COMING SOON TO YOUR SCREEN!

Page 32

Page 33

Page 34

If you've noticed an error in this article please click here to report it so we can fix it.

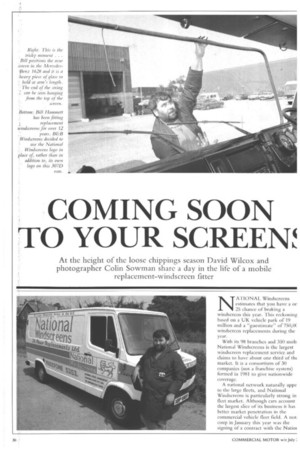

At the height of the loose chippings season David Wilcox and photographer Colin Sowman share a day in the life of a mobile replacement-windscreen fitter

NAT1ON A L Windscreens estimates that you have a or 25 chance of braking a windscreen this year. This reckoning based on a UK vehicle park of 19 million and a "guestimate" of 750,0( windscreen replacements during the year.

With its 98 branches and 330 mob: National Windscreens is the largest windscreen replacement service and claims to have about one third of tht market It is a consortium of 30 companies (not a franchise system) formed in 1981 to give nationwide Coverage.

A national network naturally appe to the large fleets, and National Windscreens is particularly strong in fleet market. Although cars account the largest slice of its business it has better market penetration in the commercial vehicle fleet field. A not; coup in January this year was the signing of a contract with the Natio' ght Consortium, which covers )00 vehicles.

.ach of the 30 member companies bin National Windscreens retains its 1 identity and can receive calls either n its local customers or relayed via National Windsreens 24 hour ,!fone 5353 switchboard in :sterfield.

'he windscreen replacement business hanging fast as toughened glass gives Ito laminated screens and direct ing (sometimes called bonded ang) gains acceptance among vehicle tufacturers.

'o see the effect of these changes CM at a day with one of National ldscreens' mobiles and watched r/manager Bill Ilarnmett at work. fle went to the Newmarket branch of B Windscreens which, with 22 riches in East Anglia and the )ining regions, is one of the largest Tanks in the National Windscreens sortitim.

,Iewmarket was a deliberate choice; idscreen replacement in East Anglia is her than the national average. Several ors contribute towards this. Car nership is higher (national average is cars per 1,000 people; in East Anglia ; 328 per 1,000). And although there laic motorway mileage (only the 1) the roads are frequently flat and

with vehicles passing close to each er at speed.

:he vital ingredient to add to this mix tones and they are there too. Many the roads are bounded by fields, and icultural tractors corning onto the d (particularly in the sugar beet son in late autumn) inevitably drag a tam amount of stones and soil with here is also a surprising amount of ilage in the area: a quarter of B&B's work is on commercial vehicles (including vans). Because commercial screens are more expensive they account for around 35 per cent of B&B's turnover.

Commercial vehicle speeds may be slower than cars', but the sheer size of a lorry screen puts it at risk. And while stones may be deflected off raked car windscreens the near-vertical angle of a commercial screen increases its vulnerability.

The average National Windscreens company branch has three vans. Escort vans are the most popular choice, but larger panel vans. arc also used to handle the extra size and weight of commercial screens.

Bill Hammett was driving a Mercedes-Benz 307D van the day we spent with him. The Mercedes is a popular choice among the windscreen

replacement companies because of its ' vertical sides — they allow the screen , racks inside to be canted over and still leave a reasonable amount of floor space.

Driving out to our first call in Bury St Edmunds, Bill Hammett explained that the advent of laminated screens has radically cut the amount of roadside replacement work. Because the laminated glass does not craze or shatuir the vehicle can still be driven, and so replacement is usually done at a time and place convenient to the driver.

Now, about the only volume-selling vehicle that does not have a laminated screen as original equipment is a Mini: But it takes a long time for all the older vehicles with toughened screens to disappear from the roads. Proportionately, there are more vans and lorries with toughened screens because the switch to laminated was made slightly later in the commercial vehicle industry.

Our first call in Bury St Edmunds was to replace the laminated screen in a Ford Fiesta. Bill said that this was about as simple as they come and it took him just 15 minutes.

Bill's second job was to replace the shattered screen in a builder's Bedford HA van.

Because it was a toughened screen in the S-registered HA Bill taped a blanket to the dashboard to catch the myriad of glass fragments. He had already taken care to tape over the demister vents.

The van's owner had, sensibly, specified a laminated replacement screen — the price premium was about 10 per cent — and Bill fitted this using the conventional 'stringing-in" method.

First, the rubber seal is fitted round the edge of the new screen and the string is inserted in the channel around the rubber seal. Then, to ensure a watertight seal, a ribbon of non-hardening sealer is run round the outside of the rubber seal with an extrusion gun.

Then the screen is offered up to the aperture and, working from the inside of the vehicle, the fitter slowly pulls away the string. This eases the lip of the rubber seal over the edge of the body . aperture, locating the screen.

