• Leyland's Sherpa van is 22 years old, and has

Page 104

Page 105

Page 106

If you've noticed an error in this article please click here to report it so we can fix it.

had quite a few changes over the years though the basic design has remained much the same. To learn where the service differences are in the last few models and to find out where many operators make mistakes which cost them a lot of unnecessary money, we went to the commercial division of Catfyns in Ashford, Kent.

The policy of change on the Sherpa has been a gradual one rather than saving all the changes for a new model. For example. over the past few years there have been three types of gearbox rear mounting, the greasing points on the propshaft were first cut to one and then deleted altogether, the rear brakes now have automatic adjusters, and so on.

Another important change to bear in mind is that the five-speed gearboxes on Sherpas neither use a gear oil nor an engine oil. Though they are manual boxes they use automatice transmission fluid, and any introduction of other oils into them for topping up will, in the words of one of Caffyns' fitters: "gum up the whole shooting match."

The main service interval on the Sherpa is 20,000km (the Leyland book still quotes mileage, in this case 12,000) though there is a scheduled intermediate check at 10,000Iun (6,000 miles). Many operators neglect this check and sometimes Caffyns sees the vans belonging to some of its customers only once a year unless anything goes wrong. This is far too long an interval, and we have highlighted most of the points which need more frequent attention, if only to check them.

• by Peter Wallage

1 The kingpins on earlier

Sherpas had bronze thrust washers and bronze main bushes. If they are not treated to a dose of grease at more frequent intervals than once a year they tend to go stiff with consequent driver complaints. Later models, which take an oil gun rather than a grease gun, use needle rollers with much better sealing. The sealing is so good that sometimes when they are being lubricated the steering seems to go stiff But this is "hydraulic lock" and will disappear if the steering is worked back and forth a few times.

2 The latest Sherpas have telescopic dampers on the front, but earlier models had lever-arm-type dampers. These often gave trouble not mainly because they failed. though they did leak occasionally, but mainly because they were not kept topped up and the mounting bolts were not checked regularly. In some cases where the mounting bolts had come loose without the operator realising it, the holes in the chassis had become oval and Caffyns had to weld and re-drill — an unnecessary expense for want of attention with a spanner. 3.Vol many years ago the universal joints on the propshaji, and the sliding spline, needed regular lubrication. Then Leyland fitted sealed-for-life universals but

left one nipple for attention on the sliding spline. Now even this has been done away with and many operators forget that earlier models of the new look" Sherpas still have one lubrication point on the transmission. Another Point to keep an eye on is the centre propshaft bearing. This rubber bearing carries on for years but then can go quite suddenly without much warning, as here. Failure to catch it in time is another point of unnecessary expense.

4 Exhaust systems are expensive items these days, and the mild-steel sort have a short enough life without being helped on their way. One reason for premature failure

on the Sherpa could be that this clip on the double down pipe has either come loose of fallen away. It seems that the expansion and contraction from the heat of the pipe can weaken the holding bolt. Some operators have even been known to buy a new exhaust system and fit it without this clip because the original had fallen off and they did not realise it was necessary. Then they complained that the exhaust broke.

5 Still on the exhaust system, it pays to keep a regular eye, and a spanner, on the flange nuts where the down pipes meet the manifold. These can sometimes work loose and often when one downpipe works loose all the strain of holding the exhaust system at the front falls on the other one and it is not unknown for a stud to shear. The nuts are none too easy to get at with an ordinary spanner, but with a socket and long extension they can be reached reasonably easily underneath.

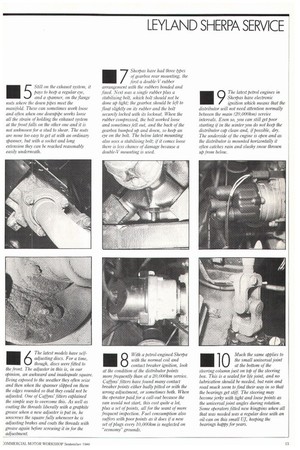

6 The latest models have selfadjusting discs. For a time, though, discs were fitted to the front. The adjuster in this is, in our opinion, an awkward and inadequate square. Being exposed to the weather they often seize and then when the spanner slipped on them the edges rounded so that they could not be adjusted. One of Caff5ms' fitters explained the simple way to overcome this. As well as coating the threads liberally with a graphite grease when a new adjuster is put in, he unscrews the square fully whenever he is adjusting brakes and coats the threads with grease again before screwing it in for the adjustment. 7 Sherpas have had three types of gearbox rear mounting, the first a double-V rubber arrangement with the rubbers bonded and fixed. Next was a single rubber plus a stabilising bolt, which bolt should not be done up tight; the gearbox should be left to float slightly on its rubber and the bolt securely locked with its locknut When the rubber compressed, the bolt worked loose and sometimes fell out, and the back of the gearbox bumped up and down, so keep an eye on the bolt. The below latest mounting also uses a stabilising bolt; if it comes loose there is less chance of damage because a double-V mounting is used.

