How Tyre Mileage is Wasted

Page 31

Page 32

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

The Influence Exerted by Different Classes of Surf ace and Contour and What Can Be Done to Alleviate Wear on Tyres byModifying Driving Tactics

No. 8— Road Surfaces FOR some time prior to the outbreak of -war the trend in road-making was towards the rougher types of surface. This was all to the good, in the interests of' safety. Previously, with an aim to securing travel comfort, roads were constructed to a glassy smoothness. which offered 'practically no grip and which was unsafe in wet weather.

The 'f smoothness." myth has been exploded. We know now that we can have just as comfortable a ride on a rough-laid surface, provided that it is free from major irregularities. Grip and safety are much improved without increasing vehicle vibration.

Those pre-war roads .were laid with those two ends in view—comfort and safety. Tyre ' wear was not considered, because there was no rubber problem. Nowadays tyre wear is a third vital factor which must be borne in mind in relation to road surfaces. To-day, in Britain, there are thousands of miles of "roughed concrete roads—ideal from the points of view of comfort and , safety, but

taking heavy toll of rubber: It -is unlikely that surfaces wl be changed to suit the times. The only way to reduce tyre wear to a

-minimum is to study the effects of the different -road-building materials, and to regulate one's.driving accordingly.

In the previous article, " Speed and Braking," it was seen how the tyre tread was the medium through which the forces of propulsion and braking were transmitted t8 the road surface. It Was seen, too, how the tyre's capacity for grip was constantly torn between these two opposing forces. This gave someidea of the stresses that a tyre has to withstand under normal conditions. Obviously, the degree of abrasion offered by the road surface is a further factor affecting tread life.

For and Against Wood-sett Surfaces

One of the best surfaces from the tyre's point of view is composed of wood setts. It offers only moderate friction and, consequently, poor grip. In view of the desperate shortage of rubber it seems that tyre mileage is almost more important than safety, so I suppose that we must consider a wood-sett road as ideal in the light of present-day requirements. In peace-time we can regard it only with the antipathy it deserves. It is the

foremost cause of accidents due to skidding.

Taking wood setts' as the standard " ideal " road surface, let us see the relative effects which the other types have on tyre life.

Cobble stones vary rather. When old and rounded they are almost as easy on the tyre as are wood setts, but when new and rough they are nearly as harsh as concrete.

Tarmacadam is a little harder than wood. Tyres run continuously on it will give approximately 10 per cent, less mileage than on our "standard surface.

Concrete shows a big drop (28 per cent.) when compared with wood surfaces. Modern -concrete is laid with a studied roughness (Fig. 2), which certainly gives good gripping qualities but increases the rate of tyre wear. Thus, all other things being equal, 72 miles run on a concrete road will wear away as much rubber as 100 miles on wood setts.

Loose, flinty country roads are even worse. They involve a loss of 36 'per cent. of normal mileage. . Every 64 miles travelled on such a surface uses as much rubber as 100 miles on wood setts

Last time I mentioned the relative effects of different road surfaces, in the issue of "The Commercial Motor" dated January 6, 1939, I was put " On the mat" by a correspondent who said that my statements were " too sweeping," He pointed out that the effect of the different surfacestarmacadam and concrete particularly—varies with the quality and size of the stone ,aggregate used for the surfacing material. This, of course, is obvious. The figures 1 have given are for average surfaces of the types mentioned.

Some time ago I said that it was up to the operator to eliminate every adverse influence affecting tyre life which is under his control. Road surfaces, it may be argued, are quite beyond the operator's control, so that nothing can be done about it.

This is not strictly true. I am not suggesting that drivers should avoid rough roads altogether. That is out of the question. But I do suggest that when rough roads are encountered a slight modification in driving tactics will do much to alleviate the wear on the tyres.

Irrespective of road surface, the friction between. the tread and the ground is reduced to a minimum when the tyre is rolling easily, that is, when there is no undue propulsion stress due to high speeds, and when braking is gradual and is used as little as possible.

In my contribution on "Speed and Braking" it was noted that an increase.in speed from 30 m.p.h. to 40 m.p.h. resulted in an increase of 24 per cent, in the rate of tyre wear, and we have seen in the present article that a change from wood setts to concrete results in an incre.ase of 28 per cent. in the rate of wear. Thus it is a reasonable conclusion that 40 m.p.h. on a concrete road will give a rate of wear roughly, 50 per cent. greater than normal;

Conversely, it is fair to assume that if the speed be reduced from 30 mph. (our standard " speed: for the purpose 8/ comparison) to 20 m.p.h. when travelling along a concrete road, -the increase in rate of wear, due to the rougher concrete surface, would be offset by the decrease in speed.

A Factor Under the Driver's Control The factor of speed is definitely under the driver's control, and he can nie it as a means for overcoming the unctntrollable factor of roadsurface variations.

Even on wood setts there is an increase in the rate of wear if the surface be bumpy and irregular. This applies to the other surfaces as well. Shocks due to road irregulari ties cause excessive vibeation. The tyre is so bounced about that it momentarily leaves the road every few seconds. This leads to wheelspin, which causes increases in friction between the tread and the road. Here again, if the speed of the vehicle be reduced to conform with the conditions, the excessive vibra: tion due 'to road shocks will be reduced.

This may sound like straining the point a little, but if you have any doubt about the value of reductions in speed when obstructions are encountered you should compare the shock to the vehicle when hitting a

deep pot-hole at 5 m.p.h. with that when hitting it at 40 m.p.h. The one is just a gentle bump and the other makes you wonder .whether the

vehicle is going to fall to pieces.

