the front and rear brakes. (3) Girling two-leading-shoe brake units are fitted all round. (4) Twin, dual reservoirs are employed on all models. (5) A pressure regulator valve protects the system in the event of failure of auxiliary equipment. (61 A light-laden valve is standard at the rear on tractive units and 10 ft. and 12 ft. 3 in. wheelbase rigida. (7) The handbrake linkage is connected through rear axle actuators. (8) Rear brakes are 6 in. or 7 in. wide according to model as against 6 in. or 6 in. at front. (9) Air-assisted handbrake on all chassis. (10) Exhaust brakes are optional. (11) The governor valve which controls operation of engine-mounted compressor. (12) Piston/diaphragm chambers are used at the front axle for the service and independent secondary system.

piece 10-stud wheels are used on the full range and tyre equipment varies from 9.0020 on the 24-ton tractive unit to 11.00-20 which is an option on the remaining wheels. No model has a spare wheel and carrier as standard but a winch-type carrier is an option on rigid models.

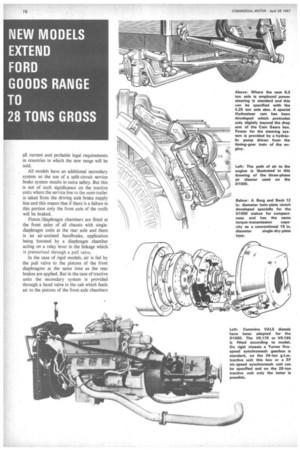

Except for wider wings to cope with extra front axle track and bigger tyres, and steps bolted to the rear corners in some cases, the cab used on the D1000 is the same as the Custom unit used on the D Series. The cab tilts forward through 450, being controlled by counter-balancing torsion bars, and is held down by interior and exterior locks.

Insulation against noise both into the cab and from the vehicle has received special attention and standard features include heating and demisting equipment, screen washers and so on._ There are numerous optional items.

Cabs are supplied finished in primer and haulage models can be ordered in chassis / windscreen and chassis cowl forms to allow specialized bodywork to be built. The electrical system is 24V negative earth and a CAV AC5 alternator is standard. Full instrumentation is provided including an engine tachometer.