Britain Can Make It

Page 82

Page 83

Page 84

If you've noticed an error in this article please click here to report it so we can fix it.

Says P. G. TUCKER

B'1 reason of its weight or overall dimensions, or both, an indivisible Load , may present a number of unusual problems in the design of the carrying unit. A designer has no great difficulty in calculating the strength of a beam to carry a given toad, or of assessing the number of wheels he will require to keep the tyre-loading figure within the recommended limits.

The Provision of facilities for loading and unloading is the greatest problem. In the case of a trailer which has to carry a heavy indivisible load, arrangements have usually to be made to lower the platform to ground -level. This means that either the rear-wheel or front-wheel assembly must be capable of being removed and replaced With reasonable facility, without Me use of equipment other than that inbuilt or carried on the trailer outfit.

During the past year or two there has been a number of instances in this country in which equipment has been built as a "one-off" job, obviously at great expense. This does not mean that the makers are not willing to repeat their designs, to meet either single orders, or those covering a number of units.

In some cases, of course, the equipment has been made for shipment overseas, but in others it has been built to meet a difficult transport problem at home. Machines designed for specialized use in the United Kingdom have a great overseas potential, as will be obvious from this review of a number of items of specialized equipment.

Towards the end of last year. Cranes (Dereham), Ltd., South Green Works. Dereharn, Norfolk, produced what was then the largest machine' trailer to be mounted on pneumatic tyres. The design was evolved after receiving an °Prier for a trailer capable of transporting an excavator weighing about 90 tons.

a4

Apart from the ingenuity shown in fabricating the main beams from channel-section steel members, which are braced by tubular cross-members, the method of releasing the rear bogie to enable the rear end to be dropped to ground level forms one of the outstanding features of the design.

This is achieved by building up a gantry from the massive box-section cross-member carrying the bogie crossshaft. This gantry "sits" on the head of a Norton 50-ton screw jack through the medium of which the back end of the trailer can be lowered and raised, for loading and reeoupling..

The two bogies each have eight wheels and these carry Dunlop 14.00 by 24.00 24-ply. tyres. A feature of the Crane bogie design lies in the mounting of the wheels in pairs on short axles Which are free to oscillate about a longitudinal beam, which itself is trunnion mounted. Thus, each of the 16 wheels is free to follow road contours with complete freedom of movement.

Another pneumatic-tyred trailer for heavy loads is that built by the Eagle Engineering Co., Ltd., Warwick. Of a total maximum weight of about 761 tons, the trailer weighs 16i tons, the designed loading capacity thus being 60 tons.

The main frame is built up of three longitudinal members of twin 15-in. by 4-in, rolled-steel channel, plated tap

and bottom. There are four, bogies, each of the two main bogies comprising two four-wheeled bogies. Thus there are 16 wheels, and these are fitted with 13.50-in. by

• 20-in, low-pressure tyres. The design of each four-wheel assembly is such as to provide for the rise and fall of individual wheels without restriction. For loading

• the trailer, the rear bogie assembly is made detachable,• the raising and eventual lowering of the rear end being accomplished by the use of separate jacks. Yet another trailer having a similar wheel arrangement to that on the Crane and Eagle outfits is the 50-ton pneumatic-tyred Dyson, built by R. A. Dyson and Co., Ltd., Grafton Street, Liverpool. An outstanding feature of this design is that the front and rear bogie assemblies, which arc steerable, can be turned through an angle of 90 degrees', thus enabling the trailer to be pulled -or pushed broadside on. Since the war, the big Oil companies have made extensive demands of British makers for specialized vehicles and equipment for arduous duties on oilfields. They are meeting these demands successfully, as is borne, out by the substantial orders which have been placed in this country for outfits of a. type previously obtainable only from America.

As an example, there are the Leyland Super-Hippo machines which are being supplied to the Royal Dutch-Shell

group of companies. The steel platform body, built by R. A. Dyson and Co., Ltd., is equipped with a winch driven from th& input shaft of • the auxiliary ,gearbox. Loads of 14 tons and over cart be handled by use of the winch alone:

There is an 8-in. diameter steel roller mounted at the rear of the platform. and as the load is

hauled o'er " .the roller it reaches. its.point of balance and falls to a horizontal rosition on the platform.

