• T . HERE is probably no name so generally associated with steel tubes as that of Accles and

Page 46

Page 47

Page 48

If you've noticed an error in this article please click here to report it so we can fix it.

, Pollock, Ltd., but it is not so widely . known that this company also makes a large proportion of the rolled-metal sections used in passenger-vehicle bodybuilding in the automobile industry and for ' many other purposes.

Cold-drawn steel tubes of any size, from 0.0M-in.

bore to about 5 ins, in diameter, are manufactured, wnilst, from strip material ranging in width from in. to 141 ins., and in thickness from 0.005 in. to in., metal sections of any practicable shape are developed and can be supplied up to 110 ft. in length. Among these are the well-known Metropolitan-Cammell, Park Royal, Brush and other pillar and strut sections, the Rawlings window framing, and countless others of patented designs and otherwise. The standard material used is bright mild steel, but stainless steel, non-ferrous metals and alloys can also be employed.

The company's activities do not end with the mere snaking of metal sections, for their manipulation and incorporation in small components, and the preparation of sets of complete units for making up into body-frame units to the designs of coachbuilders are an extensive and important branch.

Rolling Metal Sections.

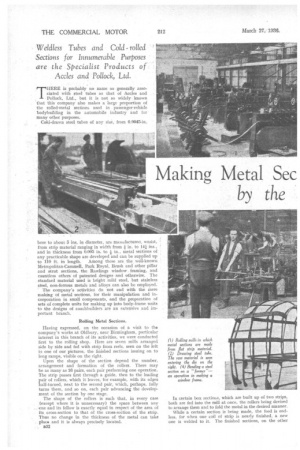

Having expressed, on the occasion of a visit to the company's works at Oldbury, near Birmingham, particular interest in this branch of its activities, we were conducted first to the rolling shop. Here are seven mills arranged side by side and fed with strip from reels, seen on the left in one of our pictures, the finished sections issuing on to long ramps, visible on the right.

Upon the shape of the section depend the number, arrangement and formation of the rollers. There may be as many as 16 pairs, each pair performing one operation. The strip passes first through a guide, then to the leading pair of rollers, which it leaves, for example, with its edges half-turned, next to the second pair, which, perhaps, fully turns them, and so on, each pair advancing the development of the section by one stage.

The shape of the rollers is such that, in every case :(except where it is unnecessary) the space between any one and its fellow is exactly equal in respect of the area of its. cross-section to that of the cross-section of the strip. Thus no change in the thickness of the metal can take place and it is always precisely located.

u32 In certain box sections, which are built up of two strips, both are fed into the mill at once, the rollers being devised to arrange them and to fold the metal in the desired manner.

While a certain section is being made, the feed is endless, for when one coil of strip is nearly finished, a new one is welded to it. The finished sections, on the other

hand, are cut of to the speCified length by a high-speed circular saw mounted on the discharge end of the mill. This•seyers them in mid-air, its speed of rotation obviating the need for supporting the strip close to the cut.

The next machine we inspected is an ingenious tool for shearing sections into lengths, which operation is accorn

plished without damaging the material and with great accuracy, the edges being cut clean and true.

The bending of intricate sections might be thought to present a difficult problem, but it has been solved successfully with similar ingenuity. The work is held against a "former," and a slipper is pulled through and over it, being compelled to follow the contour of the " former " by a powerful spring. Much depends upon the shape and clearances of the slipper and the position of the hinge relative to the point of application of the pressure Window frames were being butt-welded as we passed thfough the shops. These were of one piece with, accordingly, one joint. Sometimes a weld is necessary at each corner. For instance, when the sides, top and bottom are of different section, or when a pressing supplied by the customer has to be incorporated. For these jobs there is a machine in which the four joints are made simultaneously. The principle, however, is the same in both types of apparatus, the frames being welded electrically by the " flash " process.

The frame is gripped close to the break in two pairs of jaws, to which current is supplied at about two volts. So soon as this is switched on, the jaws slowly approach one another. Just before the gap closes, the current arcs across, about 2,000 amps. flowing. This fuses the ends, which are immediately pressed together, the operation ceasing automatically at the crucial moment, that is, when the weld has been properly made and when the dimension effected is correct. The burr or " flash," as it is called in the works, is then ground off and, after subsequent buffing, the joint is indetectable. Now the holes are marked of and punched, and the frames pass on for degreasing.

Automatic Spot Welding.

