UNIQUE E NE IN

Page 34

Page 35

Page 36

If you've noticed an error in this article please click here to report it so we can fix it.

NEW TROJAN Pressure Lubrication in and a Distributor Co;

.rtvo stroke Unit in Which Charger Cylinders fix re Delivery : Steel Plate Employed in led Fabricated Frame

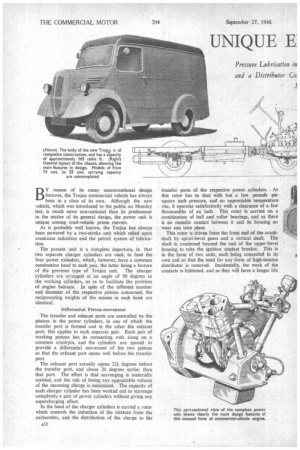

BY reason of its many unconventional design features, the Trojan commercial vehicle has always been in a class of its own. Although the new vehicle, which was introduced to the public on Monday last, is much more conventional than its predecessor in the matter of its general design, the power unit is unique among road-vehicle prime movers.

As is probably well known, the Trojan has always been powered by a two-stroke unit which relied upon crankcase induction and the petrol' system of lubrication.

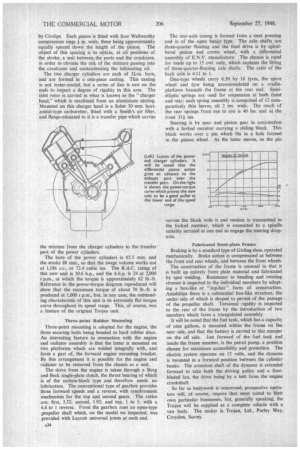

The present unit is a complete departure, in that two separate charger cylinders are used, to feed the four power cylinders, which, however, have a common combustion head to each pair, the latter being a feature of the previous type of Trojan unit. The charger cylinders are arranged at an angle of 90 degrees to the working cylinders, so as to facilitate the problem of engine balance. In spite of the different number and diameter of the respective pistons concerned, the reciprocating weights of the masses in each bank are identical.

Differential_ Piston-movement

The transfer and exhaust ports are controlled by the pistons in the power cylinders, in one of which the transfer port is formed and in the other the exhaust port; this applies to each separate pair. Each pair of working pistons has its connecting rods slung on a common crankpin, and the cylinders are spaced to provide a differential movement of the two pistons so that the exhaust port opens well before the transfer Port The exhaust port actually opens 221 degrees before the transfer port, and closes 20 degrees earlier than that port. The effect is that scavenging is materially assisted, and the risk of losing any appreciable volume of the incoming charge is minimized. The capacity of each charger cylinder has been worked out to scavenge completely a pair of power cylinders without giving any supercharging effect.

In the head of the charger cylinders is carried a rotor which controls the induction of the mixture from the carburetter, and the distribution of the charge to the transfer ports of the respective power cylinders. As this rotor has to deal with but a few pounds per square inch pressure, and no appreciable temperature rise, it operates satisfactorily with a clearance of a few thousandths of an inch. This rotor is carried on a combination of ball and roller bearings, and as there is no metallic contact between it and its housing no wear can take place.

This rotor is driven from the front end of the crankshaft by spiral-bevel gears and a vertical shaft. The shaft is continued beyond the end of the upper-bevel housing to take the ignition contact breaker. This is in the form of two units, each being connected to its own coil so that the need for any form of high-tension distributor is removed. Incidentally, the work of the contacts is lightened_ and as they will have a longer life

in consequence, the need for adjustment becomes less frequent.

Particular attention has been devoted to the lubrication system, in which the oil is picked up and circulated by a gear-type pump, driven from the lower end of the shaft which drives the inlet rotor. This pump, which feeds oil to the main and big-end bearings at approximately 38 lb. per sq. in. at normal engine speed, has a capacity of 50 gallons per hour at 1,000 r.p.m. of the engine. There is a full-flow Purolator filter built into the crankcase, and it is to be noted that there is only one short, external oil pipe.

So far as general details of this new unit are concerned, the power-cylinder bank is a monobloc casting having a detachable head, incorporating, as previously mentioned, a common combustion chamber for each pair of power cylinders. Whilst the crankcase is in aluminium, the oil sump, having a capacity of approximately 7 pints, is made of steel. A carbon-steel forging is used for the crankshaft, which is carried in two main bearings of 2.397-in, diameter; the crankpins are 2.125 ins, in diameter.

Manganese-molybdenum-steel stampings are employed for the connecting rods, of which there are three on each crankpin. The centre one of the three, which drives a charger piston, is clamped to a phosphor-bronze intermediate sleeve running the full width of the crankpin, and lined with Vandervell bearings. The two rods carrying the power pistons, one mounted on each side of the charger connecting rod, are free to oscillate on the outside of the intermediate sleeve, which is drilled in the area of the big-ends for lubrication purposes.

