Sparking plugs, 1

Page 63

If you've noticed an error in this article please click here to report it so we can fix it.

IN ORDER to complete the articles on ignition systems for spark ignition engines it is necessary to look at sparking plugs. A high voltage and intense spark must be produced in the highly compressed petrol-air mixture in the combustion chamber of an engine and it is the sparking plug's function to deliver this spark.

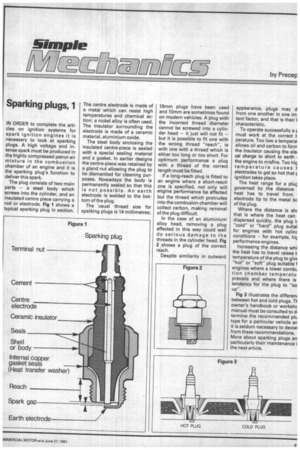

The plug consists of two main parts — a steel body which screws into the cylinder, and an insulated centre piece carrying a rod or electrode. Fig 1 shows a typical sparking plug in section.

The centre electrode is made of a metal which can resist high temperatures and chemical action; a nickel alloy is often used. The insulator surrounding the electrode is made of a ceramic material, aluminium oxide.

The steel body enclosing the insulated centre-piece is sealed with a special sealing material and a gasket. In earlier designs the centre-piece was retained by a gland nut allowing the plug to be dismantled for cleaning purposes. Nowadays the body is permanently sealed so that this is not possible. An earth electrode is welded to the bottom of the plug.

The usual thread size for sparking plugs is 14 millimetres; 18mm plugs have been used and 10mm are sometimes found on modern vehicles. A plug with the incorrect thread diameter cannot be screwed into a cylinder head — it just will not fit — but it is possible to fit one with the wrong thread "reach", ie with one with a thread which is either too long or too short. For optimum performance a plug with a thread of the correct length must be fitted.

If a long-reach plug is fitted to an engine where a short-reach one is specified, not only will engine performance be affected but the thread which protrudes into the combusion chamber will collect carbon, making removal of the plug difficult.

In the case of an aluminium alloy head, removing a plug affected in this way could well do serious damage to the threads in the cylinder head. Fig 2 .shows a plug of the correct reach.

Despite similarity in outward appearance, plugs may d from one another in one im tant factor, and that is their I characteristic.

To operate successfully a r must work at the correct t perature. Too low a ternperal allows oil and carbon to form the insulator causing the ele■ cal charge to short to earth , the engine to misfire. Too his temperature causes t electrodes to get so hot that r ignition takes place.

The heat range for a plus governed by the distance heat has to travel from electrode tip to the metal lac of the plug.

Where the distance is sh( that is where the heat can dispersed quickly, the plug it "cold" or "hard" plug suital for engines with hot cylinc conditions — for example, his performance engines.

Increasing the distance whi the heat has to travel raises t temperature of the plug to giv( "hot" or "soft" plug suitable f engines where a lower combt. tion chamber temperatu prevails and where there is tendency for the plug to "so up".

Fig 3 illustrates the differen4 between hot and cold plugs. TI• owner's handbook or workshc manual must be consulted to d, termine the recommended plu type for a particular vehicle an it is seldom necessary to deviat from these recommendations. More about sparking plugs an particularly their maintenance i the next article.