8 With a Petrol-engined Sherpa with the normal coil and contact breaker ignition, look at the condition of the distributor points more frequently than at a 20,000km service. Caffyns' fitters have found many contact breaker Points either badly Pitted or with the wrong adjustment, or sometimes both. When the operator paid for a call-out because the van would not start, this cost quite a lot, plus a set of points, all for the want of more frequent inspection. Fuel consumption also suffers with poor points as it does i f a new set of Plugs every 10,000km is neglected on "economy" grounds. 9 The latest petrol engines in Sherpas have electronic ignition which means that the distributor will not need attention normally between the main (20,000km) service intervals. Even so, you can still get poor starting if in the winter you do not keep the distributor cap clean and, if possible, dry. The underside of the engine is open and as the distributor is mounted horizontally it often catches rain and slushy snow thrown up from below.

1 0 Much the same applies to the small universal joint at the bottom of the steering column just on top of the steering box, This is a sealed for life joint, and no lubrication should be needed, but rain and road muck seem to find their way in so that the bearings get stiff The steering may become jerky with tight and loose points as the universal joint angles during rotation. Some operators fitted new kingpins when all that was needed was a regular dose with an oil-can on this small Uj, keeping the bearings happy for years. M1 1 Different crankcase breathing arrangements on She as are caused partly by changed engines and also by EEC regulations insisting that an engine eats its own fumes. For a time during the 19 70s the oil filler-cum-breather was a sealed filter which had to be renewed at least every 38,000km (24,000 miles) and preferably at half that figure on older engines to avoid back pressure. The later 0-series petrol engines have a different breathing arrangement with no oil filler on the camshaft cover; on the larger diesels the filler cap is still the breather, a cleanable type rather than a throwaway type, needing a wash out at 20,000km intervals.

1 Caffyns' fitters have found numerous examples of complaints about poor running, poor acceleration and stalling at traffic lights due to the simple fault that the dashpot damping was dry. It does not last for 20,000km without at least giving symptoms of poor running. Another little point which is overlooked is that the small rubber elbow piece to the right of the dashpot here, and which carries the automatic advance and retard line gets loose and sometimes comes off if oil spillage from topping up the dashpot has made the rubber soggy. 1 sTihmisplie's nawsdnifiaicl al taionnd which CaftYns has made to its own service pick-up Sherpa. Normally, there is no need for an extra filter in the petrol feedline. but on the Calblis pick-up the tank developed some internal rust which was coming through and blocking the pump. This small plastic line filter, which is a standard Range Rover part, was fitted after draining and flushing the tank to take care of any remaining rust particles. It just pushes into the ends of the plastic feedline. The amount of rust dust it has trapped th a month or Iwo has made the modification well worthwhile.

On the 1,800cc diesel engine, the fuel-lift pump looks very similar to a normal AC --Npe petrol pump but as well as having a filter in it, it also has a water trap. Though it is a little awkward to get at, it Pays to investigate this should the engine give signs of bad fuel flow or spluttering. The ring attached to the small lever underneath is the usual arrangement for sucking up fuel from the tank manually to avoid lengthy cranking over on the starter should the fuel system have been disturbed for any reason.

14

5 1 Operators who have changed over to a diesel engine may not realise the importance of changing the main file' filter at the recommended intervals and the importance of clean derv. Some of the filters are left in far too long. There is a second water trap in the fuel system of the 1,800cc diesel which many owners overlook. Hidden away at the base of the main fuel filter is a small wing plug which should be released to drain out any water at regular intervals. In weather conditions which give rise to condensation inside the tank it is surprising how much water can collect in the bottom of the filter between the intervals when it should be renewed.

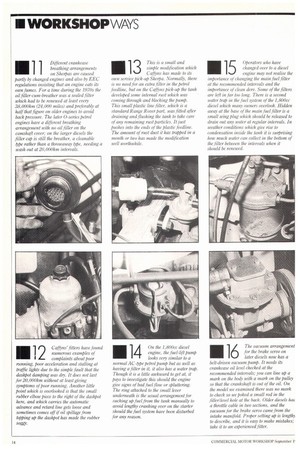

The vacuum arrangement for the brake servo on later diesels now has a belt-driven vacuum pump. It needs its crankcase oil level checked at the recommended intervals; you can line up a mark on the body with a mark on the pulley so that the crankshaft is out of the oil. On the model we examined there was no mark to check so we poked a small rod in the fillertlevel hole at the back Older diesels &lc a throttle cable in two sections, and the vacuum for the brake servo came from the intake manifold. Proper setting up is lengthy to describe, and it is easy to make mistakes; take it to an experienced fitter.

16