Modern Ideas in a Refuse Collector

Page 58

If you've noticed an error in this article please click here to report it so we can fix it.

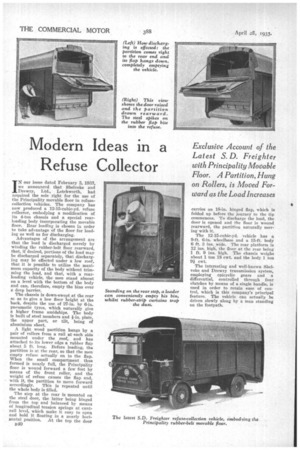

IN our issue dated February 3, 1933, we announced that Shelvoke and Drewry, Ltd., Letchworth, had acquired the sole right for the use of the Principality movable floor in refusecollection vehicles. The company has now produced a 12-15-cubic-yd. refuse collector, embodying a modification of its 4-ton chassis and a special rearloading body incorporating the movable floor. Rear loading is chosen in order to take advantage of the floor for loading as well as for discharging.

Advantages of the arrangement are that the load is discharged merely by winding the rubber-belt floor rearward, that, if desired, portions of the load may be discharged separately, that discharging may be effected under a low roof, that it is possible to utilize the maximum capacity of the body without trimming the load, and that, with a rearloading vehicle, the men stand almost on a level with the bottom of the body and can, therefore, empty the bins over a deep barrier.

The chassis is down-swept at the rear se as to give a low floor height at the back, despite the use of 27-in, by 6-in. pneumatic tyres, which naturally give a higher frame amidships. The body is built of steel members and It-in. plate, the upper part, or tilt, being of aluminium sheet.

A light wood partition hangs by a pair of rollers from a rail at each side mounted under the roof, and has attached to its lower edge a rubber flap about 5 ft. long. Before loading, the partition is at the rear, so that the men empty refuse actually on to the flap. When the small compartment thus formed is nearly full, the Principality floor is wound forward a few feet by means of the front roller, and the weight of refuse causes the flap and, with it, the partition to move forward accordingly. This is repeated until the whole body is filled.

The step at the rear is mounted on the steel door, the latter being hinged from the top and balanced by means of longitudinal tension springs at cantrail level, which make it easy to open and hold it floating in a nearly horizontal position. At the top the door B40 carries an 18-in, hinged flap, which is folded up before the journey to the tip commences. To discharge the load, the door is opened and the floor is wound rearward, the partition naturally moving with it. The 12-15-cubic-yd. vehicle has a 9-ft. 6-in, wheelbase and a 15-ft. body 6 ft. 3 ins. wide. The rear platform is 12 ins, high, the floor at the rear being 1 ft. 9 ins. high. The chassis weighs about 1 ton 18 cwt. and the body 1 ton 9i cwt.

The interesting and well-known Shelyoke and Drewry transmission system, employing epicyclic gears and a differential, controlled through four clutches by means of a single handle, is used in order to retain ease of control, which is this company's principal feature. The vehicle can actually be driven slowly along by a man standing on the footpath.