NOVEL FEATURES IN BODY .CONSTRUCTION.

Page 105

Page 106

Page 107

Page 108

If you've noticed an error in this article please click here to report it so we can fix it.

A • Record of Recent Progress in the Desigh of Passenger-vehicle Bodywork as Revealed by an Analysis of the Products of Several Prominent Makers., IN this article we do not propose to go into details regarding the construction of complete bodies of any type, but to treat only with certain aspects of their design, and particularly with the methods employed to combine strength with light weight, as, for instance, in the more extended use of corner brackets made in welded sheet-steel, the strengthening of pillars by the inclusion of metal inserts, etc.

Many of the points we shall bring out are of undoubted interest to all users and will go far to show that the coachbuilding industry is very much alive to the need for building bodies which will constitute as big an improvement over older patterns as do the chassis of to-day when compared with those of only a few years ago.

In many respects the present-day body, whether it be for the bus or coach, is a marvel of ingenuity. When looking at the skeleton of, say, a double-deck bus of the largest size, the uninitiated can hardly believe that its strength is sufficient to carry a load of 60 or more persons. Pillars, cross-bearers and roof sticks all look absurdly light, and yet the call is for bodies which shall weigh even less than those now being built!

There can be no rule-of-thumb methods in modern coach-building ; every part of the framework of a body has its particular function to fulfil and, usually, it performs. its task well.

It is fortunate that the latest chassis have much stronger frames than formerly. This prevents much of the weaving which previously occurred and has enabled coachbuilders to rely to a greater extent upon the strength of the chassis than upon rigidity in the body itself ; but more upon the subject of the chassis and its relation to the body will be found elsewhere in this issue.

It would be impossible in the space at our disposal to deal with the design of every make of body. We have, therefore, confined ourselves to dealing with the methods of a few well-known concerns, and shall continue to deal, from time to time, with others.

Our notes upon all-metal construction and accommodation for luggage are also included in other parts of this issue.

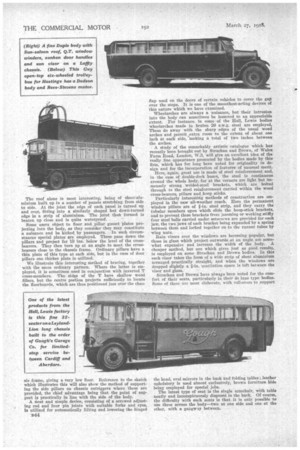

The visitor to the works of Hall, Lewis and Co., Ltd., Abbey Road, Park Royal, London, N.W.10, will find a tremendous amount to interest him, particularly in connection with light construction, as, for example, 20-seater bodies weighing 20i cwt.

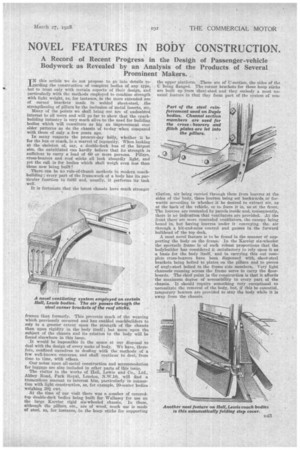

At the time of our visit there was a number of coveredtop double-deck bodies being built for Wallasey for use on the large Earner rigid six-wheeled chassis. In these, although the pillars, etc., are of wood, much use is made of steel, as, for instance, in the hoop sticks for supporting

the upper platform. These are of U-section, the sides of the U being flanged. The corner brackets for these hoop sticks are built up from sheet-steel and they embody a most unusual feature in that they form part of the system of yen tilation, air being carried through them from louvres at the sides of the body, these louvres being set backwards..or forwards according to whether it be desired to extract air, as at the back of the vehicle, or to force it in, as at the front. The louvres are concealed by panels inside and, consequently, there is no indication that ventilators are provided. At the front there are more concealed ventilators, the canopy being boxed in, but having louvres under it conveying the air through a hit-and-miss control and gauzes in the forward bulkhead of the top deck.

A most novel feature is to be found in the manner of supporting the body on the frame. In the Earlier six-wheeler the spectacle frame is of such robust proportions that the bodybuilder has considered it satisfactory to rely Upon it as a basis for the body itself, and in carrying this out complete cross-bearers have been dispensed with, sheet-steel brackets being bolted to plates on the pillars and to pieces of ang,l-steel bolted to the frame side members. Very light channels running across the frame serve to carry the floorboards. The chief point in the construction is that it affords the maximum degree of accessibility to every part of the chassis. It shouldrequire something very exceptional to necessitate the removal of the body, but, if this be essential, temporary bearers are provided to stay the body while it is away from the chassis. The roof alone is most interesting, being of sheet-aluminium built up in a number of panels stretching from side to side. At the joint the edge of each panel is turned up and over, fitting into a similarly shaped but down-turned edge in a strip of aluminium. The joint thus formed is beaten up close and is quite waterproof.

