Lorry Bodies to Meet

Page 54

Page 55

If you've noticed an error in this article please click here to report it so we can fix it.

THE BUILDER'S

SPECIAL NEEDS THE builder's lorry has hinged or fixed sides, the former type facilitating unloading, particularly in the case of a loose load, such as sand or rubble. The timber merchant's lorry is similar, having a gantry at the back of the cab.

Usually the gantry is made as a separate unit of uprights, a cross-bar and struts, which is bolted inside the body. If the sides be hinged, the gantry uprights form a shutting surface. The other method is for these uprights to constitute the front pillars of the. body.

With a 1-ton or 30-cwt. lorry, there is usually a pair of diagonal struts under the cross-bar of the gantry, the lower ends of which are secured to the uprights. If greater rigidity be required, a pair of struts runs from the back of the uprights down to the floor. This type of tie also stiffens the body, because it may be bolted to the sides, in addition to the bottom framework.

Strut Construction.

When there are rear struts and the body sides are hinged, the lower part of the strut is arranged so that the body side rests against it when closed. A strut of angle iron is arranged so that one side of the angle is let flush into the top of the bottoni side, whilst the inside edge of the same member has the other part of the angle let into it in a similar manner to form a smooth surface.

For heavier loads, the front gantry is supplemented by a centre bolster. The largest lorries of this class are for transporting constructional ironwork. The centre bolster is usually of the trestle type, and for a trailer a high trestle in front and a low one at the rear is a convenient arrangement, 1336 because both may be removed if no sloping load is to be carried.

To secure the trestle in position on a platform lorry or trailer, its bottom rail, also the side rail of the platform, have tapped plates in order that a screw with a lever head may be engaged from the outside. Alternatively, pins may be dropped through the bottom cross-rail of the trestle into lined holes in the body crossbearers. Thousands of tons of glass are used annually in house and shop construction, and most of it is transported in specially designed vehicles. Glass is carried vertically, because in this way it is easier to handle and less liable to fracture than in the horizontal position. Moreover, it would be impracticable to carry very large sheets otherwise.

An ordinary lorry is adapted for transporting a load of glass by equipping it with an outside rack on the near side. The bottom of the rack is a few inches above the ground, in order that the overall height shall be restricted so far as possible. Smaller sheets of glass are carried inside the body. The inside rack is doublesided and stands in the centre of-the floor, or is placed on the off side, where it helps to ensure a better distribution of the load, with an outside rack.

Details of Racks for Plate Glass.

The off-side rack will carry a wide range of sizes of glass if it has outer and inner sloping supports. The outer portion has the usual bottom trough and is for the larger sheets. The inner part of the rack is for the smaller pieces of glass, which are carried in a bottom trough, or on a midway shelf.

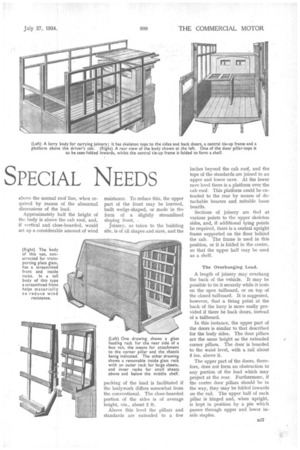

The plate-glass van with a pair of inside racks is as high as a doubledeck bus. The sides are boarded or of skeleton construction, and a set of detachable stump-hoopsticks with a loose sheet allows the load to project

above the normal roof line, when required by reason of the abnormal dimensions of the load.

Approximately half the height of the body is above the cab roof, and, if vertical and close-boarded, would set up a considerable amount of wind

resistance. To reduce this, the upper part of the front may be louvred, built wedge-shaped, or made in the form of a slightly streamlined

sloping front. .

Joinery. as taken to the building site, is of all shapes and sizes, and the packing of the load is facilitated if the bodywork differs somewhat from the conventional. The close-boarded portion of the sides is of average height, viz., about 2 ft.

Above this level the pillars and standards are extended to a few inches beyond the cab roof, and the tops of the standards are joined to an upper and lower rave. At the lower rave level there is a platform over the cab roof. This platform could be extended to the rear by means of detachable bearers and suitable loose boards.

Sections of joinery are tied at various points to the upper skeleton sides, and, if additional tying points be required, there is a central upright frame supported on the floor behind the cab. The frame is used in this position, or it is folded in the centre, so that the upper half may be used as a shelf.

The Overhanging Load.

A length of joinery may overhang the back of the vehicle. It may be possible to tie it securely while it rests on the open tailboard, or on top of the closed tailboard. It is suggested, however, that a tieing point at the back of the lorry is more easily provided if there be back doors, instead of a tailboard.

In this instance, the upper part of the doors is similar to that described for the body sides. The door pillars are the same height as the extended corner pillars. The door is boarded to the waist level, with a rail about 8 ins, above it.

The upper part of the doors, therefore, does not form an obstruction to any portion of the load which may project at the rear. Furthermore, if the centre door pillars should be in the way, they may be folded inwards on the rail. The upper half of each pillar is hinged and, when upright, is kept in position by a pin which passes through upper and lower inside staples.