A New Cage for Roller Bearings.

Page 138

If you've noticed an error in this article please click here to report it so we can fix it.

THE cage for roller beatings, which is

the subject of the patent of S. K. F. Norma Aktiengesellschaft, of Caustatt, Germany (specification No. 280,942), is said to be an improvement on existing cages of the kind, as it will prevent the rollers from falling out when one of the races is removed. The specification points out that a cage which will not retain the rollers, when for any reason either the outer or inner ring is removed, Is a danger, as rollers of different sizes may be assembled from other bearings.

The invention appears to lie in the fact that the chambers formed in the cage for the reception of the rollers are of such a nature that they allow freedom for the roller when in place between the outer and inner ring, whilst the mouths of these chambers are contracted slightly so that the rollers cannot escape, although sufficient radial movement is allowed the rollers to permit clearing the flanges controlling them sideways.

Springs Designed to Reduce Rebound.

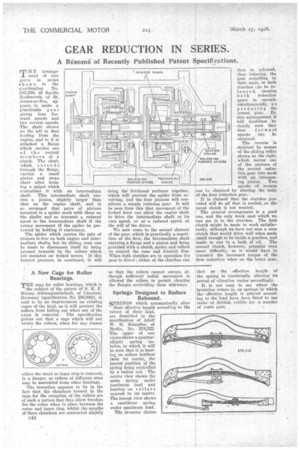

SPRINGS which automatically .alter their effective length according to the extent of their load, are described in the specification of Adolf W. H. Kiimpfer, of Berlin, No. 278,322. The upper of our views shows a quarterelliptic spring unladen, in which it will be seen that it is bearin on rollers farthest fuom its centre, the lateral position of the spring being controlled by a radius rod. The centre view shows the same spring under maximum load and bearing on rollers nearest to its centre. The lowest view shows a cantilever spring under maximum load.

The inventor claims that as the effective length of the spring is continually Altering its period of vibration .varies accordingly.

It is not easy to see where the invention comes in, as springs in which theeffective length is altered according to the load have been fitted to one make of British vehicle for a number of years past.