A 4-ton Lorry for Schweppes, Limited.

Page 24

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

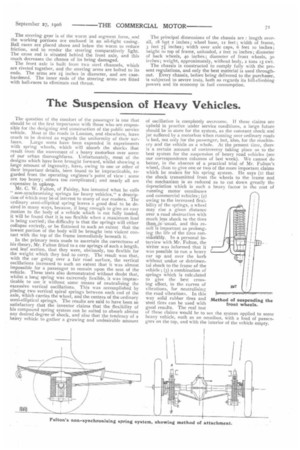

The illustrations which appear on this page are those of a side view and of details of the engine generally of the wagon built by the Brush Electrical Engineering Company, Limited, of Falcon Works, Loughborough, to the order of Schweppes. the well-known mineral water manufacturers.

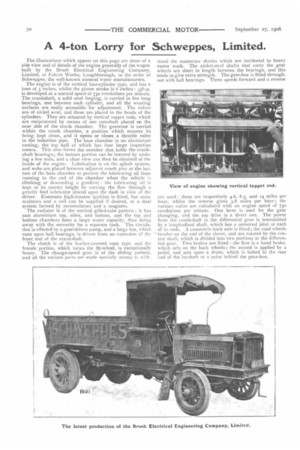

The engine is of the vertical four-cylinder type, and has a bore of 5 inches, whilst the piston stroke is 6 inches : 35h.p. is developed at a normal speed of 750 revolutions per minute. The crankshaft, a solid steel forging, is carried in five long bearings, one between each cylinder, and all the wearing surfaces are easily accessible for adjustment. The valves are of nickel steel, and these are placed in the heads of the cylinders. They are actuated by vertical tappet rods, which are reciprocated by means of one camshaft placed on the near side of the crank chamber. The governor is carried within the crank chamber, a position which ensures its being kept clean, and it opens or closes a throttle valve in the induction pipe. The base chamber is an aluminium casting, the top half of which has four large inspection covers. This also forms the member that holds the crankshaft bearings; the bottom portion can be lowered by undoing a few nuts, and a clear view can then be obtained of the inside of the engine. Lubrication is on the splash system, and webs are placed between adjacent crank pins at the bottom of the base chamber to prevent the lubricating oil front running to the end of the chamber when the vehicle i. climbing or descending a gradient : the lubricating oil is kept at its correct height by varying the flow through a gravity feed lubricator placed upon the dash in view of the driver. Eisemann high-tension ignition is fitted, but accuniulators and a coil can be supplied if desired, or a dual system formed by accumulators and a magneto.

The radiator is of the vertical gilled-tube pattern : it has east aluminium top, sides, and bottom, and the top and bottom chambers have a large water capacity, thus doing sway with the necessity for a separate tank. The circulation is effected by a gear-driven pump, and a large fan, which runs upon ball bearings, is driven from an extension of the front end of the crankshaft.

The clutch is of the leather-covered cone type, and the female portion, which forms the fly-wheel, is exceptionally heavy. The change-speed gear is of the sliding pattern, and all the various parts are made specially strong to with

stand the numerous shocks which are incidental to heavy motor work. The nickel-steel shafts that carry the gear wheels are short in length between the bearings, and this tends to give extra strength. The gear-box is fitted throughout with ball bearings. Three speeds forward and a reverse

are used : these are respectively 4.6, 8.5, and 14 miles per hour, whilst the reverse gives 3.8 miles per hour; the various ratios are calculated with an engine speed of 750 revolutions per minute. One lever is used for the gear changing, and the top drive is a direct one. The power from the crankshaft to the differential gear is transmitted by a longitudinal shaft, which has a universal joint at each of its ends. A concentric back axle is fitted; the road wheels —revolve on the end of the sleeve, and are rotated by the central shaft, which is divided into two portions at the differential gear. Two brakes are fitted : the first is a hand brake, which acts on the back wheels; the second is applied by a pedal, and acts upon a drum, which is bolted to the rear end of the lavhaft at a point behind the gear-box.

The steering gear is of the worm and segment form, and the working portions are enclosed in an oil-tight casing. Ball races are placed above and below the worm to reduce friction, and to render the steering comparatively light. The cross rod is situated behind the front axle, and this much decreases the chance of its being damaged. The front axle is built from two steel channels, which are riveted together, and the steering arms are bolted to its ends. The arms are 2i inches in diameter, and are casehardened. The inner ends of the steering arms are fitted with ball-races to eliminate end thrust.

The principal dimensions of the chassis are : length overall, 18 feet a inches; wheel base, 72 feet ; width of frame, 3 feet 7 inches; width over axle caps, 6 feet io inches; height to top of frame, unloaded, 2 feet io inches; diameter of back wheels, 40 inches; diameter of front wheels, 30 inches; weight, approximately, without body, 2 tons is cwt.

The chassis is constructed to comply fully with the present regulations, and only the best material is used throughout. Every chassis, before being delivered to the purchaser, is subjected to severe tests, both as regards its hill-climbing powers and its economy in fuel consumption.