Cast iron is used for the power pistons, the floating gudgeon pins in which are I-in. diameter and located by Circlips. Each piston is fitted with four Wellworthy compression rings in. wide, these being approximately equally spaced down the length of the Piston. The object of this spacing is to obtain, at all positions of the stroke, a seal between, the ports and the crankcase, in order to obviate the risk of the mixture passing into the crankcase and contaminating the lubricating oil.

The two charger cylinders are each of 31-in, bore, and are formed in a one-piece casting. This casting is not water-cooled, but a series of fins is cast on the ends to impart a degree of rigidity in this area. The inlet rotor is carried in what is known as the "charger head," which is machined from an aluminium casting. Mounted on this charger head is a Solex 30 mm. horizontal-type carburetter, fitted with a Smith's air filter, and flange-mounted to it is a transfer pipe which carries the mixture from the charger cylinders to the transfer port of the power cylinders.

The bore of the power cylinders is 65.5 mm. and the stroke 88 mm., so that the swept volume works out at 1,186 c.c., or 72.4 cubic ins. The R.A.C. rating of this new unit is 10.6 h.p., and the b.h.p. is 24 at 2,000 r.p.m., at which the torque is approximately 62 lb.-ft. Reference to the power-torque diagram reproduced will show that the maximum torque of about 70 lb.-ft. is produced at 1,000 r.p.m., but, in any case, the outstanding characteristic of this unit is its extremely flat torque curve throughout its speed range. This, of course, was a feature of the original Trojan unit.

Three-point Rubber Mounting

Three-point mounting is adopted for the engine, the three securing bolts being bonded to hard rubber discs. An interesting feature in connection with the engine and radiator assembly is that the latter is mounted on two platforms which are welded integrally with, and form a part of, the forward engine mounting bracket. By this arrangement it is possible for the engine and radiator to be removed from the chassis as a unit.

The drive from the engine is taken through a Borg and Beck single-plate clutch, the thrust bearing of which is of the carbon-block type and therefore needs no lubrication. The conventional type of gearbox provides three forward speeds and a reverse, with synchromesh mechanism for the top and second gears. The ratios .are: first, 3.52; second, 1.92; and top, 1 to 1; with a 4.4 to 1 reverse. From the gearbox runs an open-type propeller shaft which, on the model we inspected, was provided with Layrub universal joints at each end. The rear-axle casing is formed from a steel pressing and is of the open banjo type. The axle shafts• are three-quarter floating and the final drive is by spiralbevel pinion and crown wheel, with a differential assembly of E.N.V. manufacture. The chassis is rated for loads up to 15 cwt. only, which explains the fitting of three-quarter-floating axle shafts. The ratio of the back axle is 4.11 to I.

Disc-type wheels carry 6.50 by 16 tyres, the spare• wheel and tyre being accommodated on a cradleplatform beneath the frame at the rear end. Semielliptic springs are used for suspension at both front and rear; each spring assembly is comprised of 12 comparatively thin leaves, all 2 ins. wide. The reach of the rear springs from eye to eye is 40 ins, and at the front 311 ins.

Steering is by spur and pinion gear in conjunction with a forked member carrying a sliding block. This block works over a pin which fits in a hole formed in the pinion wheel. As the latter moves, so the pin carries the block with it and motion is transmitted to the forked member, which is connected to a spindle suitably serrated at one end to engage the steering droparm.

Fabricated Steel-plate Frame Braking is by a standard type of Girling shoe, operated mechanically. Brake action is compensated as between the front and rear wheels, and between the front wheels.

The construction of the frame is unusual in that it is built up entirely from plate material and fabricated by spot welding. Resistance to bending and twisting stresses is imparted to the individual members by adopting a box-like or " top-hat " form of construction. Amidships there is a substantial box-like structure, the under side of which is shaped to permit of the passage of the propeller shaft. Torsional rigidity is imparted to the rear of the frame by the introduction of two members which form a triangulated assembly.

It will be noted that the fuel tank, which has a capacity of nine gallons, is mounted within the frame on the near side, and that the battery is carried in like manner on the off side. Just forward of the fuel tank and inside the frame member, is the petrol pump, a position chosen for maximum accessibility and protection. The electric system operates on 12 volts, and the dynamo is mounted in a forward position between the cylinder banks. The armature shaft of the dynamo is extended forward to take both the driving pulley and a fourbladed fan, the drive being by a belt from the engine crankshaft.

So far as bodywork is concerned, prospective operators will, of course, require that most suited to their • oWn particular businesses, but, generally speaking, the Trojan will be supplied as a complete vehicle with a van body. The maker is Trojan, Ltd,, Purley Way, • Croydon, Surrey.