There are giants in the employ of Derek Crouch

Page 35

Page 36

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

Opencast mining is the name of the game and this company has been excavating for over forty years. Massive dump trucks are an essential part of the operation as David Wilcox finds out

ON THE DAY that saw most of the haulage industry celebrating the increase of permitted gross vehicle weights from 32 tons to 38 tonnes I was looking at vehicles that weighed in at well over 100 tonnes — and all on two axles.

Before Nick Lester and his friends at Transport 2000 choke on their real ale, I hasten to add that these super-heavyweights are not on the public roads; they are strictly site-only vehicles.

They belong to Derek Crouch (Contractors), the opencast mining and civil engineering arm of the Peterborough-based Derek Crouch Group of companies which also has construction and related equipment sales interests.

The company won its first opencast mining contract in 1945 and is now one of the top half-dozen companies in this field.

There are relatively few sizeable opencast coal mines in the United Kingdom; Derek Crouch operates five. When the NCB Opencast Executive puts the operation of a site up for tender it normally selects about eight companies to tender.

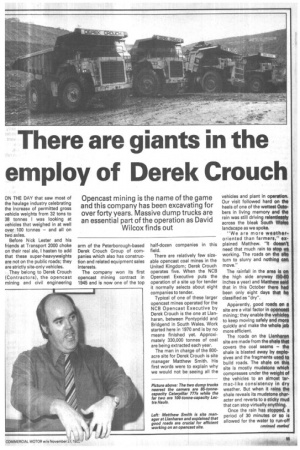

Typical of one of these larger opencast mines operated for the NCB Opencast Executive by Derek Crouch is the one at Llanharan, between Pontypridd and Bridgend in South Wales. Work started here in 1970 and is by no means finished yet. Approximately 330,000 tonnes of coal are being extracted each year.

The man in charge of the 800acre site for Derek Crouch is site manager Matthew Smith. His first words were to explain why we would not be seeing all the

vehicles and plant in operation. Our visit followed hard on the heels of one of the wettest Ooto. hers in living memory and the rain was still driving relentlessly across the bleak South Wales landscape as we spoke.

"We are more weatheroriented than farmers," explained Matthew. "It doesn't need that much rain to stop tee working. The roads on the site turn to slurry and nothing can move.".

The rainfall in the area is on the high side anyway (50-60 inches a year) and Matthew said that in this October there had been only eight days that he classified as "dry".

Apparently, good roads on a site are a vital factor in openoat • mining; they enable the vehicles to keep moving safely and more quickly and make the whole job more efficient.

The roads on the Llanharan site are made from the shale that covers the coal seams — the shale is blasted away by explosives and the fragments used to build roads. The shale on this site is mostly mudstone which compresses under the weight of the vehicles to an almost tarmac-like consistency in dry weather. But when it rains the shale reveals its mudstone character and reverts to a sticky mud that can stop virtually anything.

Once the rain has stopped, a period of 30 minutes or so is allowed for the water to run-off and then grading machines with an elongated wheelbase and a mid-mounted blade have to run along the roads to level them and get down to a harder surface for the dump trucks to operate.

Permanent, properly constructed roads are out of the question. First, they would be too costly to build because of the extremely high axle weights they would have to bear. And secondly, the roads on an opencast site are a movable feast; they have to move as the coal face is eaten away. The actual hole or "void" on an opencast mine is constantly travelling forwards as the coal face advances and the "overburden" (the clay and shale removed from above the coal seams) is tipped at the back of the void to infill it.

Topsoil and subsoil are stored in mounds to be used as baffle banks to minimise noise from the operation while the site is working and then used to cover the whole area when it is fully restored.

The conditions at Llanharan when CM visited the site were such that the large muck-shifting dump trucks could not operate but the smaller coal-carrying lorries could and were valiantly battling to and fro.

• The Llanharan site is immense, both in area and depth. The roads wind down to the bottom of the coal face so that their gradient does not generally exceed one in ten. The Llanharan ; coal is removed in a series of nine cuts, each taking 18 months to two years to complete.

For each cut the top soil and sub-soil has to be removed first before the shale is blasted to reveal the coal face. This has to be cleaned by machine and then manually with shovels to make sure the coal mined is pure and does not include shale and other material. An NCB Opencast Executive inspector will make sure this is satisfactorily completed.

Opencast mining is a highly capital intensive industry which largely explains why there are so few companies able to handle jobs like Llanharan. On this site alone, Derek Crouch has vehicles and plant worth over £10 million at current prices.

The most expensive pieces of equipment are two Ruston Bucyrus 195 face shovels with 9.2cum 412cuyd) shovels, used for the muck-shifting, that is, loading the overburden into the big dump trucks. They cost around -£1 million each.

A comparative bargain at a mere £3/4 million or so each are two Ruston Bucyrus 150 face shovels with 5.4cum (7cuyd)

capacity buckets.

