Features of the New Hercules Chassis.

Page 15

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

A Novel and Patented Method of Gear Adjustment.

A representative of this journal was afforded an opportunity last week to make a careful examination of the latest production of the Hercules Works, at Chapel Street, Levenshulme, near Manchester, when various special features a the system were pointed out to him. Many of our readers will recollect different references to the manufactures of the Hercules Company, which have appeared in our issues during the last few months, but it has not previously been possible for anybody to make a detailed inspection of the chassis to which we now have to refer. The -partidulars _given in this short descriptive article can be supplemented, if desired, by reference to our issue of March 8th last.

The powerful vertical engine has four cylinders, each 41 inches in diameter, and a piston stroke of 6 inches : it gives 4ob.h.p. when run at 970 revolutions per minute, although the gear ratios of the vehicle are based upon a normal speed some iso revolutions less than this. Four rings are employed upon each of the pistons, which are truly balanced, whilst the connecting rods are solid-forged from mild steel, and most carefully finished within a very small limit of weight variation. Both inlet and exhaust valves are mechanically operated from separate camshafts, one placed on each side of the crank chamber, and disposed in oil-retaining covers. Lubrication is by a belt-driven Doherty lubricator, which is arranged with three principal delivery pipes : one of these is sub-divided to supply the pistons and crank bearings; the other two are separately carried to the base of each crank chamber. There is, in addition, a hand pump on the lubricator box, which enables the driver occasionally to force extra oil, along the connecting pipes of the automatic couplings, to the pistons and crank bearings. The drips for the automatic lubricator are on the dashboard, immediately under the eye of the driver. Low-tension magneto is fitted, with the usual accumulators and coil in reserve. The radiator is of large size, and arranged for easy cleaning : its framework consists of light steel castings.

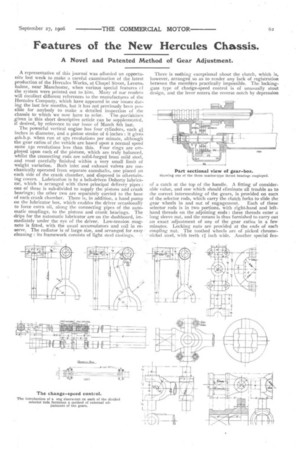

There is nothing exceptional about the clutch, which is, however, arranged. so as to render any lack of registration between the members practically impossible. The lockinggate type of change-speed control is of unusually stout design, and the lever enters the reverse notch by depression

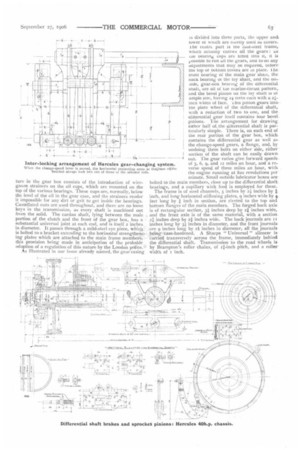

of a catch at the top of the handle. A fitting of considerable value, and one which should eliminate all trouble as to the correct intermeshing of the gears, is provided on eacn of the selector rods, which carry the clutch forks to slide the gear wheels in and out of engagement. Each of these selector rods is in two portions, with right-hand and lefthand threads on the adjoining ends : these threads enter a i long sleeve nut, and the means s thus furnished to carry out an exact adjustment of any of the gear ratios in a few minutes. Locking nuts are provided at the ends of each coupling nut. The toothed wheels are of picked chromenickel steel, with teeth II inch wide. Another special fea

ture in the gear box consists of the introduction of wiregauze strainers on the oil cups, which are mounted on the top of the various bearings. These cups are, normally, below the level of the oil in the gear case, and the strainers tender it impossible for any dirt or grit to get inside the bearings. Castellated nuts are used throughout, and there are no loose keys in the transmission, as every shaft is machined out from the solid. The cardan shaft, lying between the male portion of the clutch and the front of the gear box, has a substantial universal joint at each, end, and is itself 2 inches in diameter, It passes through a mild-steel eye piece, which is bolted to a bracket extending to the horizontal strengthen. ing plates which are attached to the main frame members, this provision being made in anticipation of the probable adoption of a regulation of this nature by the London police.

