THE LEYLAND-TROJAN UTILITY VEHICLE.

Page 24

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

Economy in Running and Maintenance the Keynote of the Design.

LAST WEEK we were able to give a résumé of the leading features of dip Trojan vehiele, together with notes on its performance during a trial trip, but time did not permit the inclusion of details of ha construction, nor the preparation of illustrations. We therefore deal with it more fully in this article, and from the point of view that, although at present built as a passenger ear, it should prove an eminently suitable vehicle for the commercial traveller, QS it is remarkably cheap to run, does not suffer from the inconvenience of punctures, is practically foolproof, and can be driven by ,a novice after a few minutes' duration, whilst its cost is only £230.

The power unit is accessibly situated horizontally under the driver's seat and floorboards, with the cylinder head pointing towards the, front and the crankshaft positioned across the chassis. At the off-side end of the crankshaft is a fairly large flywheel, and from the periphery of this, and radiating to a special anchor plate forming a portion of the two-speed epicyclic gear, is a number of coil tension springs which 'form a spring or cushion drive.

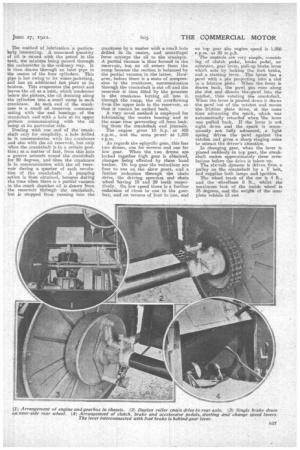

Between the gearbox and the driving sprocket for the silent or Duplex-roller single chain anal drive, is a pair of skew gears giving a constant reduction of four-to-one. The chain runs on a chain wheel. 'bolted to the off-aide rear wheel and consequently driving both wheels, as the two are connected together by a solid, splined axle shaft running on hall bearings in the fixed axle tube. At the near side the crankshaft is extended and projects into a special locker on the near-side running board_ On its end is carried the timer for the Delco-Remy coil ignition set.

The bonnet between the gilled tubular 826

radiator and the dash contains nothing but the round tank holding over 7 gallons of petrol, the steering gearbox with its pinion meshing with an internal-toothed ring, and the simple Hounsfield caxburetter with its inlet muffle to silence. the incoming air and also to catoh any petrol spray which may be ejected.

The body is built of blued steel plate pressed throughout, and each of the backs of the front seats is mounted on a vertical spindle fitting into clips behind the seats, -so that the backs can he swivelled round or removed altogether with the greatest ease, in order to allow access to the rear 'portion of the body, which has no doors.

It will be noted that the body is somewhat short and that there is no overhang. This is in order to distaibuto the weight as evenly as possible between the two. axles, and although the rear seats look somewhat cramped they a r actually quite coon, forta.ble and there is plenty of leg room. The rear seats can easily be removed 20 that the space can be used for carrying light samples, etc. The hood is neat and effective, It has one upright on which slide two horizontal hoop sticks in exactly the same way as the staY's of an umbrella.

An miasmal feature is that the preeeed-steel wheels are shod with 28-in. by 2-in, solid tyres. Up tothe present, after running many thousands of miles on several cars, the tyre costs work out at one-sixth pence per mile, whilst the petrol consumption is 40 m.p.g.

The power unit is a particularly in teresting type, embodying the twostroke cycle. It has four cylinders of bore and 4-in. "stroke, arranged in the form of a square the upper and lower combustion chambers at each side being connected together by a passage.

In each pair of cylinders the inlet port is in the upper cylinder and the exhaust port in the lower, thus a uniflow action .is obtained. Commencing the cycle of operations with the pistons at the top of the cylinders and at the moment of the exploeion, the two pistons travel down the cylinders, each being fastened to one arm of a forked connecting rod. Owing to the angularity of this trod, one piston travels faster than the other on the down stroke (in this .case it is the lower piston), and thus opens the exhaust port before the Upper piston opens the inlet part.