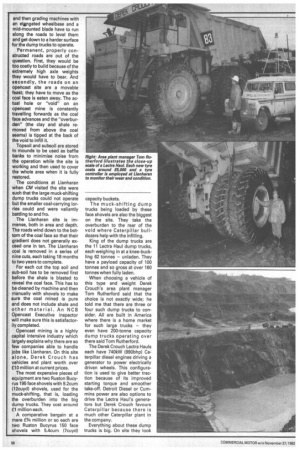

The muck-shifting dump trucks being loaded by these face shovels are also the biggest on the site. They take the overburden to the rear of the void where Caterpillar bulldozers help with the infilling.

King of the dump trucks are. the 11 Lectra Haul dump trucks, each weighing in at a knee-buckling 62 tonnes — unladen. They have a payload capacity of 100 tonnes and so gross at over 160 tonnes when fully laden.

When choosing a vehicle of this type and weight Derek Crouch's area plant manager Tom Rutherford said that the choice is not exactly wide; he told me that there are three or four such dump trucks to consider. All are built in America where there is a home market for such large trucks — they even have 200-tonne capacity dump trucks operating over there said Tom Rutherford.

The Derek Crouch Lectra Hauls each have 740kW (990bhp) Caterpillar diesel engines driving a generator to power electrically driven wheels. This configuration is used to give better traction because of its improved starting torque and smoother take-off. Detroit Diesel or Cummins power are also options to drive the Lectra Haul's generators but Derek Crouch favours Caterpillar because there is much other Caterpillar plant in the company.

Everything about these dump trucks is big. On site they look arge but because everything out here is on a similar scale you do lot get a true impression of their lize. Once inside the maintenince building you see them in heir true light, towering above Iverything else. They cost a cool 300,000 each.

Just marginally cheaper and mailer are the 10 Caterpillar 777 lump trucks at Llanharan. They lave a payload capacity of 85 onnes and are driven convenionally by 634kW (850bhp) Caerpillar diesel engines. Price: [bout £250,000 each.

Tyres are correspondingly ex ■ ensive. the 27.00x49 covers for he Lectra Haul are approxinately £5,000 each. With 21 imilarly sized dump trucks to ook after there is a tyre controler at Lianharan whose sole res)onsibility is to maintain and nonitor the tyres. Because of he high annual rainfall tyre year here is quicker than on ,ome other opencast sites beause of slippage.

Life and use of the dump rucks is measured in hours, not niles, and each vehicle has a imeclock that records cumulaive hours of operation. At Llanlaran an average year's operaon for a dump truck totals ,500 hours; on other opencast ites operated by Derek Crouch ip North where there is less ainfall this figure is nearer 5,000 tours.

Tom Rutherford is planning to get at least 50,000-60,000 hours' life out of the dump trucks — he knows of a Lectra Haul in America that has passed the 90,000 hour mark. He explained that the Lectra Haul is a wellproven design, first introduced in the early sixties, and that one never really wears out; all the component parts can be replaced one by one until you end up with what amounts to a new dump truck.

Derek Crouch services the dump trucks every 250 hours in workshops on the site. Although as site-only vehicles they do not have to pass an MoT test, Tom Rutherford said that their maintenance has to be just as good, if not better. The more expensive the vehicle, the more punitive is downtime and the greater the cost of repairs.

When an opencast mine is finally worked out and restored, the vehicles and plant have to be moved on to another site. In the case of the big dump trucks this means taking them by road under Special Types dispensation to the nearest port and shipping them by sea to the, port nearest their destination.

The drivers of the dump trucks do not need hgv driving licences because they are not on public roads. Most of the Derek Crouch drivers start as tip-men, supervising the tipping and after six months or so may apply for other jobs such as dump truck driving. In addition to its own driver training programme the company has its own system of internal licences which entitle employees to drive a particular class of vehicle. The dump truck driving training has a safety content that follows the guidance suggested by the Federation of Civil Engineering Contractors, the relevant trade association.

Site manager Matthew Smith said that he had never seen an example of bad driving on his site — the responsibility of driving such large and expensive vehicles is discipline enough. There is a 15mph limit on the Lectra Hauls running downhill to obtain maximum electrical retardation.

There is also a rule on the site that says nobody can overtake a dump truck unless the dump truck driver agrees by moving over and giving the appropriate signal. The overtaking vehicle must pass on the inside (left) because the left-hand drive Lectra Hauls have better visibility on that side.

While the muck-shifting operation goes on to clear the next area of working the hydraulic excavators and loaders are eating away at the coal face. They load the coal into a fleet of 10 Foden six-wheeled coalcarrying lorries, fitted with Neville Charrold alloy tipping bodies which carry a payload of 17.5 tonnes. These half-cab tippers with Cummins NH220 engines are six or seven years old now but still give sterling service on site, especially when one considers that they are really only semi-off road vehicles.

The Fodens take the coal up out of the bottom of the site to the coal stocking grounds or direct for washing and screening at the top of the site. It finally leaves Llanharan bound for the customers by railway wagon.

Coal extraction at Llanharan opencast mine will continue for another four years. After that Derek Crouch (Contractors) will spend a further five years restoring the site.