EHICLE.S SAVE MONEY [N FORESTRY

Page 69

Page 68

Page 70

Page 71

If you've noticed an error in this article please click here to report it so we can fix it.

By P. A. C. Brockingtou

HISTORICAL records of life in the Eastern Cotmlies in the 17th century mention the havoc that was caused by drifts of the sandy soil, particularly around Thetford. Cottages were sometimes inundated by the drifts, and one report recounts the loss of a coach and its team of horses. The sandy breck gave the district its character, and until recently stoutly resisted all attempts by farmers to exploit it for the economic production of crops.

Stabilization of the soil in this area was started by the Forestry Commission in 1922 with the planting of Scots pine in the first block of what is now Thetford Chase, a forest covering 44,000 acres and extending over 12 miles from north to south and from east to west. It is the Commission's largest forest in the Eastern Conservancy, and produces a greater tonnage of " thinnings " than any other Wooded area in the country,

.. Altholigh development of the forest is the first consideration, the sale `of-thinnings is a valuable source of revenue, the total. turnover lastyear -being approximately £325,000. About .1,000 tons of -poles (35,000 Cu. ft.) are delivered to the 30 acre depot at Brandon every • week, and a similar tonnage is dispatched' to industrialusers 'after processing. The stock •held-at. the depot:is .normally about 2,500 tons.

Gravelled Roads.

Of major importance to the economy of -pole collection in the forest is the .use of road vehicles In the rackways, adjacent to the removal areas, for direct loading of the poles, in preference to employing tractors and Sulky poletowing units for hauling them to the nearest tideway for later collection: Rackways are cut in the forest at intervals of two chains (132 ft.) and have a width of two rows of trees, which is equal to about 13 ft. 6 in. The poles are assembled in heaps in the rack ways to facilitate collection. Many of the ricleways are gravelled roads which were originally „built to provide 'firebreaks.

Pole haulage by tractor from rackway to rideway involves double-handling, and the tractor speed is lower than that of a road vehicle. The method is no longer used in Thetford. Chase unless thereare windfalls of larger trees that cannot be loaded on road vehicles.

Although the trees are originally cut to ground level, subsidence of the soil several inches below the tops of the stumps creates a serious hazard' in respect of tyre damage and shock loading Of the transmission gear, but in favour D24

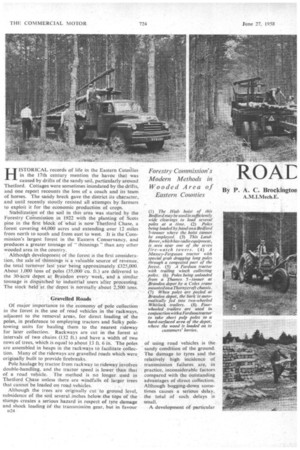

(1) The Hiab hoist of this Bedford May be used in sufficiently wide clearings to load several poles at a time. (2) Poles being loaded by:hand ona Bedford5-tonner where the hoist cannot, be employed. (3) This LandRover, which has radio equipment, is _seen near one of the Seven fire-watch towers. (4) A Massey-Ferguson tractor with special grab dragging long poles through a congested part of the forest. (5) A Fort/son tractor -with trailing winch collecting poles. (6) Poles being unloaded from a Thames .5former at Brandion depot by a Coles crane mountedonaThornYcroft chassis.. (7) When poles are peeled at Brandon depot, the bark is-automatiCally fed into two-wheeled Whitlock trailers. (8) Fourwheeled trailers are used in conjunction with a Fordson tractor to take short pulp poles to a hard-surfaced area of the depot, where the wood is loaded on to

customers' lorries.

of using road vehicles is the sandy condition of the ground. The damage to tyres and the relatively high incidence of transmission failures are, in practice, inconsiderable factors compared with the outstanding advantages of direct collection. Although bogging-down sometimes causes a serious delay, the total of such delays is small.

A development of particula r

importance which virtually enabled road vehicles to be directly employed for pole collection was the introduction some six years ago of extendible two-wheeled trailers, designed by the Commission and built by the Taskers company. These are used in conjunction with a standard type of 5-ton long-wheelbase lorry equipped with the Swedish-made Hiab hoist. Hydraulically operated by a pump driven from a power take-off on the gearbox, the

hoist is mounted behind the cab and has a capacity of 10 cwt.

The trailer is attaChed to a draw-bar eye on the rear cross member of the lorry, and the Poles are loaded on a turntable.

mounted bolster on the vehicle platform and a similar bolster on the trailer, the poles being held in place by bolster pins. Because the drawbar eye is behind the axis of the lorry turntable, relative movement between the poles and the bolsters is inevitable when the vehicle is making a sharp turn, but this is not a practical drawback. The outfit handles as well as a conventional articulated trailer outfit.

Of particular importance to the work of the forestry personnel in contending with load variations is the facility with which a vehicle bolster can be removed. This enables the lorry to be employed as a solo machine at short notice. The trailer has a rated capacity of 4 tons, and it is normally possible to carry a combined load of 8 tons.

The trailer is based on a robust box-section backbone member and the bogie unit, complete with bolster, can be extended 8 ft., location of the unit being provided by a knock-out tapered peg. Other details of the trailer include 7.50-20 tyres, Clayton-Dewandre vacuum brakes, semi elliptic springs and quick-release bolster pins.

On account of their comparatively small diameter and weight, thinnings up to 30 ft. long can be loaded by three men without the use of the hoist, but this equipment enables two loaders to do the work of three, and its use increases the number of poles: that can be loaded on the vehicle. When they are loaded manually, the poles cannot be lifted over the trailer bolster pins, and when a second pin is required to prevent sideways slippage loading cannot be continued.

