A REDESIGNED

Page 46

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

GUY Six -wheeled

TROLLEY-BUS

TIIE grouping of comporiants mid the general simplification of the electrical gear on trolley-bus chassis have been gradual processes, but each year a definite advance has been marked by manufacturers. Moreover, running efficiency has been increased by careful attention to detail, with the result that, on the score of running costs, appearance and maintenance expenditure, the trolley-bus, as a type, compares favourably with the more firmly established internal-combustionengined chassis.

Guy Motors, Ltd. Wolverhampton, a concern which has been a pioneer of this type of vehicle, has just redesigned its large six-wheeled, double-deck chassis and brought all keens of equipment thoroughly up to date, profiting by experience gained with the earlier models.

The frame side-members are pressings of the same type as previously used, but there has been an alteration in the disposition of various members at the

front, due to the motor having been placed farther forward; this arrangement gives a perfectly clear floor space in the lower saloon. The road springs, of Woodheud manufacture, are quite new, the first two leaves of each spring being wrapped round the eyes in order to give additional strength. It is now Possible to remove the rear springs without disconnecting the whole of the bogie, for the holding-down lolls have been reversed and the rear mudguard brackets redesigned to give sufficient clearance for the springs to be taken ont.

Another point which should be mentioned while dealing with the suspension is that provision has been made for fitting 10.5-in. low-pressure tyres.

Probably the most important item of all, however, concerns the layout of the

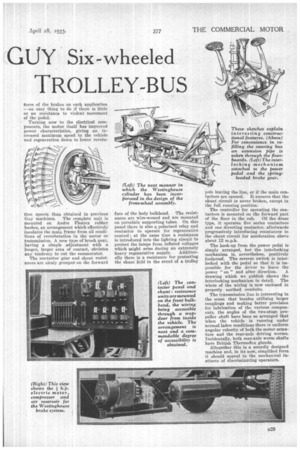

brake system. Although the chassis is designed so that compressed-air, vacuum or Lockheed hydraulic brakes can be used, we will confine ourselves to a description of the first-mentioned type, as the chassis inspected was equipped In this manner. On the side of the frame is a -h.p. Dull motor driving a Westinghouse two-cylindered air compressor. This outfit feeds a reservoir (situated close by on the off side of the chassis), the pressure being 110 lb. per sq. in. and the capacity sufficient to permit from 12 to 16 applications of the brakes to be made before the electric motor and compressor cut in again at 70lb. per sq. in.

Particular attention attaches to the Westinghouse cylinders on the front axle, for they are now mounted neatly at the tops of the king-pins, the movements of the pistons being transmitted through the pivots to a bell-crank lever at the foot of each pivot. Great care has been taken in the design to ensure that the linkages, leverages, etc., are geometrically correct.

There _are two shoes in each of the front drums and four shoes in each rear drum; the ratter are no less than 411ins. wide, and, as they form an almost complete circle, pressure is applied evenly throughout the circumference of the drums, and the friction surface is, of course, proportionately large. The pedal-applied system controls 1,088 sq. ins, of friction liners; the hand lever applies all shoes, except those in the front drums.

A point worth recording concerns the layout of the brake pedal, _fee,by a system of levers and springs, the pressure required for brakeactuation is progressively increased during the travel of the pedal. This, of course, tends to prevent the driver apply in the full

force of the brakes on each application —an easy thing to do if there is little or no resistance to violent movement of the pedal.

Turning now to the electrical components, the motor itself has improved power characteristics, giving an increased maximum speed to the vehicle and regeneration down to lower revolu tion speeds than obtained in previous Guy machines. The complete unit is mounted on Andre Floatex rubber bushes, an arrangement which effectively insulates the main frame from all conditions of reverberation in the motor or transmission. A new type of brush gear, having a simple adjustment with a longer, larger area of contact, obviates any tendency to cut the commutator.

The contactor gear and shunt resistances are nicely ;trouped on the forward

face of the body bulkhead. The resistances are wire-wound and are mounted on porcelain supporting tubes. On this panel there is also a polarized relay and contactor to operate for regenerative control ; at the same time a resistance is introduced into the lighting circuit to protect the lamps from inflated voltages which might arise during an extremely heavy regenerative supply. Additionally there is a resistance for protecting the shunt field in the event of a trolley

pole leaving the line, or if the main contactors are opened. It ensures that the shunt circuit is never broken, except in the full running position.

The controller for operating the contactors is mounted on the forward part of the floor in the cab. Of the drum type, it operates five series contactors and one diverting contactor, afterwards progressively introducing resistances in the shunt circuit for acceleration above about 12 m.p.h.

The hook-up from the power pedal is Simply arranged, but the interlocking mechanism is, nevertheless, positively foolproof. The reverse switch is interlocked with the pedal so that it is impossible for the driver to leave the power "on " and alter direction. A drawing which we publish shows the interlocking mechanism in detail. The whole of the wiring is now enclosed in properly earthed conduits.

The transmission line is interesting in the sense that besides utilizing larger couplings and making better provision for lubrication of the various components, the angles of the two-stage propeller shaft have been so arranged that when the vehicle is running under normal laden conditions there is uniform angular velocity of both the motor armature and the rear-axle driving worms. Incidentally, both rear-axle worm shafts have British Thermoflex glands.

Altogether this is a soundly designed machine and, in its new, simplified form it should appeal to the mechanical instincts of discriminating operators.