TOTAL CONINUTN

Page 54

Page 55

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

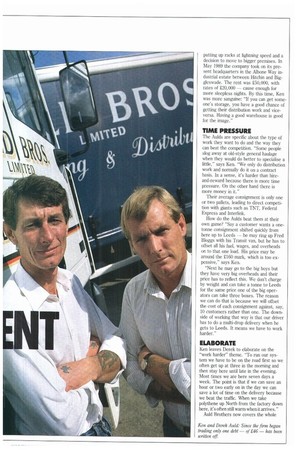

Less than five years ago Derek and Ken Auld were unemployed. Today they run a thriving distribution and warehousing company — a product of hard work and coping with big risks.

• It's all too easy to be blasé about stories of people who strike out on their own to set up a business. Images of cigarchomping rough diamonds spouting "I didn't get where I am today" home truths pop into your head. The Auld brothers give the lie to the image — ordinary men with no bluster who have made themselves extraordinary by taking a big risk and making a huge effort.

OUT OF POCKET

Less than five years ago Derek and Ken Auld were out of work and out of pocket. For the year ending July 1990, the turnover of their distribution and warehousing company reached £591,000. In short, this is a success story. But it is also a story of battling with the very institutions which should have been allies.

"We were both committed, we both knew haulage and we had secured a big customer," Ken recalls. "We planned to hire two small trucks rather than buy, to cut our risks and all we needed was a £4,000 loan to get us going. I put on my suit and went to meet the banks armed with a detailed profit forecast and letters of endorsement." It was disappointing.

"Barclays," says Derek, "just told us that the haulage industry is a graveyard second only to the building business. They didn't want to hear what we had to say. It was a bit of a shock, considering we were only looking for a small amount of backing." Midland at least lived up to its TV adverts by listening to the plan.

The bank manager at Midland told Ken: "Prove to me you can run a business and then you can get somewhere." The bank lent the Aulds the money they needed but so many strings were attached that they began to strangle any hope of expansion. "Midland put a legal charge on my house, which meant they could force me to sell it if I didn't keep up with loan repayments.

That put us under a lot of strain. I was able to pay off the loan within nine months (the agreement was one year) in order to lift the legal charge. Just as we thought we were proving ourselves the bank started playing up — you see we were bad customers in a sense because we never went overdrawn and we repaid all the loans early."

Crisis point came when the bank stopped a 29-a-week standing order for a mobile phone and froze the Aulds' current account. "It was quite funny in a way. They were giving billions in unsecured loans to Nicaragua but wouldn't help us even though we had our houses as equity," says Derek. They decided on a change of bank. "We didn't approach NatWest first time around and that was a mistake because we got a totally different response. We dealt with the main branch manager instead of an underling. He asked: 'What's your borrowing?' — 'nothing' — 'What's your overdraft' — I said 'nothing' — 'So what are you doing here?' he said. I explained the situation and he organised £10,000 unsecured and set up a meeting with the bank's in-house finance company, Lombard, who gave us the deal to buy our first truck."

Derek is convinced that this support marked a watershed for the company. "It was a real turning point because it meant we had the backing to expand with confidence. Before that we were swimming against the tide."

Once the tide was with them, the company moved fast. From a start-up date of March 1986, the Aulds projected a first year turnover of £60,000. In the event, they achieved £90,000. Ever since, their turnover increases have made sweet reading: 2220,000 in the second year: E368,000 in the third; and nearly £600,000 last year.

Initially Ken set up as a sole trader to simplify the paperwork and the business was run from home. "One of the reasons we have done OK is that we have never overstretched. We didn't go straight in and buy a big wagon on the never-never," explains Ken. The Aulds struck lucky with the hire company, Wilton Truck Rental of Luton and Stevenage, from which they hired two Ford Cargos in spring 1986: "They gave us a great deal on the trucks and the owner, Peter Ireton, turned out to be a real friend."

Before anything else, the brothers se

cured their first customer, a polythene manufacturer based in Berkshire, whose boss was an old acquaintance of Ken.

Ken recalls: "When he heard on the grapevine that I was going it alone he rang me at home, and said he was dissatisfied with the service he was getting. We met up when [had done some costings and we got the work."

Broadening the company's customer base was a matter of knocking on doors in Letchworth, Hitchin and Biggleswade. Customer number two was another gem — Chubb Fire Extinguishers — which turned into another long-term customer.

TAKING ADVANTAGE

All the while, Ken and Derek were taking advantage of every small business scheme going. Most important was the Government-backed Business Enterprise Initiative. Derek had briefly registered as unemployed and this allowed him access to the service. Next step was to prove they had £1,000 of capital directed into the firm through a banker's letter and the company accounts. This gave the Aulds three free consultancies with BEI accountants.

To ease cashflow problems Ken and Derek used Access credit cards to pay all fuel bills. "That way we could run the trucks for 30 days on credit, and as long as we paid off the bills in full we incurred no interest," says Derek. "If you use credit cards carefully, they can really help you along." It saves money on bank charges. Ken opened a Giro account because it levies no charge on its cheques.

The polythene manufacturer proved himself a friend as well as a customer when he offered the Aulds part of his yard as an operating centre. By the second year, however, the need to expand and to offer customers a forklift service dictated a move. They took on a 560m2

(6,000sqft) warehouse and yard at Tempsford. It was a big step and Ken especially remembers sleepless nights worrying how he was going to fill the warehouse with storage to offset the rent. "Ken was too successful," says Derek. "He was worried because we had no storage and within a month he was worrying about where we were going to put stuff."