As illustrated in our issue already named, the gear casing

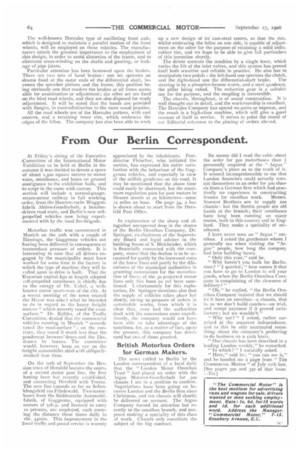

divided into three parts, the upper an tower ot winch are niereiy used as covers. ihe centre, part is the cast-steel frame, winch. actually carries all the gears : as CAC nearing caps are nttect into it, It is possible to run all the gears, and to do any aajustments that may oe required, eefore the Lop or bottom covers are in piaCe. /he. 'runt bearing of the main gear shalt, the clack bearing ot the lay shalt, and the oil— side, gear-oox bearing of the ninerential snalt, are all of Lae marine-thrust pattern,. and the bevel pinion on toe lay shalt is eat ample size, having 24 teetn each with a 2*men widtn of face. ..ehis pinion gears into toe plate wheel of the dilierential shaft, with a reduction of two to one, and the differential gear itself contains tour bevel. pinions. Inc arrangement for drawing either half of, the dilterential shaft is particularly simple. '1 here is, on each end of the rear portion of the gear box, which. contains the differential gear as well as the change-speed gears, a flange, and, by undoing three bolts on either side, either• section of the shaft can be easily drawn out. The gear ratios give forward speeds. of 3, 6, 9, and 12 miles an hour, and a reverse speed of three miles an hour, with, the engine running at 820 revolutions per minute. Small outside lubricator boxes arebolted to the main members, close up to the differential shaft. bearings, and a capillary wick feed is employed for these. The frame is of steel channels, 5 inches by 2* inches by I_ inch, and long horizontal stiffening plates, 9 inches wide by 4. feet long by I inch in section, are riveted to the top and bottom flanges of the main members. The forged back axle is of rectangular section, 3* inches deep by 2f inches wide, and the front axle is of the same material, with a section. 21 inches deep by 2/ inches wide. The back journals are it inches long by 3* inches in diameter, and the front journals are 9 inches long by 2i inches in diameter; all the journals being case-hardened, A Sharpe " Universal " silencer is carried transversely across the frame, immediately behind the differential shaft. Transmission to the road wheels isby Brampton's roller chains, of if-inch pitch, and a roller. width of I inch. --- The well-known Hercules type of oscillating front axle, -which is designed to maintain a parallel motion of the front wheels, will be employed on these vehicles. The manufacturers attach the greatest importance to the employment of this design, in order to avoid, distortion of the frame, and to 'eliminate cross-winding on the shafts and gearing, or leakage of pipe joints.

Particular attention has been bestowed upon the brakes. There are two sets of band brakes : one set operates on ;drums fixed at the outer ends of the differential shaft, between the sprocket pinions and the frame, this position being obviously one that renders the brakes at all times accessible for examination or adjustment ; the other set are fixed -on the hind road wheels, and they are also disposed for ready adjustment. It will be noted that the bands are provided with flanges, in contradistinction to the more usual practice.

All the road wheels are of the Hercules pattern, with cast centres, and a retaining inner rim, which embraces the .edges of the felloe. The company has also been able to work up a new design of its cast-steel centre, so that the rim, whilst embracing the felloe on one side, is capable of adjustment on the other for the purpose of retaining a solid indiarubber tire, and we hope to be able to give full particulars of this invention shortly. The driver controls the machine by a single lever, which varies the lift of the inlet valves, and this system has proved itself both sensitive and reliable in practice. He also has to manipulate two pedals : the left-hand one operates the clutch, and the right-hand one the differential-shaft brake. The steering is by a phosphor-bronze worm, and a steel quadrant, the pillar being raked. The reduction gear is a suitable one for the purpose, and the coupling is irreversible. The chassis, throughout, is of sound construction. It is well thought out in detail, and the workmanship is excellent. The Hercules Company has spared no pains or expense, and the result is a high-class machine, which will give a good account of itself in service. It serves to point the moral of our Editorial reference to the placing of orders abroad.