Improvements in the Z-type Berliet Engine.

Page 11

If you've noticed an error in this article please click here to report it so we can fix it.

IN TliU later models of the ".4-type Be-diet engine, which bore of110 tam. and a stroke of 140 Mm. and

is used on the 2 21-ton and.ti-ton chassis, the system of-lubrication has

been slightly modified and several-theminor improvements have been em

bodied. .-.. . .

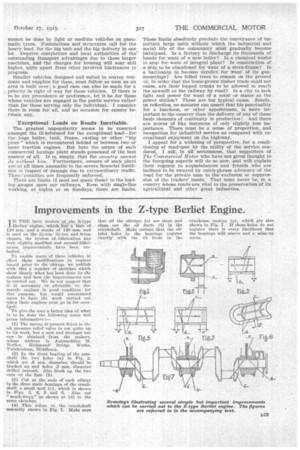

To enable users-9£ these vehicles t6 effect .these modifications in engines issued prior to the -change We pnbliSh with this a number of sketches which show 'clearly what has been done by the makers and how the improvements can be carried out. We do not suggest that it is necessary or advisable to dismantle engines in good condition for this purpose, but would recommend users to have the work carried out when their engines next go in for overhgul.

To give the user a better idea of what is to be done the following notes -will prove informative : (.1) The spring at present fitted in the oil pressure relief valve is not quite up to its work. but a new and stronger one can he obtained from the makers, whose address is Automobiles M. lierliet, Richmondliridge Works, Twickenham, Middlesex.

(2) In the front bearing of the camshaft the two holes (a) in Fig. 2, which are .6 mm. diameter, should be blocked up and holes .3 tom. diameter drilled instead. Also block up the two cuts on the face (b).

(2) Cut at the ends of each oilway In the three main bearings of the crankshaft a small well (c), which is shown in ,Figs. 3, 4, 5 and 6. Also Cut "muck-ways," as shown at (d). in the same sketches.

-(4) This refers . to the crankshaft assembly shown in Fig. 7. Make sure ihat all the oilways (e) are clear and elean out the oil duets (f) in the crank-shaft. Make certain that the oilinlet holes in the bearings register exactlywith the oil feeds in the crankcase casting (g), which are also shown in Fig. 7. If these holes do not register there is every likelihood -that the bearings will starve and a seize-up occur.