Loosing the thread

Page 62

Page 63

If you've noticed an error in this article please click here to report it so we can fix it.

Stripping a thread, says Peter Watt, need not be a cause for panic. One of the established thread repair kits can come to the rescue

in Like the car that decides not to start just when you are in a hurry to get to the airport, stripped threads have a tendency to occur precisely when you do not want them to. When they do, however, what you need is a quick, easy and reliable way of repairing the thread to allow you to get OD with the job.

Going under the generic name of HeliCoil, thread repair kits have been available for many years now, and are an essential part of the stores in any busy workshop. Although there are some differences, these kits are based on the same general principle. Firstly the stripped or damaged thread is removed, then the resulting hole is tapped, and finally an insert is put in, with the inner surface of the insert forming the new thread at the original diameter.

Thread repair kits cannot be considered as a cure-all, however, and are best seen as an emergency solution which gets you out of an awkward problem. Their effectiveness will depend to a great deal on the care taken in their use, and the appropriateness of using such a repair in the chosen application. When done properly, though, the repair should give no cause for concern in the future.

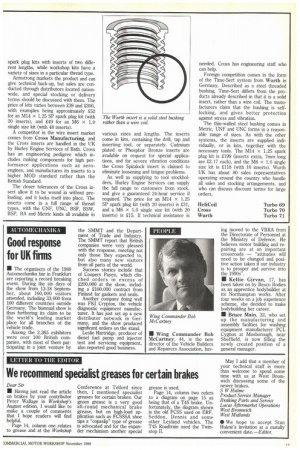

The first rule in using thread repair kits must be to follow the guidelines laid down by the manufacturer. This includes using the special tools available, and only using the kits on materials and in places to which they are suited. When drilling and tapping, alignment is all-important, and if the repair is carried out in situ, keeping swarf from reaching moving parts is of vital importance. If investment in the proper tools is difficult to justify, a simple solution is to make contact with a local specialist to do the job for you.

The original HeliCoil is made by Armstrong Fastening Systems inHull. It is the classic kind of wire insert, manufactured to the appropriate British Standard, and the makers claim that the inserts are resistant to stripping, galling and corrosion,; and will not seize under high temperature. On the market for over 30 years, the HeliCoil inserts are available in what is probably the largest range of sizes, with over 4,000 variations on the books. If the order is large enough, Armstrong will even produce a special size to order.

HeliCoil is more typically supplied in kit form, complete with the tap, inserting tool, inserts and full instructions. Kits are available in UNF, UNC, BSF, BSW, BSPF, BA and Metric sizes, with inserts of a standard length (11/2 x diameter) unless otherwise stated. There are special spark plug kits with inserts of two different lengths, while workshop kits have a variety of sizes in a particular thread type.

Armstrong markets the product and can give technical back-up, but sales are conducted through distributors located nationwide, and special stocking or delivery terms should be discussed with them. The price of kits varies between £39 and £300, with examples being approximately £52 for an M14 x 1.25 SP spark plug kit (with 20 inserts), and £49 for an M6 x 1.0 single size kit (with 48 inserts).

A competitor in the wire insert market comes from Cross Manufacturing, and the Cross inserts are handled in the UK by Hurley Engine Services of Bath. Cross has an engineering pedigree which includes making components for high performance applications such as aeroengines, and manufactures its inserts to a higher MOD standard rather than the British Standard.

The closer tolerances of the Cross insert allow it to be wound in without preloading, and it locks itself into place. The inserts come in a full range of thread types, with the UNF, UNC, BSF, BSW, BSP, BA and Metric kinds all available in various sizes and lengths. The inserts come in kits, containing the drill, tap and inserting tool, or separately. Cadmium plated or Phosphor Bronze inserts are available on request for special applications, and for severe vibration conditions the Cross Spiralock insert is claimed to eliminate loosening and fatigue problems.

As well as supplying to tool stockholders, Hurley Engine Services can supply the full range to customers from stock, and give a guaranteed 24-hour service if required. The price for an M14 x 1.25 SP spark plug kit (with 20 inserts) is 231, and a M6 x 1.0 single size kit (with 20 inserts) is £15. If technical assistance is needed, Cross has engineering staff who can help.

Foreign competition comes in the form of the Time-Sert system from Wurth in Germany. Described as a steel threaded bushing, Time-Sert differs from the products already described in that it is a solid insert, rather than a wire coil. The manufacturers claim that the bushing is selflocking, and gives better protection against stress and vibration.

The thin-walled steel bushing comes in Metric, UNF and UNC forms in a reasonable range of sizes. As with the other systems, the inserts are supplied individually, or in kits, together with the necessary tools. The M14 x 1.25 spark plug kit is £199 (inserts extra, 7mm long are £2.17 each), and the M6 x 1.0 single size kit is £118 (with 10 inserts). Wurth UK has about 80 sales representatives operating around the country who handle all sales and stocking arrangements, and who can discuss discount terms for large orders.