Computer giant ICL rang and asked for 200 pallets to be stored. "We were full to bursting at Tempsford but when a company like ICL asks, you don't say 'no'," says Ken. The upshot was a hellish night putting up racks at lightning speed and a decision to move to bigger premises. In May 1989 the company took on its present headquarters in the Albone Way industrial estate between Hitchin and Biggleswade. The rent was £50,000, with rates of R20,000 — cause enough for more sleepless nights. By this time, Ken was more sanguine: "If you can get someone's storage, you have a good chance of getting their distribution work and viceversa. Having a good warehouse is good for the image."

TIME PRESSURE

The AuIds are specific about the type of work they want to do and the way they can beat the competition. "Some people slog away at old-style general haulage when they would do better to specialise a little," says Ken. "We only do distribution work and normally do it on a contract basis. In a sense, it's harder than hireand-reward because there is more time pressure. On the other hand there is more money in it."

Their average consignment is only one or two pallets, leading to direct competition with giants such as TNT, Federal Express and Interlink.

How do the AuIds beat them at their own game? "Say a customer wants a onetonne consignment shifted quickly from here up to Leeds — he may ring up Fred Bloggs with his Transit van, but he has to offset all his fuel, wages, and overheads on to that one load. His price may be around the £160 mark, which is too expensive," says Ken.

"Next he may go to the big boys but they have very big overheads and their price has to reflect this. We don't charge by weight and can take a tonne to Leeds for the same price one of the big operators can take three boxes. The reason we can do that is because we will offset the cost of each consignment against, say, 10 customers rather than one. The downside of working that way is that our driver has to do a multi-drop delivery when he gets to Leeds. It means we have to work harder."

ELABORATE

Ken leaves Derek to elaborate on the "work harder" theme. "To run our system we have to be on the road first so we often get up at three in the morning and then stay here until late in the evening. Most times we are here seven days a week. The point is that if we can save an hour or two early on in the day we can save a lot of time on the delivery because we beat the traffic. When we take polythene up North from the factory down here, it's often still warm when it arrives."

Auld Brothers now covers the whole country — England and Wales with its own trucks (with odd trips into Ireland), and Scotland through a close liaison with Causer Transport of Carlisle. Derek made the connection.

Another foundation for success has been an iron grip on credit control, as Ken explains: "I think that many haulage companies get into trouble because of poor credit control. One of our strong points is keeping things very tight," His wife Tracy holds the reins and is proud of the fact that, since the company began trading, it has only been forced to write off one debt — of £46 — and that, despite a turnover of nearly £600,000, the business has managed to hold itself to a £10,000 overdraft facility.

Accurate costings are a major factor. Ken and Derek buy all their trucks on finance lease deals complete with four-year Auld Bros repair and maintenance pack ages. "When I price a contract, all I have to do is estimate the annual mileage and tyre wear and put in my own overheads. Everything else is costed out for me. For example, I know that our Leyland Daf FT 95.310 will cost £234 per month for all servicing, lubes, repairs and recovery. And I know that the fee is fixed for four years."

Derek, too, would never work in any other way. "We couldn't even entertain the idea of running our own workshop. It's just not worth the hassle, and you get so tied up in thinking about maintenance schedules that you can't think about ways to expand."

The Aulds bought four trucks last year for £150,000, bringing their fleet up to nine vehicles including a Roadrunner, two Ford Cargos, a Leyland Freighter for drawbar work, a Leyland 24-tonner, plus the 95.310, a Mercedes panel van and a Volvo shunter.

This year, expansion will be slower. "It's time to consolidate but we are looking to get into pharmaceuticals and cosmetics distribution. We already have enough staff here to grow without taking on more overheads."

Tracy's father Norman Wright oversees the day-to-day administration of the operation while brother Steven looks after the warehouse. Nine drivers, "all fantastic lads", complete the team.

"All Derek and I know is trucks," says Ken. "We were drivers from the age of 21 and our father John was a driver before us. We could not allow this thing to fail. Our houses were on the line. It was sink or swim."

by Paul Fisher

SAVE OUR LAYBYS

• Not content with forcing traditional transport cafes to close, county councils are now gunning for laybys (CM 20-26 September).

The number of places where drivers can take their statutory breaks are disappearing thick and fast.

How can the spokesman for Kent Council's highways department blame the closure of laybys on safety? Surely the fact that laybys exist gives all drivers, not just HGVs, the chance to pull off the road and take a rest.

Richard Rockford, Chertsey, Surrey.

ONE OF THE GOOD GUYS

• While I was pleased to read in Commercial Motor (13-19 September) that police are seeking to impose tougher penalties on foreign drivers who fail to supply tachograph charts, I did wonder why a vehicle carrying one of Huktra's tank containers should have been pictured being inspected by the police.

On reflection, of course, 1 realised that out of the hundreds of vehicles stopped for inspection that day your photographer chose our equipment because of its particular quality and exemplary standard of presentation.

The vehicle was in fact being driven by one of our most experienced drivers.

Two minutes later, it was given the "all clear" by the police and departed to deliver its load.

Huktra is an innovative company which seeks to ensure that its tank containers are of the highest standard.

In recent years, for exam Huktra has been responsible for the development of large 28,000-litre tank containers designed to ensure that higher payloads can be carried within the current UK weight restrictions.

Our policy is to insist that contractors maintain the vehicles conveying our tank containers in a first-class condition, and that tachograph requirements are strictly met. Peter Meyrick, Managing Director, Huktra (UK), Widnes, Cheshire.

Commercial Motor welcomes readers' letters, which can be phoned in on 081-661 3689 (24-hour service). Letters may be edited for length and do not necessarily represent the views of the editor.