B REEDING buses is a pastime enjoyed by relatively few inhabitants

Page 102

Page 103

Page 104

Page 105

If you've noticed an error in this article please click here to report it so we can fix it.

of this country. In fact, only in recent years has the hobby attained a degree of worldwide recognition, for in the earlier days of the transport industry the bus was something of a" sport," a neglected hybrid in the vehicle world, offshoot of a union between a goods chassis and a giant private-car body.

Modern views on the superiority of the human race, however, engendered a demand for something better in the way of passenger transport. The "40 hommes ou huit chevaux " idea is not acceptable to-day. With the extinction of this idea the design of passenger and goods vehicles diverged, and a new and much improved mode of transport was bout.

Greater comfort, improved performance and specialized design characterize the modern passenger vehicle. Native stock and foreign strains have been blended to produce a species retaining a native adaptability and revealing qualities of long life—a result of breeding from only the hardiest stock, with a distinction and air of good breeding which no other country can reproduce.

Progressive breeders of British bus stock have always been in the forefront of this evolutionary process. In their newest products may be seen not only the result of years of design progress, but a combination of qualities which makes the passenger vehicles of this country suited to the needs of operators all over the world.

Southall, in Middlesex, the home of A.E.C., Ltd., has been the birthplace of many famous names in the stud-book of modern passenger vehicles. Latest of these, the Regal Mark IV, is a model which looks forward to many years of future operation, and back to even more years of operating experience. On December 23, 1949, a description of the new model appeared in "The Commercial Motor." A record of the years of work that preceded this announcement will indicate some of the reasons why British buses play their present predominant role in passenger transport.

A.E.C., Ltd., is a comnany steered by a board of working directors. It is at their weekly meeting, under the chairmanship of the chief engineer, Mr. G. J. Rack ham, that new designs are first conceived. In the case of the Regal Mark IV, the conception dates back to 1939, when, in response to a demand in Canada for what was termed a "transit type" of bus, preliminary design work was undertaken, which, in 1940, resulted in an underfloorengined A.E.C. leaving for five years strenuous work in Canada.

War, meanwhile, diverted the thoughts of all to other matters. When peace returned in 1945, and production for civilian purposes was once more the uppermost thought in every manufacturer's mind, the need to build up vehicle strength again precluded the possibility of starting with new and untried designs. But, at least, designers could begin on projects for the future, and in the summer of 1946 the first decisions in this present history were taken.

Work on the transit type of vehicle was recommenced. The term in itself means little, merely indicating a vehicle with the power unit anywhere but in front, where horsed-bus tradition had located it. One-man operation was another feature implied in the term ; conventional forward control made this a difficult feat for any driver.

Recalling the lessons he had learnt on pre-war American visits, Mr.Rackham resumed his investigations on possible engine positions. By then the call for exports had begun, and it was towards discovering an agreeable compromise between home and overseas needs that efforts were directed.

Two solutions were considered : a transverse rear engine or an underfloor engine. The first made possible a compact transmission line at the cost of some 12 ins. of end space. No advantage was thus procurable as far as passenger space was concerned, because of the restrictions imposed by the British Construction and Use Regulations. Furthermore, this installation isolated the engine from the driver, so that he could not feel if all were not well with it. Reduced adhesion on the front wheels was another drawback of this layout.

Success of other underfloor engines and the possibility of devoting the whole of the chassis area to seating were the deciding factors. It was clear that 40 forwardfacing seats could be accommodated in a conventional chassis with the same overall dimensions as the current production models. Weight distribution could be much improved, better riding would be made possible by using longer front springs with increased deflection, and visibility from the cab would be vastly superior.

At this stage the new model consisted of an idea in the chief engineer's head, some rough sketches on the chief designer's pad, and an anticipatory smile on the sales manager's face. The design, experimental, purchasing and production departments were yet to make their contribution to the project. At the weekly meeting of the directors a decision was taken to build a prototype.

Work began in the drawing office. Carried out, as it is, by a number of individuals, the design effort can nevertheless be described only as the expression in visual form of the chief engineer's ideas. Throughout this stage of the work the team of specialists, comprising the design department, is inspired and directed by the experience, energy and the genius of the chief engineer. Eventually, from the boards come the drawings for the experimental department.

Acting as a buffer between the theoretical thinkers of the design department and the cash-concerned production and sales departments, is the experimental engineer. From the drawings of the theoreticians his section fashioned the components out of which was assembled the first Regal Mark W.

Seeking Out Shortcomings

This stage in the work may he considered as a physical check of the pencil tines produced on the drawing boards, and is the only satisfactory way of deciding, for example, how air piping should run, where the wiring should be fitted and other details. Such matters are difficult to complete in the drawing stage, and thus are worked out in the process of building the experimental model.

