Longevity Cummins

Page 118

If you've noticed an error in this article please click here to report it so we can fix it.

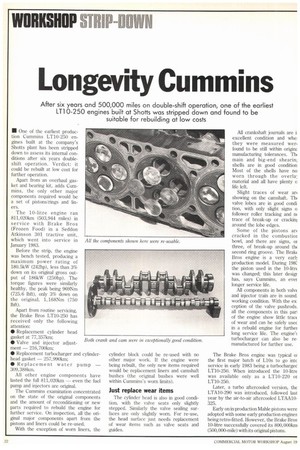

After six years and 500,000 miles on double-shift operation, one of the earliest [Ti 0-250 engines built at Shot-ts was stripped down and found to be suitable for rebuilding at low costs

• One of the earliest production Cummins LT10-250 engines built at the company's Shotts plant has been stripped down to assess its internal conditions after six years doubleshift operation. Verdict: it could be rebuilt at low cost for further operation.

Apart from an overhaul gasket and bearing kit, adds Cummins, the only other major components required would be a set of pistons/rings and liners.

The 10-litre engine ran 811,020Ian (503,944 miles) in service with Brake Bros (Frozen Food) in a Seddon Atkinson 301 tractive unit,, which went into service in January 1983.

Before the strip, the engine was bench tested, producing a maximum power rating of 180,5kW (242hp), less than 3% down on its original gross output of 186kW (250hp). The torque figures were similarly healthy, the peak being 969Nm (725.6 lbft), only 3% down on the original, 1,168Nm (750 lbft).

Apart from routine servicing, the Brake Bros LT10-250 has received only the following attention: • Replacement cylinder head gasket at 77,357km;

• Valve and injector adjustment — 216.700km;

• Replacement turbocharger and cylinderhead gasket — 257,990km; • Replacement water pump 309,388km.

All other engine components have lasted the full 811,020km — even the fuel pump and injectors are original.

The Cummins examination concentrated on the state of the original components and the amount of reconditioning or new parts required to rebuild the engine for further service. On inspection, all the original major components apart from the pistons and liners could be re-used.

With the exception of worn liners, the cylinder block could be re-used with no other major work. If the engine were being rebuilt, the only new items required would be replacement liners and camshaft bushes (the original bushes were well within Cummins's worn limits).

Just replace wear items The cylinder head is also in good condition, with the valve seats only slightly stepped. Similarly the valve sealing surfaces are only slightly worn. For re-use, the head surface just needs replacement of wear items such as valve seats and guides.

All crankshaft journals are i: excellent condition and whe: they were measured wen found to be still within origins manufacturing tolerances. Tho main and big-end shearinl shells are in good condition Most of the shells have no worn through the overla: material and all have plenty a life left.

Slight traces of wear an showing on the camshaft. Tho valve lobes are in good condi tion, with only slight signs a follower roller tracking and no trace of break-up or cracicinr around the lobe edges.

Some of the pistons aro cracked in the combustior howl, and there are signs, or three, of break-up around tho second ring groove. The Brako Bros engine is a very ear13 production model. During 198: the piston used in the 10-litro was changed; this later desigr has, says Cummins, an ever longer service life.

All components in both valvt and injector train are in sound, working condition. With the ex

ception of the valve puslu-ods, all the components in this par

of the engine show little tract of wear and can be safely use in a rebuild engine for further

long service life. The engine': turbocharger can also be re. manufactured for further use.

The Brake Bros engine was typical o: the first major batch of LlOs to go intc service in early 1983 being a turbochargec LT10-250. When introduced the 10-litre was available only as a LT10-220 ix LT10-250.

Later, a turbo aftercooled version, the LTA10-290 was introduced, followed last year by the air-to-air aftercooled LTAA10325.

Early on in production Mahle pistons were adopted with some early production engines being retro-fitted. However, the Brake Bros 10-litre successfully covered its 800,000km (500,000-mile) with its original pistons.