Lockheed Brake Development

Page 85

If you've noticed an error in this article please click here to report it so we can fix it.

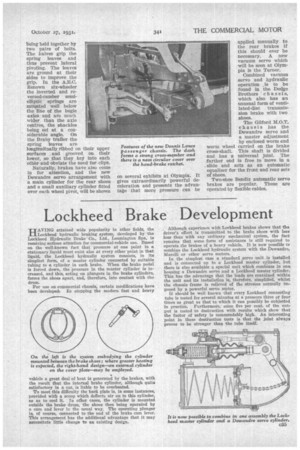

AVING attained wide popularity in other fields, the 1.1Lockheed hydraulic braking system, developed by the Lockheed Hydraulic Brake Co., Ltd., Leamington Spa, is receiving serious attention for commercial-vehicle use. Based on the well-known fact that pressure at one point in a stationary liquid mnst exist also at every other point in that liquid, the Lockheed hydraulic system consists, in its simplest form, of a master cylinder connected by suitable tubing to a cylinder in each brake. When the brake pedal is forced down, the pressure in the master cylinder is increased, and this, acting on plungers in the brake cylinders, forces the shoes apart, and, therefore, into contact with the drum.

For use on commercial chassis, certain modifications have been developed & In stopping the modern fast and heavy vehicle a great deal of heat is generated by the brakes, with the result that the internal brake cylinder, although quite satisfactory in a car, is liable to be overheated.

To meet this difficulty the back plate is, in some instances, provided with a scoop which deflects air on to this cylinder, so as to cool it. In other cases, the cylinder is mounted outside the brake drum, the shoes then being operated by a cam and lever in the usual way. The operating plunger is, of course, connected to the end of the brake cam lever. This arrangement has the additional advantage that it may necessitate little change to an existing design. Although experience with Lockheed brakes shows that the driver's effort is transmitted to the brake shoes with less loss than with any ordinary mechanical system, the fact remains that some form of assistance is still required to operate the brakes of a heavy vehicle. it is now possible to combine the Lockheed hydraulic system with the Dewandre, Mardi or other servo motors.

In the simplest case a standard servo unit is installed and is connected up to a Lockheed master cylinder, but there is also available a special unit which combines in one, housing a Dewandre servo and a Lockheed master cylinder. This has the advantage that the loads are contained within the unit and its installation is, therefore, simplified, whilst the chassis frame is relieved of the stresses normally imposed by a powerful servo motor.

It should be well known that every Lockheed connecting tube is tested for several minutes at a pressure three or four times as great as that to which it can possibly be subjected in practice. Furthermore,some five per cent. of the output is tested to destruction with results which show that the factor of safety is commendably high. An interesting point in these destruction tests is that the joint always proves to be stronger than the tube itself.