Then follows the testing of the completed vehicle, yet another method of checking the designers' work. Engine cooling, weight distribution, steering and road-holding are facets of the design which can be examined only on the road. Like the operators to whom subsequent prototypes eventually pass, the experimental engineers search out points for criticism and correction, and explore and explain the reasons for every feature of the new type.

Where, as in this case, the engine, too, is new, exhaustive bench tests are essential. In the underfloor engine, the chief engineer departed from standard A.E.C. practice, and chose a monobloc cylinder and crankcase, together with a form of dry-sump lubrication incorporating both scavenge and pressure pumps. Moreover, the new location of the fuel pump, for example, meant much investigation to ensure the delivery of the correct output of this component. Although dimensionally similar to earlier Regal engines and delivering a similar output, the Mark IV engine nevertheless underwent 18 months of test-bed running.

Impartial assessment of the design follows. With the sanction of the full board of directors, three pre-production models were built. One was sent to tour the municipal undertakings all over the country, and the other two were lent to large operators with wide experience. Criticism was courted, trouble was welcomed, for this was the stage at which the requirements of future buyers were to be studied, and modifications incorporated to suit all operators.

In building the pre-production models, the productioncontrol department assesses the drawings for its own purposes. Consultations take place with the processing department, the machine shop and the foundry to discover how much material already in stock can be used, what complicated production techniques will be required, and how the raw materials are to be converted into finished parts.

After a year of experimental service under various conditions, a report is drawn up by the general sales manager on the reception that the new model has received. Presented at a weekly meeting, it serves to indicate whether production should commence or not.

Preparation?, for Production

Tooling-up of the factory and the production of the foolproof jigs required to achieve selective assembly, start. At this stage the possible size of production has to be estimated in order to equate tooling costs. Work on the jigs must be meticulously timed and planned to the last minute, when into the shops will come, after perhaps five months of work, what is known as the longestdated part—the crankcase jig—together with jigs for the connecting-rod bolts, work on which began some 17 to 18 weeks tater.

Materials and parts ordered outside the parent organization must also arrive at that time. In all, 450 concerns will deliver, at the moment stated, the materials, the finished parts and specialized components with which full production commences.

By this time three years separate the first decisions and the first production model. What has been created in this period ? Only after many years of service can a faithful answer be given. Meanwhile design has taken a step forward.

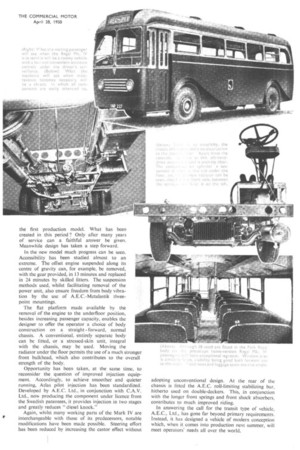

In the new model much progress can be seen. Accessibility has been studied almost to an extreme. The offset engine suspended along its centre of gravity can, for example, be removed, with the gear provided, in 13 minutes and replaced in 24 minutes by skilled fitters. The suspension methods used, whilst facilitating removal of the power unit, also ensure freedom from body vibration by the use of A.E.C.-Metalastik threepoint mountings.

The flat platform made available by the removal of the engine to the underfloor position, besides increasing passenger capacity, enables the designer to offer the operator a choice of body construction on a straight forward, normal chassis. A conventional, entirely separate body can be fitted, or a stressed-skin unit, integral with the chassis, may be used. Moving the radiator under the floor permits the use of a much stronger front bulkhead, which also contributes to the overall strength of the body.

Opportunity has been taken, at the same time, to reconsider the question of improved injection equipment. Accordingly, to achieve smoother and quieter running, Atlas pilot injection has been standardized. Developed by A.E.C. Ltd., in conjunction with C.A.V. Ltd., now producing the component under licence from the Swedish patentees, it provides injection in two stages and greatly reduces " diesel knock."

Again, whilst many working parts of the Mark IV are interchangeable with those of its predecessors, notable modifications have been made possible. Steering effort has been reduced by increasing the castor effect without adopting unconventional design. At the rear of the chassis is fitted the A.E.C. roll-limiting stabilizing bar, hitherto used on double-deckers. This, in conjunction with the longer front springs and front shock absorbers, contributes to much improved riding.

In answering the call for the transit type of vehicle, A.E.C., Ltd., has gone far beyond primary requirements. Instead, it has designed a vehicle of modern conception which, when it comes into production next summer, will meet operators' needs all over the world.