Provision is also male for the use of gin poles so that the hoisting gearcan also be used for mobile crane work.

An outfit which has the same lifting characteristic as the Leyland is the Commer Unipower platform truck built for the Shell Petroleum Co., Ltd. The chassis is a Commer underfloor-engined 7-tonner which incorporates modifications carried out by Universal Power Drives, Ltd., Perivale, Middlesex. The modifications include reinforced side members to the frame, the use of a Unipower four-wheeled bogie, winch gear with full-power operation, and the fitting of a large vacuum servobrake unit and transfer box.

When winching a heavy load, the angle assumed by the platform reaches about 30 degrees to the horizontal, the front wheels of the vehicle returning to the ground immediately the load passes over the centre of balance.

In another Commer-Unipower outfit, employing, a tractor and semi-trailer, loading is assisted by lowering the front end of the semi!trailer after the units have been . detached. The lowering operation is performed by the winch gear on thet,traetor.

Ehs principle of lowering the -froz.t, end is also adopted in the cas4 of a 12-wheeled trailer made D5 by the Eagle Engineering Co., Ltd. The fore carriage has first to be removed and this is achieved by lifting the body off it through the agency of inbuilt hydraulic jacks having a combined capacity of 40 tons.

As the wheels are of the twin type, there are 24 tyres in all-16 at the rear and eight on the fore carriage.

A 25-ton Servicing Unit

Oil-well servicing units had not until recently been made in this country. Those being built by Leyland Motors, Ltd., in conjunction with the Woodfield Hoist 'Co., of Rochester, for the Shell Petroleuni Co.,' Ltd., are a noteworthy achievement. The complete machine weighs about 25 tons, of which the tubular steel mast weighs 4/ tons.

The power unit of the Super-Hippo chassis is a Leyland 125 b.h.p. oil engine, a similar unit being employed to power the hoist.

The name of Scammell has always been associated-with vehicles capable of performing under abnormal conditions. One-of these is the maker's four-wheeldrive tipper chassis, which is powered by a Meadows 10.35-litre oil engine. Some idea of the versatility of this vehicle may be gauged from its ability to climb i 1-in-21 gradient, carrying a 12-ton load, without undue fuss. The gearbox provides six forward speeds, the lowest ratio being 95.59 to 1. This is through a-transfer box having a ratio of 1.31 to I. and a spiral-bevel-epicyclic rear axle having an overall reduction of 10.25 to 1.

Train Weight of 100 Tons

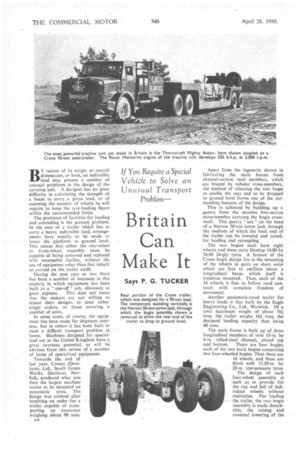

'Britain's most powerful road vehicle is the Thornycroft Mighty Antar tractor, which was built for service in Irak. Weighing 151 tons, it will operate with a gross train weight of 100 tons. The -power to achieve this is provided by a Rover Meteorite• eight-cylindered direct-injection oil engine developing 250 b.h.p. at 2,000 r.p.m. It develops a maximum torque of 725 lb.-ft. at 1,200 r.p.m.

The Kirkstall ,bogie on the Mighty Antar was designed for a groundreaction load of 36 tons. This bogie in itself represents an engineering achievement of no mean order.

Clayton Dewandre air pressure equip' ment is employed to give power assistance for operating the hand brake, foot brake and clutch. Power-assisted steering is also employed but, in this case, a hydraulic system, specially designed for the Mighty Antar, is used.

The semi-trailer with which the Mighty Antar is to be used is of Crane make, and rated at 45 tons. The major function of the outfit will be the carrying of 30-in.-diameter pipes measuring 93 ft. in length.

Vehicle and equipment makers in Britain have responded to the " save the dollars" call in a manner characteristic of the industry, and whether it be the quantity supply, of standard productions or a one-off job, overseas buyers will find that their needs can be met in this country.