Another ribbon of non-hardening sealer is applied between the outside of the screen and the inside of the rubber seal.

Finally, there is the tidying-up to do. This includes removing excess sealer, replacing any trim strips, cleaning the new screen and remembering to transfer the tax disc and any interior windscreenmounted mirror.

"Stringing-in" is the most common method of securing a windscreen. Some screens are "hooked-in", which means that the rubber seal is left in position on the body and the screen is eased into it. This technique is used on certain Leyland models such as the Terrier, Mini and Range-Rover.

On a few cars, such as the MGB and Midget, the windscreen is replaced by unscrewing the frame around it.

The fourth method is the one that is rapidly gaining favour — direct (or bonded) glazing. The Rover SD1 was the first mass produced UK car to use direct glazing and it was followed by the Sierra and the Maestto. Now the list of direct-glazed cars has grown to include Audi, Volvo, Renault, Lancia, Vauxhall, Alfa Romeo and many Japanese cars.

To date there is only one commercial vehicle with direct glazing — the Leyland Roadrunner, which won the Glass and Glazing Federation's 1985 Vehicle Safety Award. Many coaches have direct glazing, however, because it adds strength to their structure. The elimination of the conventional rubber seal also produces a smoother, neater exterior profile. There is a production advantage too because robots equipped with suckers can position and fit a direct

glazed screen, whereas they cannot wield a piece of string.

Direct glazing may suit the vehicle manufacturers, but it can cause problems when it comes to screen replacement.

The major requirement when fitting a new direct glazed screen is time. It takes longer to clean out the damaged screen because all the old adhesive has to be removed to give a flat, clean surface for the new one. And it takes time for the new adhesive to cure; the most common is a polyurethane cold-curing compound that needs around four hours to set, immobilising the vehicle. Trying to move the vehicle before the adhesive is cured can result in the screen popping out when the door is slammed!

This removes the possibility of whileyou-wait screen replacement. It is best to have the job done at the windscreen company's premises so that the clean and dry conditions needed can be guaranteed.

But adhesive curing times are being reduced and there is an alternative, faster direct glazing fixing method called a "hot kit". Its trade name is Solbit and it is made by 1.3ostik. It is a strip of polychloroprene rubber material with a fine wire running through it.

The strip of Solbit is positioned around the screen aperture and a 24V power source is applied to the two exposed ends of its internal wire. This softens the Scan and actuates a heatsensitive accelerator so that the screen can be pressed into position' and the adhesive quickly cured.

'[he hot kit reduces the whole windscreen replacement time (including cleaning out the broken one and the curing time) to just a couple of hours.

Removing a broken screen that has been installed with a hot kit is also easier; the power source can be reconnected to soften the material.

Bill Hammert's last job that day had been pre-booked. It was to replace the screen in a Mercedes-Benz 1628 Roadrunner tractive unit. The unit belonged to BRS Southern and was u on the company's British Sugar contract, working out of the Bury St Edmunds depot.

Although the screen on the Yregistered 1628 had only a small crack Bill said that BRS was Wise to replact because it would almost certainly star to run. He added that hauliers often c for a replacement screen just before d MOT test because a crack or stone ch in the driver's sight line is a legitiman test failure reason.

Bill said that the replacement of lor screens follows exactly the same principle as that used on car screens, the job is a little more awkard becaus. of the extra weight and size of the gla not to mention the height at which yk are working.

The very large coach screens, such those used on the new generation of double-deck or deck-and-a half coach. are very definitely a two-man job. Be recently did one where the screen aloi cost £800.

National Windscreens is not particularly active in the coach markel because most coachbuilders and importers prefer to keep screens at tht own service points or supply them direct to coach operators.

Bill started by sitting in the Merced driving seat and easing the rubber sea away from the top of the screen aperture, using a tool similar to a narrow paint scraper. As he did, the crack ran along the screen alarmingly but the laminated glass retained its rigidity.

With the top of the screen freed Bil was able to lift it clear from the outsi He strung-in the new screen in the ut way, but did not use non-hardening sealer, explaining that it should not b necessary because the water does not on the relatively upright screen.

The whole job took under 20 mine not all lorries are quite as quick. The ERF B-series screen is notoriously tri because it is so wide and unwieldy. Particularly upright screens such as th in the MAN cab and the old Leyland Ergornatic cab are difficult because th is an awkward moment when the unsecured screen has to rest in the aperture before it is strung in — only windscreen wipers help to hold it in position.

Bill also cited the Scania cab when fitted with the external visor as a tricl job. Because the visor is a very close it impedes the top of the screen durin fitment.

It had been a quiet day for Bill Hammett. He and his fellow B&B fit would normally replace about six or seven screens a day, but they said the weather was too good when CM was there. Rain is good for their business because it washes mud and stones off the fields and onto the roads.

July is also the favourite month for surface-dressing of roads and this is guaranteed to get the chippings flying But the roads around Newmarket remained undressed.