Leaner body display

Page 40

Page 41

Page 42

If you've noticed an error in this article please click here to report it so we can fix it.

MANY prominent body and trailer manufacturers who attended the previous Motor Show were conspicuous by their absence this year, deterred no doubt by the increased cost of mounting a display at the NEC.

This provoked a warning from Craven Tasker sales director John Hope "that with fewer major companies exhibiting, less specialist visitors would be attracted and, for the rest of us, the show would just die".

Several large companies exhibiting were alarmed by the expense, feeling that the commercial vehicle industry should have its own separate exhibition.

But many producers demonstrated that costs could be reduced by either trimming displays or combining their products on one stand.

Knowing the importance of overall payloads, body and trailer builders have pared excess weight where possible and changed designs to accommodate more metric pallets. Access has improved and more air suspensions were evident.

Although road tankers are only a small sector of the trailer market, they are highly specialised products, built to stringent regulations. Perhaps the fact that only two of the five tanker companies exhibiting were British, illustrates the sales success of the importers among UK companies with European operations.

Above: There were two drawbarmounted Spacemaster bodies on show, one a steel chassis version for Devonish Breweries on the Ray Smith stand, while this one for Peterborough Co-op had an aluminium chassis.

Don-Bur's design ensures an internal width of 2.45m (96.5in) sufficient to carry metric pallets side by side. Doors fold out and pass each other on a track which also forms a part of the structure and helps prevent excessive flexing.

Dunlop's Flexolink air suspension is used on the Co-op's trailer with a Jost HE78 turntable and VBG drawbar equipment. Above: Besco's insulated 7.3m (24h) body, mounted on a Leyland Freighter 76.15 chassis, typified the Euro wall design which achieved the 2.44m (96in) internal width necessary to carry metric pallets side by side.

Doors, which open outwards before sliding on the top track, are of 30mm (1.21n) grp sandwich ply construction. Provision is made for a refrigeration unit in the bulkhead.

With a body weight of 2 tonnes on a 5-tonne chassis, payloads of around 9 tonnes can be achieved.

Above left: Boaffoy showed its own 45,000Btulh demountable refrigerator unit designed to keep a full-size lnsuliner cargo at zero even in ambient temperatures as high as 30°C. Power for the allelectric system is from a generator driven by a 1.6-litre VAG Goff diesel engine.

By using an electrically-driven semi-hermetic motor compressor, Boa/Joy claims to have overcome the problem of refrigerant loss through shaft seals of conventional engine-driven compressors.

Left: Like other bodybuilders Lawrence David has realised the need to develop bodies that can accommodate two rows of metric pallets hence this Slidax flush sided sliding door design. With a 12.2m NOW semi-trailer, 24 pallet stacks can be contained.

The door mounting system allows the end doors to pull out and pass the three inner ones.

Price of a fully insulated 12.2m version less refrigeration unit is around £17,000. Above: Magyar SA of Dijon. France, has been building stainless steel semi-trailer tankers for almost 20 years. One example at the NEC was designed for carrying hazardous goods under ADR regulations.

Unusual features include the mounting of the semi-trailer's air line and electrical connections into the tank's front dome plus a twinoutlet manifold with sampler.

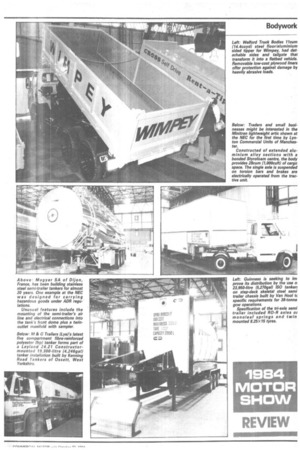

Below: M & G Trailers (Lye)'s latest five compartment fibre-reinforced polyester (frpi tanker forms part of a Leyland 24.21 Constructormounted 19,300-litre (4,246ga1) tanker installation built by Kenning Road Tankers of Ossett, West Yorkshire. Left: We/ford Truck Bodies 17cum (14.4cuyd) steel floor/aluminium sided tipper for Wimpey, had detachable sides and tailgate thai transform it into a flatbed vehicle. Removable low-cost plywood liners offer protection against damage by heavily abrasive loads.

Below: Traders and small businesses might be interested in the Minitran lightweight artic shown at the NEC for the first time by Lynton Commercial Units of Manchester.

Constructed of extended aluminium alloy sections with a bonded Styrofoam centre, the body provides 28cum (1,000cuft) of cargo space. The single axle is suspended on torsion bars and brakes are electrically operated from the tractive unit.

Left: Guinness is seeking to im prove its distribution by the use cc 23,950-litre (5,270gal) 1S0 tanker: on step-deck skeletal steel semi trailer chassis built by Van Hool tc specific requirements for 38-tonne gcw operations. Specification of the tri-axle semi trailer included RO-R axles or monoleaf springs and twin mounted 8.25X15 tyres.

Bodywork

Right: Although Wilson's 12m double-decked semi-trailer would scoop no prizes for style and beauty, in terms of sheer practicality it takes some beating.

The 4.0m (13.1ft) high, 2.5m (8.2(t) wide body has two floors with headroom between both floors of 1.7m (5.6ft) and gives an overall 90cm (118cuyd) capacity. Kerb weight is 6 tonnes, retail price a competitive £16,000.

it is built at Wilson Double-Deck Trailer's Belfast plant, Axles and suspensions are made by RO-R, Anchorlock spring park brakes are standard and Maxaret anti-lock braking systems are also included.

Below: RECENTLY formed LAG UK showed a 50cm (15.4cuyd) tipping bulk tanker built to ADR regulations for carrying hazardous chemicals.

LAG saves around 200kg (441lb) by using a 24 volt motor instead of an auxiliary engine. Electrical and hydraulic overload switches are fitted. Discharge cone and pipe are of stainless steel, the cone being fitted with a removable vibrator to prevent clogging by sticky materials.

Right: RO-R has redesigned its Indair system replacing its earlier conventional full width axle with two separate beam halves to give a fully independent suspension, saving 10 per cent weight. Heavy-duty shock absorbers provide extra axle support when crossing ramps or during ferry loading. Above: ONE Silverspeed-bodied ex hibit had an alloy Luton van body mounted on a Freight Rover Sherpa chassis-cab and another was a boxvan body for Ford and Slater Truckline using Dawn press grp panels on a steel backing frame.

A full-depth alloy shutter is specified for the rear closure on the boxvan, but the steel rear framework will accept a tail-lift.

Below: Charles Roberts Engineering had a typical 12,000-litre (2.640gal) four-compartment multipurpose vehicle on show, mounted on a Ford Cargo 1615 chassis.