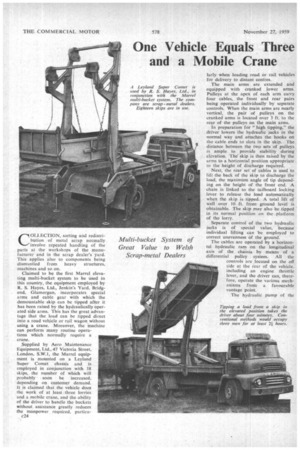

One Vehicle Equals Three and a Mobile Crane

Page 64

Page 65

If you've noticed an error in this article please click here to report it so we can fix it.

COLLECTION, sorting and redistribution of metal scrap normally involve repeated handling of the parts at the workshops of the manufacturer and in the scrap dealer's yard. This applies also to components being dismantled from heavy structures, machines and so on.

Claimed to be the first Marrel elevating multi-bucket system to be used in this country, the equipment employed by R. S. Hayes, Ltd., Jenk in's Yard, Bridgend, Glamorgan, incorporates special arms and cable gear with which the demountable skip can be tipped after it has been raised by the hydraulically operated side arms. This has the great advantage that the load can be tipped direct into a road vehicle or rail wagon without using a crane. Moreover, the machine can perform many routine operations which normally require a crane.

Supplied by Aero Maintenance Equipment, Ltd., 47 Victoria Street, London, S.W.1, the Marrel equipment is mounted on a Leyland Super Comet chassis and is employed in conjunction with 18 skips, the number of which will probably soon be increased, depending on customer demand. It is claimed that the vehicle does the work of at least three lorries and a mobile crane, and the ability of the driver to handle the buckets without assistance greatly reduces the manpower required, particu c24 larly when loading road or rail vehicles for delivery to distant centres.

The main arms are extended and equipped with cranked lower arms. Pulleys at the apex of each arm carry four cables, the front and rear pairs being operated individually by separate controls. When the main arms are nearly vertical, the pair of pulleys on the cranked arms is located over 3 ft. to the rear of the pulleys on the main arms.

In preparation for " high tipping," the driver lowers the hydraulic jacks in the normal way and attaches the hooks on the cable ends to slots in the skip. The distance between the two sets of pulleys is ample to provide stability during elevation. The skip is then raised by the arms to a horizontal position appropriate to the height of discharge required.

Next, the rear set of cables is used to lift the back of the skip to discharge the load, the maximum angle of tip depending on the height of the front end. A chain is linked to the tailboard locking lever to release the load automatically when the skip is tipped. A total lift of• well over 10 ft. from ground level is obtainable. The skip may also be tipped in its normal position on the platform of the lorry.

Separate control of the two hydraulic jacks is of special value, because individual lifting can be employed to correct unevenness of the ground.

The cables are operated by a horizontal hydraulic ram on the longitudinal axis of the chassis by means of a differential pulley system. All the controls are located on the off side at the rear of the vehicle. including an engine throttle lever, and the driver can, therefore, operate the various mechanisms from a favourable vantage point.

The hydraulic pump of the syste is mounted on a bracket underslung from the chassis on the off side

and driven from the gearbox power takeif through a flexibly jointed propeller shaft. A large reservoir tank is centr Ily mounted on the chassis. Combined weight of skip and lifting gear is• 1 to 4 cwt. and the normal load of a skip s 7 tons. It can, however, handle up h 9 tons.

A kip can be loaded from ground level ir unloaded by one man in three minu es, and the total time for tipping from the elevated position into a road or ra 1 vehicle is less than four minutes. Load rig in the scrap yard or on a disng site requires far less manual than is necessary for a convenlorry because of the skip's low mant effort tiona heigh e case of a workshop producing a r output of scrap, a skip is left on emises and is progressively filled by transfer from the various depart

a typical instance it is collected last-minute advice given over -the one.

en a lorry is used for scrap collec

tion the parts are generally piled in an unsightly heap and loading may occupy two or more men over an hour. lls space-saving advantage may also be of importance to the manufacturer, and it can be of great benefit with regard to

cleanliness. •

After filling with scrap in the dismantling yard a skip is normally transported a distance of less than 100 yd. and unloaded into a rail wagon. When a normal lorry was used for this work, unloading was performed by tHree men and total transfer time sometimes amounted to n hours.

Work Over 50-mile Radius

In addition to routine work in the scrap. yard, the vehicle collects and delivers skips over a radius Of some 50 miles. A load may comprise heavy girder sections of a bridge or building structure which is being dismantled.

When the vehicle returns to the dumping yard, the girders have to be removed by a mobile crane. In a rush period the three mobile cranes in the yard are fully employed, and if the girders have to be unloaded from a conventional lorry the vehicle may be delayed a bang -time before a crane is available. When transported in the Leyland Marrel vehicle, the skip can be .unloaded immediately to release the lorry, and driver for other work.

Because component grading according to type of material is a major problem, the multi-bucket system can provide extra advantages without a large capital expenditure on additional equipment. This applies to work at the breaker's yard, where a number of skips can be loaded with different types of scrap at the same time, and in some cases extends also to sorting parts on workshop premises.

The manufacturer can be supplied with a number of-skips if different grades of material are involved and ..the skips can be selectively loaded without extra labour. This also facilitates costingand price-fixing.

A tribute to the system is provided by a special leaflet prepared by the Hayes company for distribution to their customers, which shows the advantages of skip transport in -terms of works organization.