ROADSIDE AND GARAGE.

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

A Page for Drivers, Mechanics and Foremen.

Some Garage Toots.

The sender oft& following communication has been awarded the extra payment of 6s. this week.

(2292) " T.R.W." (Wigan) writes:— " I do not think anyone will dispute the utility of the tools which are illustrated in the accompanying sketches, and to which the following descriptions apply. I put them forward as being suitable for publication on your Roadside and Garage' page, and believe that their chief claim for consideration lies in their simplicity of construction.

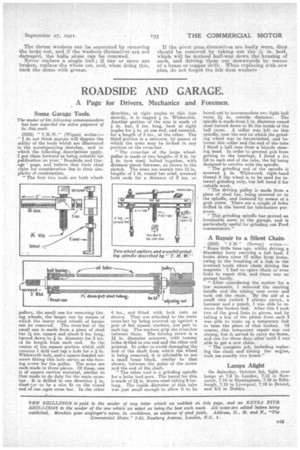

" The first two tools are both wheel

pullers; the small one for removing timing wheels, the larger one by means of which the heavy road_ wheels of lorries can be removed. The cross-bar of the email one is made from a piece of steel bar 11 ins, square and about 8 ins, long, turned down to in. diameter for 3 ins. of its length from each end. In the centre of thesquare portion which still remains I drill and tap a' hole for a I in. Whitworth bolt, and a square-headed set. screw fitting this hole serves as the forcing screw for the puller. The arms are each made in three pieces. Of these, one is of square section material, similar to that made to do duty for the main cross bar., It is drilled in one direction in. dianiater to be a nice fit on the round end of taleaniain cross bar. In the other a ,

direction, at right angles to this (see sketch), it is tapped in. Whitworth. Another portion of the arm is made of in. bar, 5 ins, long, bent at right angles for in. at one end, and screwed, for a length of 3 ins., at the other. The third portion is a setscrew, by means of which the arms may be locked in any position oil the cress-bar.

"The cross-bar of the large wheelpuller is. made of two lengths of 2 in. by g in. tyre steel, bolted together, with distance pieces between, as shown in the sketch. The arras are merely two 15 in. lengths of 1 in. round bar steel, screwed bath ends for a distance of 3 ins. or 4 ins., and fitted with lock nuts as shown. They are attached to the main cross-bar by being screwed up against a pair of flat square washers, one pair to each leg. The washers grip the cross-bar between them. The forcing screw is a 11 in. diameter setscrew, with tommy holes drilled in one end and the other end pointed. In order to avoid damaging the end of the shaft from which the wheel is being removed, it is advisable to use a small brass block, similar to that shown, between the point of the screw and the end of the. shaft.

"The other. tool is a grinding spindle for a lathe tool. post. The barrel for this is made of 11 in, drawn steel tubing 9 ins. long. The inside diameter of this tube was .just small enough to allow it to be

bored out to acconunodate two light ball races 4 in. outside diameter. The spindle is made from 1 in. diameter round steel turned down to fit the inside of the ball races. A collar was left on this spindle, near the end oft which the grinding wheel was to betmounted, and between this collar and the end of the tube I fitted a ball race from a bicycle steering head. In order to prevent grit from getting to the bearings, I fitted a tin lid to each end of the tube, the lid being designed to revolve with the spindle. "The grinding end of the spindle is

screwed in. Whitworth right-handthread if the wheel, is to be used for internal grinding only, but left hand if for outside work.

"The driving pulley is made from a piece of steel bar, being screwed on to the spindle, and fastened by means of a grub screw. There are a couple of holes drilled in the barrel for lubrication purposes.

"This -grinding spindle has proved an invaluable asset to the garage, and is particularly useful for grinding out Ford commutators."

A Repair to a Silent Chain.

(2293) `` (Newsy) writes :— " Some little time ago, whilst driving a Maui:Islay lorry carrying a full load, I brake down some 15 mites from 'home, owing to the breaking of a link in the inverted tooth silent chain driving the magneto. I had no -spare chain or even links to repair this,and there. was no garage handy.

" After considering the matter for a few moments, I removed the starting handle and the timing case cover and took out the chain. By the aid of a small vice (which I always carry), a hammer and a punch, I was able to remove the broken link. After this I took two of the good links to pieces, and by taking a few of the plates from_ each I was able to make up a temporary link to take the place of that broken. Of course, this temporary repair was not strong, but it served to carry me home, and ran for three clays after unlit I was able to get a new chain.

" The complete job, including replac• ing the chain and timing the engine, took me exactly two hours."

Lamps Alight On Saturday, -October 1st, light your lamps at 7.8 in London, 7.12 in Newcastle, 7.14 in Birmingham, 7-18 in -Minburgh, 7.19 in Liverpool, 7.18 in Bristol, and 8.2 in Dublin.