LIGHTWEIGHT DRAWBARS FOR MULTIPLE DELIVERIES b„......

Page 71

Page 73

If you've noticed an error in this article please click here to report it so we can fix it.

An improvement in vehicle/driver utilization of 70 per cent is anticipated by the Gerrards company from the use of six Bedford KGE rigid chassis converted by York to haul DB8 drawbar trailers on multiple deliveries of fruit and vegetables on selected routes

WHETHER or not the lightweight drawbar trailer outfit has a future in multipledrop delivery work is a question of major importance to a large section of the industry.

The staff of the York Trailer Company's Truck Equipment Division, Watford, Herts, believe that the demand for smaller drawbar outfits for this type of application will progressively increase. And York head office reports an upsurge of interest in lighter drawbars in the areas covered by the nine other divisions including demountablebody types and dolly-coupled units.

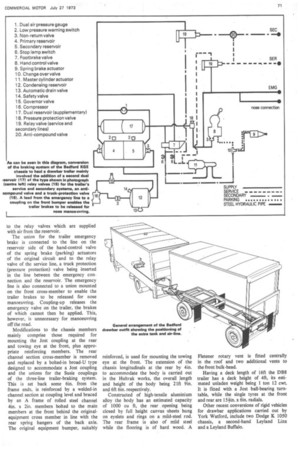

York Watford gives the example of a current conversion job for G. M. Gerrards Ltd, Park Royal, London, which involves the modification of six Bedford KGE 12.35-ton-gvw chassis /cabs of 193in. wheelbase to haul York DB8 8-ton-gvw trailers with single-tyred axles.

The converted prime-movers are equipped with Hultrak Hultralite boxvan bodies of aluminium construction (at the Hultrak works) while timber bodies are transferred from rigid chassis in the Gerrards' fleet to the York trailer chassis, both the truck and the trailer being fitted with Ratcliff electrically operated tail-lifts. A payload of 81 torts is carried by the prime movers while the trailers have a payload capacity of 6 tons.

The outfits are the first drawbar vehicles to be employed by Gerrards who believe that their use will enable vehicle/driver utilization to be increased by some 70 per cent on selected routes. On a typical run of 80 miles the trailer will be left at a site after the outfit has covered about 40 miles and the driver will make additional deliveries with the prime mover.

Following normal Gerrards' practice, the produce will be carried on trolleys to facilitate handling between the vehicle and the points of delivery. Twenty-four trolleys will be loaded on the prime mover of the drawbar outfit and 17 on the trailer, unloading being performed with the aid of the Ratcliff tail-lifts.

Modification of the air /hydraulic braking system of the Bedford chassis is basically similar to that applied to the vehicle when it converted to a six-wheeler, but an extra twin tank air reservoir is fitted to provide sufficient reserve capacity for the three-line trailer brakes. The regulations require that this capacity is eight times the air volume of the brake chambers and while the original reservoir capacity could cater for the braking of one additional axle, it would not be sufficient for two axles.

A supplementary twin tank reservoir is installed at the rear of the original-equipment dual reservoir and is connected in parallel to it. Two relay valves are incorporated in the system, one for the service brake and one for the secondary, the valves being bolted to the inside of the cross-member between the rear hanger brackets of the back axle.

The valve for the trailer service system is connected to the service line of the original circuit and the secondary valve to the secondary line, an anti-compound valve being inserted in the circuit between the lines on the trailer side of the valves to obviate dual operation of the two systems. "T" pieces on the air /hydraulic unit (master cylinder actuator) are used to connect the service and secondary lines to the relay valves which are supplied with air from the reservoir.

The union for the trailer emergency brake is connected to the line on the reservoir side of the hand-control valve of the spring brake (parking) actuators of the original circuit and to the relay valve of the service line, a truck protection (pressure protection) valve being inserted in the line between the emergency connection and the reservoir. The emergency line is also connected to a union mounted on the front cross-member to enable the trailer brakes to be released for nose manoeuvring. Coupling-up releases the emergency valve on the trailer, the brakes of which cannot then be applied. This, however, is unnecessary for manoeuvring off the road.

Modifications to the chassis members mainly comprise those required for mounting the Jost coupling at the rear and towing eye at the front, plus appropriate reinforcing members. The rear channel section cross-member is removed and replaced by a bolted-in broad-U type designed to accommodate a Jost coupling and the unions for the Susie couplings of the three-line trailer-braking system. This is set back some 6in. from the frame ends, is reinforced by a welded-in channel section at coupling level and braced by an A frame of rolled steel channel 4in. x 2in. members bolted to the main members at the front behind the originalequipment cross member in line with the rear spring hangers of the back axle. The original equipment bumper, suitably reinforced, is used for mounting the towing eye at the front. The extension of the chassis longitudinals at the rear by 4in. to accommodate the body is carried out in the Hultrak works, the overall length and height of the body being 21ft 9in. and 6ft 6in. respectively.

Constructed of high-tensile aluminium alloy the body has an estimated capacity of 1000 cu ft, the rear opening being closed by full height canvas sheets hung on eyelets and rings on a mild-steel rod. The rear frame is also of mild steel while the flooring is of hard wood. A

Fletener rotary vent is fitted centrally in the roof and two additional vents to the front bulk-head.

Having a deck length of 16ft the D88 trailer has a deck height of 4ft, its estimated unladen weight being 1 ton 12 cwt. It is fitted with a Jost ball-bearing turntable, while the single tyres at the front and rear are 154in. x 6in. radials.

Other recent conversions of rigid vehicles for drawbar applications carried out by York Watford, include two Dodge K 1050 chassis, a second-hand Leyland Linx and a Leyland Buffalo.