Some users object to floor and pillar gusset plates projecting into the body, as they consider they may constitute a nuisance and be kicked by passengers. In such circumstances special plates are employed. These pass down the pillars and project for 10 ins, below the level of the crossbearers. They then turn up at an angle to meet the crossbearers close to the chassis frame. Ordinary pillars have a thin plate of this type at each side, but in the case of door pillars one thicker plate is utilized.

We illustrate this interesting method of bracing, together with the more ordinary pattern. Where the latter is employed, it is sometimes used in conjunction with inverted T cross-members. The sides of the T have shallow wood fillers, but the centre portion projects sufficiently to locate the floorboards, which are thus positioned just over the elms

sis frame, giving a very low floor. Reference to the sketch which illustrates this will also show the method of supporting the side pillars on chassis outriggers where these are provided, the chief advantage being that the point of support is practically in line with the side of the body.

A neat and simple device, consisting of a screwed adjusting rod and four pin joints with suitable forks and eyes, is utilized for automatically lifting and lowering the hinged flap used on the doors of certain vehicles to cover the gap over the steps. It is one of the smoothest-acting devices of this nature which we have examined.

Wheelarches are always a nuisance, but their intrusion into the body can sometimes be lessened to an appreciable extent. For instance, in some of the Hall, Lewis bodies wheelarches made in beaten 20 s.w.g. steel are employed, These do away with the sharp edges of the usual wood arches and permit extra room to the extent of about one inch at each side, making a total of two inches between the arches.

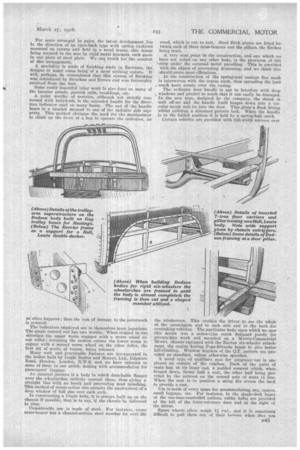

A study of the remarkably artistic catalogue which has recently been brought out by Strachan and Brown, of Wales Parra Road, London, W.3, will give an excellent idea of the really fine appearance presented by the bodies made by this firm, which has for long been noted for originality in design and for the incorporation of features of unusual merit.

Here, again, great use is made of steel reinforcement and, in the case of double-deck buses, the steel is continuous. around the whole body, for at the corners are light but immensely strong welded-steel brackets, which are bolted through to the steel reinforcement carried within the wood cross-hearers, pillars and hoop sticks.

Particularly interesting methods of construction are employed in the new all-weather coach. Here the permanent window pillars are of Fin, steel strip, and they carry the tubular members upon which slide the hoop-stick brackets, and to prevent these brackets from jamming or working stiffly four steel balls carried under setscrews are provided for each jaw, the two jaws of each bracket being expanded by a spring between them and locked together on to the runner tithes by wing nuts.

Rain visors over the windows are becoming popular, but those in glass which project outwards at an angle are somewhat expensive and increase the width of the body. A cheaper method, but one which gives just as good results, is employed on some Strachan and Brown bodies. In this each visor takes the form of a wide strip of sheet aluminium arranged practically straight, and when the windows are dropped slightly a g-in. ventilation space is left between the visor and glass.

Strachan and Brown have always been noted for the comfort of their seats, particularly in their de luxe type bodies. SOIT1P of these are most elaborate, with roll-ovens to support

the head, oval mirrors in the back and folding tables; leather upholstery is used almost exclusively, brown furniture hide being employed for special jobs.

The latest type of seat is the single armchair, with table neatly and inconspicuously disposed in the back. Of course, the difficulty with such seats is that it is only possible to use three across the body—two at one side and one at the other, with a gangway between.

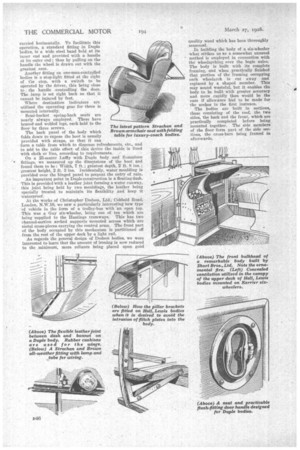

For seats arranged in pairs, the latest development lies in the direction of an open-back type with spring cushions mounted on canvas and held in a wood frame, this frame being secured to the seat by rigid metal brackets, each made in one piece of steel plate. We cm vouch for the 'comfort of this arrangement.

4 speciality is made of finishing roofs in lincrusta, the designs in many eases being of a most striking nature. It will, perhaps, be remembered that this system of finishing' was introduced by Strachan and Brown and was favourably received from the first.

Some really beautiful inlay work is also done on many of the interior panels, garnish rails, mouldings, etc. A point worthy of mention, although not strictly conCerned with bodywork, is the extended handle for the direction indicator used on many buses. The end of the handle bears in a bracket secured to one of the radiator side supports. This method obviates the need for the manipulator to climb up the front of a bus to operate the indicator, as so often happens ; thus the risk of damage to the paintwork is .reduced.

