Valve Gear.

Page 26

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

Contributed by an Engineer-in-Charge.

The working of valves and valve gear on steam wagons and tractors is not so thoroughly understood by the average driver as it should be; many men are reluctant to make the slightest alteration, owing to the fact that they are given to understand that it is shrouded in mystery, and only to be tackled by men experienced in that class ot work. I must admit that my own early endeavours to master the action of valves and gears were beset with difficulties, but, Once thoroughly understood, the ordinary slide-valves and gears are, in fact, very simple, although some forms of valve-gear present greater difficulty to the beginner. In " TFIE COMMERCIAL MOTOR of the loth of January, I explained the action of slide valves in a simple manner, capable of being understood by any man of ordinary intelligence. In the present article, I shall deal with the gear whereby the slide-valve obtains its motion in either direction. A careful study will enable any man to tackle the job of remedying any defects or making adjustments, without the assistance of outside help, which, in many cases, is not obtainable.

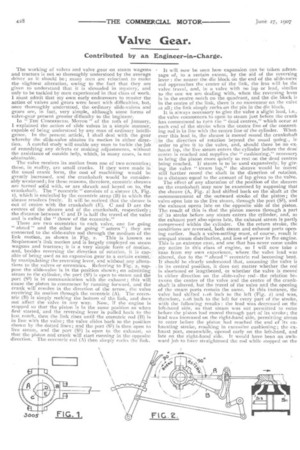

The valve receives its motion from one of two eccentrics.; these, in reality, are small cranks. If they were made in the usual crank form, the cost of machining would be greatly increased, and the crankshaft would be considerably weakened; for these reasons, therefore, eccentric sheaves are turned solid with, or are shrunk and keyed on to, the crankshaft. The " eccentric " consists of a sheave (A, Fig. I), which is encircled by the eccentric strap (B) in which the sheave revolves freely. It will be noticed that the sheave is out of centre with the crankshaft (E). C and D are the centres of the sheave and of the crankshaft, respectively ; the distance between C and D is half the travel of the valve and is called the " throw of the eccentric.."

There are two eccentrics to each valve, one for going " ahead " and the other for going " astern "; they are connected to the slide-valve rod through the medium of the

link motion, as shown in Fig. 2. This is known as Steplaenson's Link motion and is largely employed on steam wagons and tractors; it is a very simple form of motion, and, besides reversing the direction of rotation, it is capable of being used as an expansion gear to a certain extent, by manipulating the reversing lever, and without any alterations to the valves or eccentrics. Referring to Fig. 2, suppose the slide-valve is in the position shown; on admitting steam to the cylinder, the port (Si) is open to steam and the port (S5) is in communication with the exhaust; this will cause the piston to commence by running forward, and the crank will revolve in the direction of the arrow, the valve receiving its motion through the eccentric (A). The eccentric (B) is simply rocking the bottom of the link, and does not affect the valve in any way. Now, if the engine is stopped so that the piston is in the same position as when first started, and the reversing lever is pulled hack to the last notch, then the link rises until the eccentric rod (B) is in line with the valve; the valve slides back to the position shown by the dotted lines; and the port (52), is then open to live steam, and the port (51) is open to the exhaust, so that the piston and crank will start running in the opposite direction. The eccentric rod (A) then simply rocks die link. It will now be seen how expansion can be taken advan. tage of, to a certain extent, by the aid of the reversing lever : the nearer the die block on the end of the slide-valve rod approaches the centre of the link, • the less Vill be the valve travel, and, in a valve with no lap or lead, similar to the one we arc dealing with, When the reversing lever is in the centre notch on the quadrant, and the die block in the centre of the link, there is no movement on the valve at all; the link simply rocks on the pin in the die block. It is always necessary to give the valve a slight lead, i.e., the valve commences to open to steam just before the crank has commenced to turn the " dead centres," which occur al each end of the stroke when the centre line of the connecting rod is in line with the centre line of the cylinder. Whatever this lead is, the sheave is moved round the crankshaft in the direction of rotation beyond the usual 9odeg., in order to give it to the valve, and, should there be no exhaust lap, the live steam enters the cylinder before the dead centre is reached and supplies the " cushioning," necessary to bring the piston more quietly to rest on the dead centres being reached. If steam is to be used expansively; by giving the valve " 'steam lap," the sheave would be moved still. further round the shaft in the direction of rotation, to a distance equal to the amount of lap given to the valve. The effect of any alteration of the position of the sheaves on the crankshaft may now be examined by supposing that the .sheave (A, Fig. 2) had shifted back on the shaft at the commencement of the outward stroke of the piston; thE valve open late to the live steam, through the port (Si), and the exhaust opens late on the opposite side of the piston. The result of this is that the piston moves through a part of its stroke before any steam enters the cylinder, and, as the exhaust port also opens late, the exhaust steam is partly compressed within the cylinder. On the return stroke, tht conditions are reversed, both steam and exhaust ports open. ing earlier. Such a valve-setting must, of course, result in unequal steam distribution, and loss of power in The engine. This is an extreme case, and one that has never come under my notice in this class of engine, so I will now take a case from my own experience, where the valve lead was altered, due to the " ahead " eccentric red becoming bent It s;houlci be clearly understood that, assuming the valve is . in its central position, it does not matter whether the rod is shortened or lengthened, or whether the valve is moved in either direction on the slide-valve rod—the relation between the centre of the valve and the centre of the crankshaft is altered, but the travel of the valve and the opening of the steam ports remain the same. In this instance, the valve had shifted 1-16 inch to the left (Fig. 2) and was, therefore, i-e6 inch to the left for every part of the stroke, with the following results : the lead was decreased on the left-hand side, so that steam was not permitted to enter before the piston had moved through part of its stroke; the lead was increased on the right-hand side, permitting steam to enter before the piston had reached the end of its exhausting stroke, resulting in excessive cushioning ; the exhaust port, meanwhile, opened early on the left-hand, and late on the right-hand side. It would have been an awkward job to have straightened the rod while stopped on the

road-side ; I, therefore, took out two washers from the gland studs, and placed them over the studs in the eccentric straps, between the straps and the rod. The valve was, thus, brought back, approximately, to its correct position, until an opportunity offered to put the rod straight.

The importance of having the pins and die block in good condition will be apparent, as any play will affect the opening of the ports at the proper time, and a very little difference in the opening of the Steam and exhaust ports in this class of engine—owing to the high speed at which they run—will make a considerable difference to the coal, bill in the course of a year. A good plan to adopt, when the valve has been properly set, is to make a centre dot on the slide-valve rod, and another on some fixed part of the engine, e.g-., the rod guide; then set a pair of dividers to correspond with these two dots and transfer them to the steam chest cover or the side of the guide bars, SO that at any time you can set the dividers to the two permanent dots and try them on the two dots on the slide red and guide; if they corrEspond, you may be sure the position of the slide-valve has not altered through the sheaves shifting, or through wear on the eccentric straps. Any alteration can be made without breaking the steam-chest-cover joint, by putting in, or taking out, a liner under the foot of the eccentric rod. If it is not a screwed rod, 110 liner would be required for the adjustment. It will be apparent that the position of the crosshead on the guide bars will have to be the same, at the time of any subsequent trial, as it was when the marks were first put on ; fine lines should, therefore, be scribed on the side of the crosshead and guide bars.