Fine today. What about tomorrow?

Page 122

Page 123

If you've noticed an error in this article please click here to report it so we can fix it.

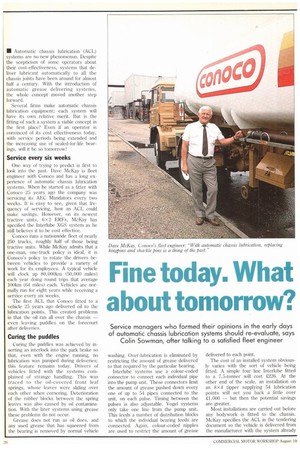

Service managers who formed their opinions in the early days of automatic chassis lubrication systems should re-evaluate, says Colin Sownnan, after talking to a satisfied fleet engineer

• Automatic chassis lubrication (ACL) systems are no new phenomenon. Despite the scepticism of some operators about their cost-effectiveness, systems that deliver lubricant automatically to all the chassis joints have been around for almost half a century. With the introduction of automatic grease delivering systems, the whole concept moved another step forward.

Several firms make automatic chassis lubrication equipment; each system will have its own relative merit. But is the fitting of such a system a viable concept in the first place? Even if an operator is convinced of its cost effectiveness today, with service periods being extended and the increasing use of sealed-for-life bearings, will it be so tomorrow?

Service every six weeks

One way of trying to predict is first to look into the past. Dave McKay is fleet engineer with Conoco and has a long experience of automatic chassis lubrication systems. When he started as a fitter with Conoco 25 years ago the company was servicing its AEC Mandators every two weeks. It is easy to see, given that frequency of servicing, how an ACL could make savings. However, on its newest tractive units, 6x2 Eta's, McKay has specified the Interlube XGS system as he still believes it to be cost effective.

Conoco runs a nationwide fleet of nearly 250 trucks, roughly half of those being tractive units. While McKay admits that a one-man, one-truck policy is ideal, it is Conoco's policy to rotate the drivers between vehicles to provide a variety of work for its employees. A typical vehicle will clock up 80,000km (50,000 miles) each year doing round trips that average 100km (64 miles) each. Vehicles are normally run for eight years while receiving a service every six weeks.

The first ACL that Conoco fitted to a vehicle 25 years ago delivered oil to the lubrication points. This created problems in that the oil ran all over the chassis — even leaving puddles on the forecourt after deliveries.

Curing the puddles

Curing the puddles was achieved by inserting an interlock into the park brake so that, even with the engine running, no lubrication was pumped during deliveries; this feature remains today. Drivers of vehicles fitted with the systems coniplained of strange handling. This was traced to the oil-covered front leaf springs, whose leaves were sliding over each other when cornering. Deterioration of the rubber blocks between the spring leaves was also caused by oil contamination. With the later systems using grease these problems do not occur.

Grease does not run as oil does, and any used grease that has squeezed from the bearing is removed by normal vehicle washing. Over-lubrication is eliminated by restricting the amount of grease delivered to that required by the particular beating.

Interlube systems use a colour-coded connector to connect each individual pipe into the pump unit. These connectors limit the amount of grease pushed down every one of up to 54 pipes connected to the unit, on each pulse. Timing between the pulses is also adjustable. Vogel systems only take one line from the pump unit. This feeds a number of distribution blocks to which the individual bearing feeds are connected. Again, colour-coded nipples are used to restrict the amount of grease delivered to each point.

The cost of an installed system obviously varies with the sort of vehicle being fitted. A simple four line Interlube fitted to a 7.5-tonner will cost £226. At the other end of the scale, an installation on an 8x4 tipper supplying 54 lubrication points will set you back a little over £1,000 but then the potential savings are greater.

Most installations are carried out before any bodywork is fitted to the chassis. McKay specifies the ACL in the tendering document so the vehicle is delivered from the manufacturer with the system already installed. This means that tractive units can work from day one and are not left standing in the yard awaiting a retrofit.