The indicators employed are in themselves most ingenious. The single control rod has two worms. When rotated in one direction the upper worm engages with a worm wheel on one roller ; reversing the motion causes the lower worm to engage with a second worm wheel on the other roller, the first set of gears, of course, being released. Many neat and practicable features are incorporated in the bodies built by Duple Bodies and Motors, Ltd., Edgware Road, 'Tendon, London, N.W.9, and we have referred to some of these in our article dealing with accommodation for passengers' luggage.

An unusual pattern is a body in which detachable flanges over the wheelarehes entirely conceal these, thus giving a straight line with no break and preventing mud splashing. This method of construction also permits the employment of a drop window of full size over each arch.

In constructing a Duple body, it is always built up on the chassis if possible, that is to say, if the chassis be delivered in time.

Considerable use is made of steel. For instance, every cross-bearer has a channel-section steel member let over the wood, which is cut to suit. Steel flitch plates are fitted between each of these cross-bearers and the pillars, the flitches being inset.

A very neat point in the construction, and one which we have not noted -on any other body, is the provision of felt strip under the external Metal panelling. This is provided with the object of preventing drumming, and we think this should prove most efficacious.

In the construction of the spring-seat casings fine mesh is interwoven with the coarse mesh, thus spreading the load , much More evenly over the casing.

The ordinary door handle is apt to interfere with drop windows and project so much that it can easily be damaged. In the new type, designed by the company, the shank is well off-set and the handle itself hinges down into a circular metal well let into the door. This gives a flush fitting whilst utilizing a standard pattern lock. When the handle is in the folded position it is held by a spring-ball catch.

Certain vehicles are provided with full-width mirrors over the windscreen. This enables the driver to see the whole of the passengers, and to each side and to the back for overtaking vehicles. The particular body upon which we saw this device was a sedan-type coach designed purely for private-hire work and mounted on a Morris-Commercial 30-cwt. chassis equipped with the Barton six-wheeler attachment, the engine having Pope-Ricardo heads to give better hill-climbing. Window winders of the Q.T. pattern are provided as standard, unless otherwise specified.

A novel type of auxiliary seat for gangway use is employed on certain of the coaches. Each of the pairs of seats has, at its inner end, a padded armrest which, when hinged down, forms half a seat, the other half being provided by the armrest on the second pair of seats in line. When the seat is in position a strap fits across the back to provide a rest.

Use is made of every space for accommodating, say, spares, small luggage, etc. For instance, in the single-deck buses of the one-man-controlled pattern cubby boles are provided at the left of the front-entrance door and at the right of the driver.

Spare wheels often weigh 11 cwt., and it is sometimes difficult to pull them out of their lookers when they -ara p45,

carried horizontally. To facilitate this operation, a standard fitting in Duple bodies, is a wide steel band held at its inner end and provided with a handle at its outer end ; thus by pulling on the handle the wheel is drawn out with the greatest ease.

Another fitting on one-man-controlled bodies is a stop-light fitted at the right of tie step, with a switch to be operated by the driver, this being close to the handle controlling the door. The lamp is set right back so that it cannot be injured by feet.

Where destination indicators are utilized the operating gear for these is mounted internally.

• Semi-bucket spring-back seats are nearly always employed. These have braced and welded legs, each held to the floor by three screws.

The back panel of the body which folds down to expose the boot is usually provided with straps, so that it can form a table from which to dispense refreshments, etc., and to add to the table effect of this device the inside is lined with cloth or lino, according to requirements.

On a 25-seater Laffly with Duple body and Sunsaloon

• fittings, we measured up the dimensions of the boot and found them to be : Width, 7 ft. ; greatest depth, 2 ft. 8 ins. ; greatest height, 2 ft. 3 ins. Incidentally, water moulding is provided over the hinged panel to prevent the entry of rain. An important point in Duple construction is a floating dash. This is provided with a leather joint forming a water runway, this joint being held by two mouldings, the leather being specially treated to maintain its flexibility and keep it waterproof.

At the works of Christopher Dodson, Ltd., Cobbold Road, Loudon, W.W.I°, we saw a particularly interesting new type of vehicle in the form of a trolley-bus with an open top. This was a Guy six-wheeler, being one of ten which are being supplied to the Hastings tramways. This has two channel-section arched supports mounted across which are nietal cross-pieces carrying the control arms. The front part of the body occupied by this mechanism is partitioned off from the rest of the upper deck by a light rail.

As regards the genera,1 design of Dodson bodies, we were interested to learn that the amount of ironing is now reduced to the minimum, more reliance being placed upon good quality wood which has been thoroughly seasoned.

In building the body of a six-wheeler what strikes us as a somewhat unusual method is employed in connection with the wheelatching over the bogie axles. The body is built with its complete framing, and when practically finished that portion of the framing occupying each wheelarch is cut away and replaced by a shaped member. This may sound wasteful, but it enables the body to be built with greater accuracy and more rapidly than would be the case if allowance had to be made for the arches in the first instance.

The bodies are built in sections, these consisting of the roof, the two sides, the back and the front, which are practically completed before being mounted together. The side members of the floor form part of the side sections, the cross-bars being framed in afterwards.