HINTS ON MAINTENANCE.

Page 28

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

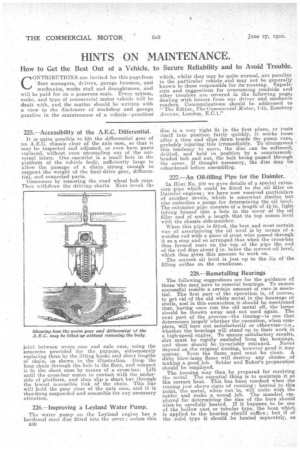

225.—Accessibility of the A.E.C. Differential.

It is' quite possible to lift the differential gear of an A.E.C. chassis clear of the axle ease, so that it may be inspected and adjusted, or even have parts replaced, without even uncoupling any of the universal joints. One essential is a small hole in the platform of the vehicle body, sufficiently large to allow the passage of a chain strong enough to support the weight of the final-drive gear, differential, and connected parts.

Commence by removing tho road wheel hub caps. Then withdraw the driving. shafts. Next break the

joint between worm case and axle case, using the setscrews provided for the purpose, subsequently replacing them by the lifting hooks and short lengths of chain, as shown in the illustration. Drop the long chain through the hole in the floor, and connect it, to the short ones by means of a cross-bar. Lift until the cross-bar comes in contact with the underside of platform, and then slip a short bar through the lowest accessible link of the chain. This bar will hold the gear clear of the axle case, and it is thushung suspended and accessible for any necessary attention.

226:—Improving a Leyland Water Pump.

The water pump on the Leyland engine has a hardened steel disc fitted into the cover ; unless this B30 disc is a very tight fit in the first place, or rusts itself into position fairly quickly, it works loose after a time and slips down beside the pump vane, probably injuring this irremediably. To circumvent this tendency to move, the disc can be softened, drilled, and held in position by a countersunkheaded bolt and nut, the bolt being passed through the cover. If thought necessary, the disc may be rehardened before assembling.

227.—An Oil-filling Pipe for the Daimler.

In Hint No. 219 we gave details of a special extension pipe whiCh could be fitted to the oil filler on Daimler engines; we have now received particulars of another device, which is somewhat similar but also embodies a gauge for determining the oil level. The extension pipe consists of a length of light tubing brazed into a hole in the cover of the oil filler and of such a length that its top comes level with the chassis side-member.

When this pipe is fitted, the best and most certain way of ascertaining the oil level is by means of a wooden rod with a piece of stout wire passed through it as a stop and so arranged that when the cross-bar thus formed rests on the top of the pipe the end of the rod dips about in. below the correct oil level, which thus gives this amount to work on.

The correct oil level is just up to the lip of the filling orifice on the crankcase.

228.—Remetalling Bearings

The following suggestions arc for the guidance of those who may have to rernetal bearings. To ensure successful results a certain amount of care is essential. The first part of the operation is' of course, to get lid of the old white metal in the housings or shells' and in this connection it should be mentioned that, having once run the old metal off, the latter should •be thrown away and not used again. The next part of the process—the tinning—is one that determines largely whether the operation, when complete, Will turn out satisfactorily or otherwise—i.e., whether the (bearings will stand up to their work in a high-speed engine. To ensure satisfactory results, dirt must be rigidly excluded from the housings, and these should be invariably retinned. Never depend on the original tinning, however good it may appear. Even the flame used must be clean. A dirty blow-lamp flame will destroy any chalice of making a good job. Solder and Baker's preparation should be employed.

The housing may then be prepared for receiving the metal. The essential thing is to maintain it at the correct heat. This has been reached when the tinning just shows signs of running ; heated to this point, the metal, when run in, will unite with the solder and make a sound job. The mandrel employed for determining the size of the bore should alscs be carefully heated. If it happens to be one of the hollow east or tubular type, the heat which is applied to the bearing should suffice ; but if of the solid type it should be heated separately, as

otherwise the white metal may be cooled off too rapidly.

In heating the metal to be run in, a reliable test of the temperature is to use a shaving of wood. At the correct heat the metal should brown and not char the shaving. If a purplish skin shows on top of the metal in the crucible it has been overheated, and must be allowed to cool slightly so that when the skin has been removed the surface remains perfectly bright. Stir the metal well before proceeding to run it in, and, having filled the housRag, take a

piece of thin wire and dip it gently in the metal whilst this is still in its molten state. Keep the blow-lamp flame playing on the upper part of the housing, so that should the white metal show any signs of subsiding more can be added. The job will have been successful if the metal does not show hard and brittle. This can easily be ascertained by using a scraper, as, in taking a scraping, the metal should tend to peel. If it should be too hard it will be necessary to repeat the operation and to observe more care.