RECTION

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

GAME

01 perators of truckmounted fork-lifts tend to believe that with a service and a new set of wheels their little workhorses will last another decade. But Moffett neering of Coventry offers a better Its engineering staff will want to v what level of refurbishment your hine needs; they'll work out a price can afford and then invite you to e your choice.

lf course it is important for the cornI not to overstep that fine line ,teen selling new fork-lifts and rebuild)Id ones to near-new standards, but Mark Hignett believes he has struck ight balance: Some customers may )e able to afford a brand new one at 000, but they're usually attracted by *efurbished six-year-old machine ad at just £16,000, with a three-month ts and labour) warranty," he says.

lut Moffett's refurbishing work ;n't stop at the fork-lift—it can also up trucks or trailers to accept a <-mounted fork-lift.

. good example of this service ued a Richmond Motor Group 6x2 .or. It was dispatched to Euro Axles of astle for conversion to a rigid; body, was added by Roco Bodies of Bradford—two companies with a lot of experience in this type of conversion. Moffett fitted the mounting kit and the whole vehicle was resprayed in the customer's livery. It now sports a Mounty forklift and is earning its keep in its new role.

Total package

Moffett also buys selected semis of 19861995 vintage and customises them to suit clients' operations.

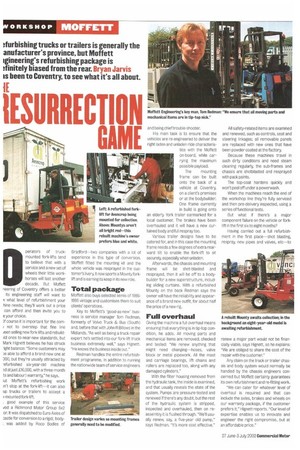

Key to Moffett's 'good-as-new' business is service manager Tom Redman, formerly of Volvo Truck & Bus (South) and, before that with John R Billows in the Midlands. "As well as being a truck repair expert he's settled into our fork-lift truck business extremely well,' says Hignett. "He knows the business inside out."

Redman handles the entire refurbishment programme, in addition to running the nationwide team of service engineers and being chief trouble-shooter.

His main task is to ensure that the vehicles are re-engineered to deliver the right laden and unladen ride characteristics with the Moffett on-board, while carrying the maximum possible payload.

The mounting frame can be built onto the back of a vehicle at Coventry, on a client's premises or at the bodybuilder. One frame currently in build is going onto an elderly York trailer earmarked for a local customer. The brakes have been overhauled and it will have a new curtained body and full respray too.

Various trailer designs have to he catered for, and in this case the mounting frame needs a few degrees of extra rearward tilt to enable the fork-lift to sit securely, especially when unladen.

Afterwards, the chassis and mounting frame will be shot-blasted and resprayed, then it will be off to a bodybuilder for a new superstructure, including sliding curtains. With a refurbished Mounty on the back Redman says the owner will have the reliability and appearance of a brand new outfit, for about half the price of a new rig.

Full overhaul

Giving the machine a full overhaul means ensuring that everything is in tip-top condition, he adds. All moving parts and mechanical items are removed, checked and tested: "We renew anything that might need changing—hoses, valve block or metal pipework. All the mast and carriage bearings, lift chains and rollers are replaced too, along with any damaged cylinders."

With the filter housing removed from the hydraulic tank, the inside is examined, and that usually reveals the state of the system. Pumps are pressure-tested and renewed if there's any doubt, but the rest of the hydraulic system is stripped, inspected and overhauled, then on reassembly it is flushed through. "We'll usually renew, say, a five-year old pump," says Redman, "It's more cost effective." All safety-related items are examined and renewed, such as controls, seat and steering linkages; all removable panels are replaced with new ones that have been powder coated at the factory.

Because these machines travel in such dirty conditions and need steam cleaning regularly, the sub-frames and chassis are shotblasted and resprayed with pack paints.

The top-coat hardens quickly and won't peel off under a powerwash.

When the machines reach the end of the workshop line they're fully serviced and then pre-delivery inspected, using a series of functional tests.

But what if there's a major component failure on the vehicle or forklift in the first six to eight months?

Having carried out a full refurbishment in the first place—shot blasting, respray, new pipes and valves, etc—to renew a major part woulo not be financially viable, says Hignett, so he explains: "We are obliged to share the cost of the repair with the customer."

Any claim on the truck or trailer chassis and body system would normally be handled by the chassis engineers concerned but Moffett certainly guarantees its own refurbishment and re-fitting work.

"We can cater for whatever level of overhaul is required and that can include the axles, brakes and wheels on our warranty package, if the customer prefers it," Hignett reports. "Our level of expertise enables us to innovate and engineer the right compromise, but at an affordable price."