Fuel Pump with Unusual Possibilities

Page 73

If you've noticed an error in this article please click here to report it so we can fix it.

J)TIRING the past three years the compression-ignition engine has made rapid progress, very largely duo to the development of the fuel pump, which is, in reality, the key to the whole question. So far as commercial practice is concerned, the single-plunger type of pump is the one which is being universally adopted. It has achieved a considerable measure of success, but it is realized that it has certain drawbacks.

Mechanical considerations limit the possible rate of acceleration of the plunger at high speeds and, in consequence, the fuel-injection curve is not so controllable as might be desired. As regards the duration of injection, this depends upon the cam contour employed. Further, the volume of oil injected per stroke is dependent upon the diameter and stroke of the pump plunger ; in the ease of small engines requiting diminutive fuel droplets, production difficulties occur in the accurate construction of the parts.

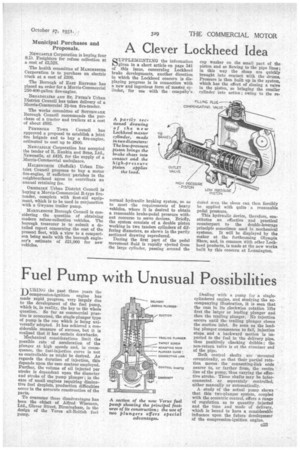

To overcome these disadvantages has been the object of Alfred Wiseman, Ltd., Glover Street, Birmingham, in the design of the Verus all-British fuel pump. Dealing with a pump for a singlecylindered engine, and studying the accompanying illustration, it is seen that the cam in its clockwise rotation lifts first the larger or leading plunger and then the trailing plunger. No injection occurs until the trailing plunger closes the suction inlet. So soon as the leading plunger commences to fall, injection stops and a backward motion is imparted to the fuel in the delivery pipe, thus positively checking dribble ; the non-return valve is at the atomizer end of the pipe.

Both control shafts arc mounted eccentrically; so that their partial rotation moves the connecting-link ends nearer to, or farther from, the centre line of the pump, thus varying the effective stroke. These shafts may be interconnected or separately controlled, either manually or automatically.

A study of the actual pump shows that this two-plunger system, coupled with the eccentric control, offers a range of regulation as to quantity injected and the time and mode of delivery, which is hound to have a considerable influence upon the future development of the compression-ignition engine.