Six trailers of this type are employed in combination with an equal number of Bedford 5-ton long wheelbase drop-sided lorries, all of which are equipped with Hiab hoists. Whether or not the trailer is used depends upon the length and weight of the poles, lighter poles of limited length being loaded on the lorry with the aid of the hoist by one man. An overall pole length of 35-40 ft. can be accommodated on the trailer outfit.

Also included in the collection fleet are two Eagle articulated pole wagons of the conventional type, which are hauled by Austin K.4 short-wheelbase tractors. These vehicles enable long slender poles to be manually loaded and heavy poles to be winch-loaded by oil-engined tractors fitted with Boughton winching gear.

When the replacement of older tractors has been completed, the forestry tractor fleet will comprise 11 Ferguson 35 oil-engined units. The tractors are fitted with a timbergrab attachment, developed by the Commission and built by a local concern. With the aid of this machine, the driver can extract butts without assistance from other workers.

Remaining lorries in the road-transport forestry fleet comprise seven Thames Trader 4D 5-tonners and the older type of Thames 7V 5-ton vehicle powered by VS petrol engines, which are additional to one of each model employed for nursery work. The 4D vehicles mainly carry finished poles from the depot to customers' premises, and the nursery lorries are regularly engaged on long-distance runs, including the transport of hop-waste fertilizer from the breweries. The 4D is particularly economical for this long distance work.

Three head foresters and most of the foresters in charge of the 15 Thetford Chase beats are provided with service vans for supervising silvicultural operations. Eight vans include the Bedford CA model which will eventually be the only type used.

All the forestry lorries are returned to the main base at San ton Downham at the end of the day after covering an average of more than 100 miles. Runs vary between a round trip of 5 miles to a maximum of about 40 miles between the collection point and the Brandon depot, 3 miles from Santon Downham. The longer distances covered in a day sometimes exceed 150 miles.

Tests have shown that an oilengined lorry engaged on forest collections operates with a fuelconsumPtion rate of 15-17 m.p.g. 'compared with a rate of about 8 m.p.g. averaged by the petrolengined vehicles. The favourable economy of the oil engine offers such an outstanding cost saving that the unit will probably be specified when replacements are made despite the disadvantage of the oiler in the forest with regard to traction difficulties.

The ability of the V8 engine to oPerate evenly at low r.p.m. is particularly useful when the vehicle is operating in the rackways. It is considered that a six-cylindered oil engine would offer traction advantages over four-cylindered types of the same output, and that a five-speed gearbox would enable traction to be improved.

The rear wheels of all vehicles engaged on pole collection are fitted with eross-country tyres of various makes to improve traction, whilst the front wheels are equipped With the standard type. A fair proportion of the -tyres is fit for retreading after the treads have been worn smooth.

Common causes of transmission trouble include the fracture of half-shafts and wheel stud, and less frequently. the failure of propeller shafts. Occasional but more costly troubles. include differential failure.

• Trees are felled manually by a forestry Wcirker with a bOW saW and the butts are often removed by the same -means: After the tops of the longer trees have been cut off, •the poles are stacked in separate piles according to specification. The butts are stored in the forest and are ncirmally collected from the forest by manufacturers for the production of box-Wood, or by the Thetford Chase transport department for delivery to customers. The turnover of the Brandon

depot does not, therefore, represent the total output of the forest.

Selected timber is peeled at Brandon depot for the production of mine props, poles of smaller diameter being cut to form fencing stakes And so on. The remainder is purchased for pulp-making by paper manufacturers and for the production of wall-board, harvest Nies and bean sticks. More than •half of the poles are converted into pit, props, transport to National Coal Board mines being by rail or in contractors' vehicles.

The same kind ofhighly detergent lubricating oil of M.D. specification is used for both petroland oil-engined vehicles, the viscosity grade depending on the• vehicle makers' recommendations. The oil is delivered in bulk and employing one type greatly simplifies storekeeping. Engine starting has improved since its introduction a short time ago and it is considered that the properties of the oil will increase engine life.

A wide difference. between •the oil-change` periods for petrol and oil engines offers an interesting contrast to the policy of the average operator. The lubricant of petrol engines is changed after 2,000 miles, whilst an oil engine normally completes 5,000 miles between changes.

Overhaul Programme •

Drivers return their vehicles to . the Santon Downham • depot earTy on Friday afternoons to service their vehicles under the supervision of a staff of three qualified fitters. Overhauls and replacements are performed according to the decisions of the transport manager, who keeps a detailed record of repair work and is normally able to forecast what overhauls will be necessary, apart from emergency repairs, for some months ahead.

Van engines are fitted with new piston rings when oil consumption becomes excessive, but the larger petrol engines are normally replaced by factory-reconditioned units in preference to performing an intermediate overhaul. The service life of Bedford petrol engines averages 80,000 miles, whilst the V8 units are replaced after about 40,000 miles. So far none of the oil engines has been replaced, and it is. considered that they will continue to operate satisfactorily for a substantially greater mileage than the petrol -engines. . The workshops are fully equipped for all routine overhauls and small body repairs.

Fire-fighting is a "normal emergency" in the summer months (seven watch towers are manned in seasons of high fire danger), and two fire tenders based on Bedford ex-W.D, `QL chassis are Stationed at the Santon Downham depot in readiness.for a call from any part of the forest. The fire warden's office is also located at Santon Downham, and a fleet of five Land-Rovers, fitted with water pumps, can be employed for fire-control duties. Two of these vehicles are equipped with G.E.C. two-way •15-mile radio sets.