THE BRITISH FO

Page 16

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

ZOMPLISHMENT.

The Developments which Have Occurred Since the Road Transport Industry Has Benefited. N was Assembled in this Country in 1911. How ethods Employed to Obtain Rapid Production.

THE MAJORITY of those interested .;.n. road transport, if asked whether the Ford is a British or American product, would immediately say American' and yet they would be very far out in this statement. Certainly the Ford originated in America, but. so far as all those sold in this country are concerned they are now over 95 per cent. British in respect of material and 99.79 per cent. British in respect of workmanship. Following this up, it will be of interest to quote some of the 1924 figures. The wages paid and purchases made in the British Isles amounted to nearly £4,000,000; the highest number of employees at the Trafford Park Works, Manchester, was 3,322 and the minimum rate of wages paid to all grades was 3s. per hour. Sales to Continental countries from the British works amounted to nearly 2600,000, and it must be remembered that all profits made are retained in this country for the development of the British business.

Although all our readers may not agree with us, we consider that we have to thank the Ford for a considerable proportion of the immense development which has taken place during recent years in the use of mechanical road transport. At a time when the man in a small way of business could not possibly have afforded the capital cost of a heavy vehicle and when practically no light types were available at a reasonable figure, the Ford van, and, later, the ton truck, met his requirements and enabled him to take advantage of rapid transport and of a means by which his business could be spread over a much larger area.

The first Ford vehicle was sold in England in the year 1910, and in that year 570 was the total. The first Fords were a,ssembled in the British works in October, 1911, and production rapidly increased until between 1923 and April 17th, 1925, the production of British Fords was approximately 64,000. The particular date which has just been mentioned was notable in seeing the birth of the 250,000th Ford constructed in this country, excluding vehicles pro duced for export, this number, of course, including a large proportion of vans and ton trucks.

A large number of guests, including a representative of The Commercial Motor, was present when this vehicle left the runway. Before attending this

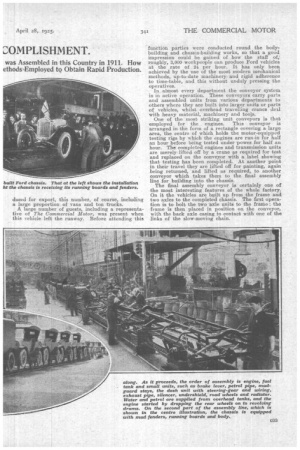

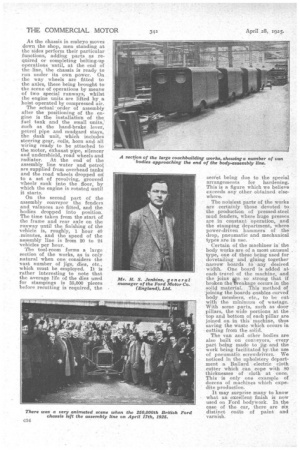

function parties were conducted round the bodybuilding and chassis-building works, so that a good impression could be gained of how the staff of; roughly, 3,000 workpeople can produce Ford vehicles. at the rate of 24 per hour. It has only been achieved by the use of the most modern mechanical methods, up-to date machinery and rigid adherence to time-table, and this without unduly pressing the operatives. In almost every department the conveyor system is in active operation. These conveyors carry parts and assembled units froni various departments to others where they are built into larger units or parts of vehicles, whilst overhead travelling cranes deal with heavy material, machinery and toots. One of the most striking unit conveyors is that employed for the engines. This conveyor is arranged in the form of a rectangle covering a large area, the centre of which holds the motor-equipped testing rigs by which the engines are run-in for half an hour before being tested under -power for half an hour. The completed engines and transmission units are merely lifted off by a crane 4s required for test and replaced on the conveyor with a label showing that testing has been completed. At another point in their travel they are lifted off for painting, again being returned, and lifted as required, to another conveyor which takes them to the final assembly line for building into the chassis.

The final assembly conveyor is certainly one of the most interesting features of the whole factory. On it the vehicles are built up from the frame and two axles to the completed chassis. The first operation is to bolt the two 'axle units to the fraine; the frame is then placed in position on the conveyor, with the back axle casing in .contact with one of the links of the slow-moving chain.

As the chassis in embryo moves down the shop, men standing at the sides perform their particular functions, adding parts as required or completing bolting-up operations until, at the end of the line, the chassis is ready to run under its own power. On the way wheels are fitted to the axles, these being brought to the scene of operations by means of two special runways, whilst the engine units are lifted by a hoist operated by compressed air. The actual order of assembly after the positioning of the engine is the installatiot of the fuel tank and the small units,' such as the hand-brake lever, petrol pipe and mudgard stays, the dash unit, which includes steering gear, coils, horn and all wiring ready to be attached to the motor, exhaust pipe, silencer and undershield, road wheels and radiator. At the end of the assembly line water and petrol, are supplied from overhead tanksi and the road wheels dropped on to a set of revolving, grooved wheels sunk into the floor, by which the engine is rotated until it starts.

On the second part of the assembly conveyor the fenders and valances are fitted, and the bodies dropped into position. The time taken from the start of the frame and rear axle on the runway until the finishing of the vehicle is, roughly, 1 hour 40 .minutes, and the speed of the assembly line is from 20 to 24 vehicles per hour.

The tool-room forms a large, section of the works, as is only natural when one considers the vast number of jigs, dies, etc., which must be employed. It is rather interesting to note that the average life of the dies used for stampings is 35,000 pieces before recutting is required, the secret being due to the special arrangements for hardening. This is a figure which we believe exceeds any other obtained elsewhere.

The noisiest parts of the works are certainly those devoted to the production of pressed-steel mud fenders, where huge presses are in constant operation, and the stamping department, where power-driven hammers of the drop, pneumatic and mechanical types are in use.

Certain of the machines in the body works are of a most unusual type, one of these being Used for dovetailing and gluing together narrow boards to any desired width. One board is added at each travel of the machine, and the joins bre so strong that if broken theTreakage occurs in the solid material. This method of joining the boards enables curved body members, etc., to be cut with the minimum of wastage. With some parts, such as door pillars, the wide portions at the top and bottom of each pillar are joined on in this machine, thus saving the waste .which occurs in cutting from the solid.

The van and other bodies are also built on conveyors, every part being made to jig, and the work being facilitated by. the use of pneumatic screwdrivers. We noticed in the upholstery department a Ballard electric cloth cutter which can cope with 80 thicknesses of cloth at once. This is only one example of dozens of machines which expedite production.

It may surprise many to know what an excellent finish is now used on Ford bodywork. In the case of the car, there are six distinct coats of paint and varnish.