McKay sees savings achieved by fitting an ACL in three areas; the cost of spares, related down-time when replacing worn parts and the reduced service times as fitters do not need to grease dozens of grease nipples. On the first point McKay says that "replacing kingpins and shacklepins is a thing of the past". Except for the odd rogue pin, Conoco's vehicles complete their eight years of service without any such replacements.

True cost becomes evident

One of Conoco's fitters used to work for a tipper operator. During that time he was replacing two kingpins per vehicle per year. The operator would not fit ACL as he considered it "too messy". Looking at the price of new kingpins and costing the time to fit them would give some idea of the direct expense involved in their replacement. Add to this the loss of income while the vehicle is in the workshop, and the true cost becomes evident.

As to the reduction in service time, this is not as easy to quantify. McKay estimates that to do a thorough job of manually greasing a tractive unit would take up to an hour. This may seem a long time, but there is always the odd nipple that is blocked and needs heating or removal to clear it and this pushes up the average times a disproportional amount.

If an hour of workshop time costs between 213 and 219 and a service is carried out every six weeks, there is a saving of between 2112 and 2164 per year (but use your own hourly rate). However, it is McKay's view that service intervals need to he kept to every four weeks if manual greasing is being relied upon — this raises the potential savings to between 2169 and 2247 per year.

This point of view has credibility not only because of McKay's experience but also because of what is happening on the Continent. Mercedes-Benz has started to fit Vogel ACL systems as standard to its Powerliner II, 1726 and 1722 models. These are having their service periods extended up to a maximum of 45,0001an (28,125 miles); or six months, depending on the type of work being done.

A negative side to any ACL system is that it cannot lubricate all of the greasing points. This demands that the fitters remain diligent in greasing universal joints, propshaft sliders and the like. McKay also believes that all vehicles in the fleet need to be equipped with ACL systems as the odd one that is not fitted is in danger of having its greasing overlooked by fitters who are used to ACL-equipped trucks.

When all the cost implications are taken into account, McKay estimates that such systems pay for themselves in two and a half years. So if the 21,000 cost of fitting a system to a tractive unit is recovered in two and a half of the eight years of their time with Conoco, the maintenance costs have been reduced by about 23,200 — a saving of 22,200.

These figures are fine today, but what about the future? McKay reviews vehicle specifications, including items like ABS and ACL, regularly. This review is carried out on a rolling basis and ACL will be re-evaluated about every four years. So far it has always proved its worth on such occasions and McKay believes it will continue to do so.

There are 32 greasing points on the latest ERF 6x2 tractive unit, he says. This number easily makes the fitting of an ACL system a viable proposition. Some vehicle manufacturers have taken a conscious decision not to fit sealed-for-life bearings believing that the supply of new grease pushes out any dirt and grit that has worked its way into the bearing.

In almost half a century, automatic chassis lubrication systems have come a long way. The use of grease instead of oil has removed the "messy" reputation of the early systems. Today's systems have developed to such an extent that items such as clutch bearings and brake crossshafts on on which overgreasing has to be avoided, can be lubricated automatically.

While, in the past, Conoco's semitrailers have not been fitted with ACL systems, McKay is currently evaluating such a fitment. Intertube's XL system is specifically designed for trailer lubrications and takes its power from the brake light circuit — leaving it totally independent of the tractive unit. Costs, excluding fitting, range from 2346 for a 10-point unit to 2711 for the 60-point unit.

Fitting such a system to a trailer, with fewer moving parts than the tractive unit itself, may seem a little extravagant. However, trailers are generally the more neglected part of a combination and they are kept for a lot longer than the tractive unit — allowing longer pay-back periods to become attractive.

Transport maintenance managers who may have formed their opinions about ACL in the "messy" days of the oil-only systems should re-evaluate them occasionally to assess any changes. McKay says that there were some problems with the old systems, but "they are very few and far between now". Installing a system on a vehicle saves the fitter doing laborious greasing over and over again and it cannot miss out a nipple.

While each operation is different, Conoco believes that ACL is cost effective and Mercedes-Benz is installing systems on the production line. Both companies ensure that extras are reliable and earn their keep. It has taken almost half a century, but perhaps for automatic chassis lubrication, the time has come.

Interlube Turbo 61 Vogel Turbo 62