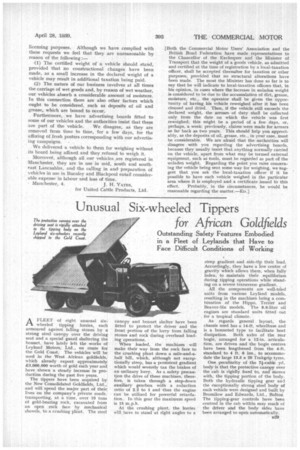

Unusual Six-wheeled Tippers

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

for African Goldfields

Outstanding Safety Features Embodied in a Fleet of Leylands that Have to Face Difficult Conditions of Working

AA FLEET of eight unusual sixwheeled tipping lorries, each armoured against falling stones by a strong steel canopy over the driving seat and a special guard sheltering the bonnet, have lately left the works of Leyland Motors, Ltd., en route for the Gold Coast. The vehicles will be used in the West African goldfields, which already export approximately £3,000,000 worth of gold each year and have shown a steady increase in production during the past five years.

The tippers have been acquired by the New Consolidated Goldfields, Ltd., and will spend the major part of their lives on the company's private roads, transporting, at a time, over 10 tons of gold-bearing rock, excavated from an open rock face by mechanical shovels, to a crushing plant. The steel canopy and bonnet shelter have been fitted to protect the driver and the front portion of the lorry from falling stones and rock during overhead loading operations.

When loaded, the machines will make their way from the rock face to the crushing plant down a mile-and-a'. half hill, which, although not exceptionally steep, has a persistent gradient which would severely tax the brakes of an ordinary lorry. As a safety precaution the drive of these machines, therefore, is taken through a step-down auxiliary gearbox with a reduction ratio of 2.2 to 1 and thus the engine can be utilized for powerful retardation. In this gear the maximum speed is 15 m.p.h.

At the crushing plant, the lorries will have to stand at right angles to a steep gradient and side-tip their load. Accordingly, they have a low centre of gravity which allows them, when fully laden, to maintain their equilibrium during .tipping operations while standing on a severe transverse gradient.

All the components are well-tried units from various Leyland models, resulting in the machines being a combination of the Hippo, Terrier and Beaver-Six models. The 8.6-litre oil engines are standard units fitted out for a tropical climate.

As regards general layout, the chassis used has a 14-ft. wheelbase and is a bonneted type to facilitate heat dissipation. Both axles of the rear bogie, arranged for a 12-in. articulation, are driven and the bogie centres have been lengthened from the 4-ft. standard to 4 ft. 6 ins., to accommodate the large 13.5 x 20 Trakgrip tyres.

One peculiarity of the 7k-cubic yd. body is that the protective canopy over the cab is rigidly fixed to, and moves with, the tipping portion of the body. Both the hydraulic tipping gear and the exceptionally strong steel body of each vehicle were designed and built by Bromilow and Edwards, Ltd., Bolton. The tipping-gear controls have been centred in the cab within easy reach of the driver and the body sides have been arranged to open automatically.