Do not forget, too, that the shock "which the tyre receives is even greater than that which the driver receives. By the time it reaches the driver it is partly absorbed by the tyre, the road springs and the cushion upholstery. Personally, I consider that 20 m.p.h. is the maximum economical speed o n bumpy country roads. Same of them call for very much less.

Closely related to the question of road surfaces is the effect of hilly and twisty roads: Hills and .sharp bends seem to go together. Both have a bad effect on tyres. The surmounting of steep gradients obviously requires a greater tractive effort on the part of the tyres with a corresponding increase in the rate of wear. Likewise, on the descent, a greater use of the brake is necessary, with similar results.

In addition, there is the question of load transference to be considered. Alterations in gradient cause temporary redistribution of the load. The front tyres may be momentarily overloaded and the rear tyres relieved, or vice versa. But more about this later.

The effect of bends in the road is much the same. The tendency is for the load to pitch to the outside of the curve, thus overloading the tyres on that side and wrenching the tread in a crosswise direction. It is only momentary, of course, and may seem to be of little consequence, but when it happens every few hundred yards, as it does in hilly country, the effect on tread wear is considerable.

A slightly hilly road with a fair sprinkling of bends will increase the rate of wear by 25 per cent., whilst really steep gradients with many sharp turns will account for 50 per cent, more wear. Here, again, the antidote is a reduction of speed and minimum use of the brakes.

On bends, a reduced speed minimizes the roll of the vehicle, and the crosswise stress on the tread is alleviated. On steep descents the use of a low gear, instead of the brake, also reduces the stress on the tyre.

Movements Between Tread and Road In my article on "Concussion Injuries" (No. 6 of this series) I said that a tyre was "intended to roll through life, not smash its way through." This is not strictly correct, but it served at the time' to bring home 'my point. A tyre does not 'just roll," as does an inflexible steel wheel. There are many sorts of movements going on which are seldom realized:—mostly between the tread and the road surface.

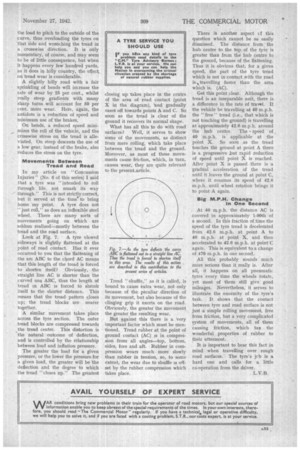

Look at Fig. 7. A tyre viewed sideways is slightly flattened at the point of road contact. Has it ever occurred to you that the flattening of the arc ABC to the cllord AC means that this length of the tread is forced to shorten itself? Obviously, the straight line AC is shorter than the curved one ABC, thus the length of tread in ABC is forced to shrink itself to the shorter distance. This means that the tread pattern closes up; the tread blocks are nearer togeher.

A similar movement takes place across the tyre section. The outer tread blocks are compressed towards the tread centre. This distortion is the natural outcome of deflection, and is controlled by the relationship between load and inflation pressure.

The greater the load for a given pressure, or the lower the pressure for a given load, the greater will be the deflection and the degree to which the tread "closes up." The greatest

closing up takes place in the centre of the area of road contact (point X in the diagram), 'and gradually eases off towards points A and C. So soon as the tread is clear of the ground it recovers its normal shape.

What has all this to do with road surfaces? Well, it serves to show some of the movements, as distinct from mere rolling, which take place between the tread and the ground. Moreover, as most of these movements cause friction, which, in turn, causes wear, they are quite relevant to the presentarticle.

Tread " shuffle," as it is called, is bound to cause extra wear, not only because of the peculiar direction of its movement, but also because of the clinging grip it exerts on the road. Obviously, the greater the movement the greater the resulting wear.

But against this there is a Very important factor which must be mentioned. Tread rubber at the point of ground contact (AC) is in compression from all angles—top, bottom, • sides, fore and aft. Rubber in compression wears much more slowly than rubber in tension, so, to some extent, the wear due to shuffle is offset by the rubber compression which takes place. There is another aspect cf this question which cannot be so easily dismissed. The distance from the hub centre to the top of the tyre is greater than from the hub centre to the ground, because of the flattening. Thus it is obvious that, for a given speed, the part of the tyre tread which is not in contact with the road is „travelling faster than the area which is. (AC).

Get this point clear. Although the tread is an inseparable unit, there is a difference in the rate of travel. If the vehicle be travelling at 40 m.p.h. the "free" tread (i.e., that which is not touching the ground) is travelling at approximately 42.6 m.p.h. around the hub centre. The speed of, 40 m.p.h. is applicable at the point X. So soon as the tread touches the ground at point A there is a progressive but rapid reduction of speed until point X is reached. After point X is passed there is a gradual acceleration of the tread until it leaves the ground at point C, where it resumes its speed of 42.6 m.p.h. until wheel rotation brings it to point A again.

Big M.P.H. Change In One Second

At 40 m.p.h. the distance AC is covered in approximately 1-90th of a second. In this fraction of time the speed of the tyre tread is decelerated from 42.6 m.p.h. at point A to 40 m.p.h.' at point X, and then accelerated to 42.6 m.p.h. at point C again. This is equivalent to a change of 470 m.p.h. in one second.

All this probably sounds much more serious than it really is. After all, it happens on all pneumatic tyres every time the wheels rotate, yet most of them still give good mileages. Nevertheless, it serves to illustrate the enormity of the tyre's task. It shows that the contact between tyre and road surface is not just a simple rolling movement, free from friction, but a very complicated system of movements, all of them causing friction, which tax the wonderful properties of rubber to their uttermost.

It is important to bear this fact in mind when travelling over rough road surfaces. The tyre's jcb is a hard one and calls for a little co-operation from the driver.