For spot welding, the resistance system is employed. In this, the electrodes press together the two parts (which are of sheet metal, overlapping, or lying face to face), and when the current is switched on, heat is generated at the point of contact. Time and heat factors are important in this operation and are governed by the thickness of the metal and the area of the weld. A welding machine we inspected is provided with a device which sets the action of the automatic control so that. once adjusted for a specific job, no further skill is demanded from the operative. Among other automobile parts we observed in course of construction at this period were body-frame sections, door frames, roof gutters, twin tubular rolled sections for preventing roof drumming (for L.P.T.B. buses), and certain special units built up from rollings and stampings with welded and flitch-plated joints.

Following the progress of the window frame, the next operation is the application of an oil-base primer, which keys on to the clean 'bare steel, acts as a rust-proofing and serves to receive, later, the selected finish.

Then comes a most interesting operation. Everyone is familiar with window frames, facia-boards, etc., which in appearance resemble oak, mahogany, satinwood, and so forth, but few know how the imitation is accomplished. By Accles and Pollock, Ltd., the Oxvar patented graining process is employed. A copper plate is surface treated from a photograph of an actual piece of wood. To this pigment of appropriate hue is applied and picked up on a soft roller, which, of course, bears the imprint of the grain. From the roller it is skilfully transferred to the article to he finished, the operative manipulating the roller in such a way that the Paint is taken from it in a spiral band.

A •big proportion of the company's output of finished tubular parts comprises furniture and, of this, bus seats

figure largely. They are mainly made entirely of steel, but one exception to the rule which we observed was a set of hid upliniurn grab rails—also for L.P.T.B. buses.

Two . main types of seat frame are produced—those which are welded up, and detachable frames in which the ends are secured to the cross-tubes with screws. It is notable that practically all the furniture welding is done by oxy-acetylene, girl labour being largely employed. An A. and P. • special lightweight seat frame we examined was made of oval-section chrome-molybdenum steel, reinforced at the bends; it weighed only 9 lb. • Passing out of the furniture department, we were shown the rust-proofing shop, where all parts likely to be exposed in service to a rusting influence are treated by Carlatosing, and afterwards receive a coat of special paint.

On our way through the tube section of the works our attention was drawn to many interesting operations in the manufacture of special parts. These are too numerous to record, but among them were bicycle parts, aeroplane struts; extensible ladder units, built for fire escapes and made up to 100 ft. high, feather-light busroof ladders, steering wheels and the well-known Apollo box spanners.

We paused to look in at the testing shop, where the usual apparatus for tensile and hardness testing is included in the equipment. One device of special interest which caught our eye is for checking bore accuracy. A set of short tubes for the Vauxhall concern was being inspected at the time. We. were informed that not more than 0.001 in. 1334

variation in bore longitudinally and radially was permitted. A plug gauge, on the periphery of which is a number of orifices, is a running fit in the tube and to this is fed, through a sensitive fluid-type pressure indicator, gas from an oxygen cylinder. As the tube is passed over the plug any variation in the rate of escape of the gas, caused by irregularities of the bore, is instantly and unmistakably shown.

Tapered tube is in bigger demand than one might imagine, for, apart from automobile requirements. it is used in large quantities for golf-club shafts, fishing rods, vacuum-cleaner parts, stays, etc., the degree of taper required being imparted by an ingenious machine, the functioning of which we are asked not to disclose.

The actual tube drawing is carried out in a vast shop containing mills of various capacities. There is a variety of methods, but the principle is much the same in all.

Forged from the solid by an associated company, hollow cylinders of many lengths, diameters and thicknesses con, . stitute the raw material upon which Accles and Pollock, Ltd., commences proceedings. First, these are annealed; next, they are crushed up at one end for gripping purposes; the tube in the rough is then slipped over its mandrel, or inner die, which is secured on the end of a long bar ; the crushed end is inserted through the main or outer die and is gripped by the moving carriage. This is hauled along the bed of the mill by a massive chain, pulling the tube with it. At the initial movement the mandrel is advanced by the operator so that the inner die is within the main die; thus the bore and outer diameter are determined.

Heavy-gauge tubing of small bore, such as that used for oil-engine injection systems, may be drawn through the die by winding on a drum, instead of pulled in a straight line aIong the bed of the mill. This, and the very small sizes, are made without a mandrel, the use of which obviously would be impracticable, and, for the smallest tubes, diamond dies are employed. The formation of the effective surfaces of the dies is of the utmost importance.

To describe the many other processes as they deserve is unfortunately impracticable. Our object, here, has been to touch upon operations which may be described as representative, but an idea of the immensity and importance of the A. and P. organization may be gained from the facts that it provides employment for 3,500 workers and produces, on an average, a million ft. of tubing every week,