On the return stroke, the exhaust ,pert is closed slightly before the inlet port, and as the pistons travel along the cylinders compressing the charge, the upper piston moves faster than the lower, and thus part of the compressed mixture in the upper cylinder is ,forced through the port between the two combustion chambers. The sparking plug in the -tipper cylinder then ignites the charge, and a portion of the flaming gas is projected through the pert just re. ferred to, thus turbulence is present in the mixtore both before and during combustioe.

Meanwhile, as the pistons near the top. of the stroke, the transfer port between the inlet pipe and the crankcase is opened' by the skirt, of a piston.

• Owing to the uniflow action and to the eize of the communioating port between the combustion chambers, the loss of mixture through the exhaust Port is very slight.. Taking as a comparison. the less in the ordinary twostroke engine as being 20 per cent., the loss in this engine is only 4 per cont.

Although the arms of each connecting rod are of the same length, the angularity of the rod causes them to be sprung out slightly by thtapistons.

.The method of lubrication as particularly interesting. A measured quantity of oil is mixed with the petrol in the tank, the mixture being passed through the carburetter in the ordinary way. It is then drawn through an inlet -pipe in the centre of the four cylinders. This pipe is hot owing to its water-jacketing, and has an additional hot plate at its bottom. This evaporates the petrol and leaves the oil as a mist, which condenses below the pistons, the oil draining along the cylinders into a small sump in each crankcase. At each end of the crankcase is a small oil reservoir communieating with the end bearings of the crankshaft and with a hole at its upper portion communicating with the oil sump at its particular side.

Dealing with one end of the crankshaft only for simplicity, a hole drilled in it communicates with the crankcase and also with the oil reservoir, but only When the crankshaft is in a certain position; as a matter of fact, from this hole a groove extends round the crankshaft for 90 degrees, and thus the crankcase is in communication with the oil reservoir during a quarter of each revolution of the crankshaft. A pumping action is then obtained; because during the time when there is a partial vacuum in the crank chamber oil is drawn from the reservoir through the crankshaft, but is stopped from running into the

crankcase by a washer with a small hole drilled in its centre, and centrifugal force conveys the oil to the crankpin. A partial vacuum is thus formed in the reservoir, but no oil enters from the sump because the suction is balanced by the partial vacuum in the latter. However, before there is a state of compresthon in the crankcase, communioation through the crankshaft is cut off and the reservoir is then filled by the pressure in the crankcase forcing oil into it through the sump, the oil overflowing from the upper hole in the reservoir, so that it cannot be sucked back.

A very novel method is employed for lubricating the centre bearing • and at the same time preventing ail from leaking from the crankshaft end journals.

The engine gives 10 h.p. at 400 r.p.m., and the same power at 1,200 r.p.m.

As regards the epicyclic gear, this has two drums, one for reverse and one for low gear. When the two drums are locked together high gear is obtained, changes being effected by three band brakes. On top gear the reductions are four to one Cu the skew gears, and a further reduction through the chain drive, the driving sprocket and chain wheel having 19 and 29 teeth respectively. On low speed there is a further reduction of three to one in the gearbox, and on reverse of four to one, and

on top gear the engine speed is 1,000 r.p.m. at 20 m.p.h. •

The controls are very simple, consist, ing of clutch pedal, brake pedal, accelerator, gear lever, pull-up brake lever Which acts by locking the foot brake, and a starting lever. . The latter has a pawl with a pin projecting into a slot in a friction plate. When the lever is drawn back, the pawl pin runs along the slot and directs the spawl into the ratchet, thus rotating the cearikehaft. When the lever is pushed down it draws the pawl out of the ratchet and moves the friction plate down, at the same time advancing the spark, which was automatically retarded when he lever was pulled back. If the lever is not Tight down and the spark is consequently not fully 'advanced, a light, spring drives the pawl against the ratchet and gives a sharp ringing noise to attract the driver's attention.

In changing gear, when the lever is placed suddenly an top gear, the crankshaft makes approximately three revolutions before the drive is taken up.

The six-volt dynamo is driven from a pulley on the crankshaft by a V belt, and supplies both lamps and ignition.

The wheel track of the car is 4 ft., and the wheelbase 8 ft., whilst the maximum lock of the inside wheel is 35 degrees, and the weight of the complete vehicle 13 cwt