MAKING BEST• USE OF THE FORD.

Page 70

If you've noticed an error in this article please click here to report it so we can fix it.

Valuable Advice on Every Phase of Ford Transport, which will Appeal to the• Owner, Driver, and Repairer.

IN TT-11b series of hints concerning the Ford light chassis arid ton truck wherever they or e employed for commercial purposes, we endeavour to deal with the subject from every view-point, so that the advice given will. appeal to the owner, driver, maintenance engineer, or mechanic. Valuable sources of information are -6eing tapped for this purpose, and it should be understood that the advice given will be derived from those with an intimate knowledge of the subject. We shall -welcome for inclusion among the hints those which have:proved of value to individual users and will make suitable remuneration for any published. What we desire are the results of pra,ctices

136.—Rethreading a Spring Perch in Situ.

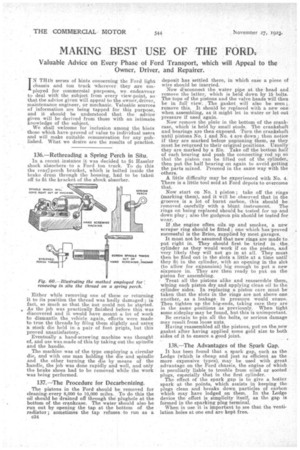

In a recent instance it was decided to fit Hassler shock absorbers to a. Ford ton truck. To do this tha reaelperch bracket, which is bolted inside the brake drum through the housing, Mal to be taken off to fit the bracket of the shock absorber.

Either while removing one of them or returning it to its position the thread was badly damaged ; in fact, so much so that the nut could not be stArted. As the job was practically finished before this was discovered and it wvuld -have meant a lot of work to dismantle the vehicle again, efforts were made to true the threads by filing them slightly and using

stock die held in a pair of foot prints, but this proved unsatisfactory. Eventually a hand-screwing machine was thought of, and use was made of this by taking out the spindle and the handle.

The machine was of the type employing a circular die, and with one man holding the die and spindle and the other turning the die by means of the handle, the job was done rapidly and well, and only the brake shoes had to be removed while the work was being performed.

137.—The Procedure for Decarbonizing.

The pistons in the Ford should be removed for deaning,every 8,000 to 10,000 miles. To do this the oil should be drained off through the plughole at the bottom of the crankcase. The water should also be run out by opening the tap at the bottom of the radiator ; sometimes the tap refuses to run as a

034 deposit has settled there, in which case a piece of wire should be inserted.

Now d4scortnect the water pipe at the •head and remove the latter, which is held down by 15 bolts. The tops of the pistons and the valve heads will then be in full view. The gasket will also be seen ; remove this. It should be replaced with a new one when assembling, as it might let in water or let out pressure if used again.

Now remove the plate in the bottom of the crankcase, which is held by small studs. The crankshaft and bearings are then exposed. Turn the crankshaft until pistons No. 1 and No. 4 are down ; then notice if they are marked befoae unpinning them, as they must be returned to their original positions. Usually they are marked by a file. Take off the bottom half of each bearing and push • the connecting rod up so that the piston can be lifted out of the cylinder, then put the half bearing on again to avoid getting the parts mixed. Proceed in the same way with the others.

A little difficulty may be experienced with No. 4. There is a little tool sold at Ford depots to overcome that.

Now start on No. 1 piston ; take off the rings (marking them), and it will be observed that in the grooves is a lot of burnt carbon, this should be removed, carefully with a blunt. instrument. The rings on being replaced should be tested for up and down play ; also the gudgeon pin should be tested for wear.

If' ,,the engine often oils up and smokes, a new scraper ring should be fitted ; one which has 'proved successful is the.Brico, supplied by most garages.

It must not be assumed that new rings are made to put right in. They should first be tried in the‘ cylinder as they would 'work if on the piston, and very likely they will not go in at all. They musk then be filed out in the slots a little at a time until they ft in the cylinder, with an opening in the slot (to allow for expansion) big enough to put a new sixpence in. They are then ready to put on the piston for assembling.

Treat all the pistons alike and reassemble them, wiping each piston dry and applying clean oil to the cylinder sides. In replacing a piston care must be taken that the slots in the rings are not above one another, as a leakage in pressure would ensue. Then tighten up the big-ends, taking care they are in the same positions as previously. • When tight some sideplay may he found, but this is unimportant.

Be certain to pin all the bolts, or serious damage may result from loose nuts.

Having reassembled all the pistons, put on the.new gasket after having applied some gold size to bath aides of it to ensure a good joint.

138,—The Advantages of the Spark Gap.

It has been found that a spark gap, such as the Lodge (which is cheap and just as efficient as the more expensive types), may be used with great advantage on the Ford chassis, the engine of which is peculiarly liable to trouble from oiled or sooted plugs, especially that in the first cylinder.

The effect of the spark gap is to give a hotter spark at the points, which assists in keeping the plugs clean and breaks down particles of carbon which may have lodged on them. In the Lodge device the effect is simplicity itself, as the gap is formed in the sparking plug terminal. When in use it is important to see that the ventilation holes at one end are kept free.